Plastic molding processes are essential in the manufacturing industry, enabling the production of a wide range of plastic products. This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into choosing the right process for your custom plastic parts.

What is Plastic Molding Techniques?

Plastic molding is a manufacturing process where molten or softened plastic is shaped into specific forms using molds. The process ensures precise, consistent, and repeatable parts by controlling material flow, temperature, and pressure.

Zhongde Plastic Molding Service

Types of Plastic Molding Processes

Plastic molding encompasses a diverse set of techniques that transform raw plastic materials into finished products. Types of plastic molding process has its own unique characteristics and applications. Here are 6 common plastic molding processes as below:

Plastic Injection Molding Process

Plastic injection molding is a custom plastic molding process where plastic pellets are melted and injected into a mold to form precise shapes. It includes material preparation, melting, injection, cooling, and part ejection. This method delivers consistent, high-volume production with minimal waste, but mold design can be costly and small runs may be less economical.

Plastic Injection Molding Material:

Common materials used in plastic injection molding include thermoplastics such as polypropylene (PP), polyethylene (PE), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and nylon (PA). Additives like colorants or glass fibers can be incorporated to enhance appearance or strength.

Common Uses of Plastic Injection Molding Techniques:

Plastic injection molding is widely used to manufacture a variety of parts across industries. It produces components with precise shapes and consistent quality, from small precision parts like connectors and gears to larger items such as housings, containers, and automotive panels. The process also allows for incorporating complex features, threads, or inserts, making it suitable for products that require both functionality and repeatability.

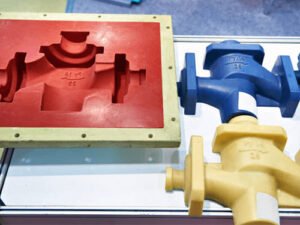

Plastic Compression Molding

Compression molding is a plastic molding process that involves placing a pre-measured amount of plastic material into a heated mold cavity. The mold is then closed, and pressure is applied to compress and shape the material. This process is commonly used for manufacturing larger, thicker parts such as automotive components, appliance parts, and electrical insulators.

Plastic Compression Molding Material:

Common materials used in plastic compression molding include thermosetting plastics such as phenolic, epoxy, melamine, and polyester resins, as well as certain thermoplastics that can be compression molded, including UHMW and PTFE.

Common Use of Plastic Compression Molding Techniques:

Plastic compression molding is used to produce durable parts such as electrical housings, automotive components, industrial machinery parts, and kitchenware, providing consistent strength and material distribution.

Plastic Blow Molding

Blow molding is used to create hollow plastic parts, such as bottles, containers, and automotive fuel tanks. It involves melting plastic resin and extruding it into a tube-like parison. The parison is then placed in a mold cavity, and compressed air is blown into it to expand and conform the plastic to the mold’s shape.

Plastic Blow Molding Material:

Common materials used in plastic blow molding include thermoplastics with good melt strength and flexibility, such as PE,PP, PC, and PET.

Common Use of Plastic Blow Molding Techniques:

Blow molding is an ideal process for manufacturing plastic water bottles. It allows for the production of hollow containers with consistent wall thickness and intricate shapes. The process’s versatility enables the creation of various bottle designs, including ergonomic grips, curved necks, and custom branding options.

Plastic Extrusion Molding

Extrusion molding is a continuous process where plastic material is melted and forced through a die to form a specific cross-sectional shape. Plastic extrusion offers high efficiency and low cost for long production runs, allowing the creation of complex cross-sections with consistent quality. However, it is less suitable for intricate 3D shapes, and precise die design is required to maintain dimensional accuracy.

Plastic Extrusion Molding Material:

Common materials used in plastic extrusion molding include PE, PP, PVC, PS, and ABS.

Common Use of Plastic Extrusion Molding Techniques:

Plastic extrusion allows continuous production of uniform profiles, tubes, sheets, and films with consistent dimensions and material properties.

Plastic Rotational Molding

Rotational molding, also known as rotomolding, is a process that involves rotating a mold filled with powdered plastic material in an oven. The rotation allows the plastic to evenly coat the mold’s inner surface and form the desired shape as it melts and fuses together.

Plastic Rotational Molding Material:

Common materials used in plastic rotational molding include PE, HDPE, LDPE, PP, and PVC.

Common Use of Plastic Rotational Molding Techniques:

Rotational molding is often employed for manufacturing kayaks. The process allows for the production of large, seamless, and durable plastic shells. Rotomolded kayaks offer excellent impact resistance, buoyancy, and weight distribution, making them suitable for recreational and professional use in water sports.

Plastic Thermoforming

Thermoforming is a plastic molding process that uses heat to soften a plastic sheet, which is then shaped over a mold using vacuum or pressure. It is cost-effective for medium to large parts, offering fast production and design flexibility. However, it has lower precision and limited suitability for very complex or thick parts.

Plastic Thermoforming Material:

Common materials used in plastic thermoforming include PET, PVC, PS, PP, and ABS.

Common Use of Plastic Thermoforming Techniques:

Thermoforming is commonly used for producing disposable food containers made of plastic. The process allows for efficient and cost-effective production of containers with various shapes and sizes. Thermoformed containers offer good heat resistance, easy stackability, and excellent clarity, making them suitable for food packaging and takeout applications.

Factors to Consider When Choosing a Plastic Molding Process

When choosing a plastic molding process, there are several key factors to consider:

Part Design and Complexity:

Evaluate the complexity of your part design and determine if the molding process can effectively reproduce the desired features. Some processes may be better suited for intricate designs, while others are more suitable for simpler shapes.

Production Volume:

Consider the desired production volume. Some processes, like injection molding, are well-suited for high-volume production, while others, like compression molding or rotational molding, are better for smaller or medium production runs.

Cost Considerations:

Analyze the cost implications of each molding process. This includes tooling costs, material costs, labor costs, and any secondary operations required. Consider the overall cost-effectiveness of the process for your specific project.

Material Selection:

Different molding processes may have limitations on the types of materials that can be used. Ensure that the chosen process is compatible with the desired material properties and characteristics.

Click to learn how to choose the right plastic materials for your molding parts.

Time Constraints:

Evaluate the time constraints of your project. Some processes may have shorter cycle times and faster production rates, while others may require more time for cooling or curing.

Part Quality Requirements:

Consider the desired quality and precision of the final molded parts. Evaluate the dimensional accuracy, surface finish, and other quality parameters that are important for your application.

Choosing the Right Type of Plastic Molding for Your Project

At Zhongde, we pride ourselves on being a reliable on-demand manufacturer that provides types of plastic molding process to meet our customers’ unique requirements. You can reach out to us for a prompt quote and exceptional assistance.