CNC plastic machining is a precision manufacturing to creation of highly accurate, complex, and customizable plastic components. It is an alternative to traditional injection molding.

Can Plastic Be CNC Machined?

The answer is a definitive yes. Plastic, as a versatile material class, is very well suited for CNC machining. Although plastics are softer, more prone to melting, and sometimes more flexible. Modern CNC machinery and tooling have adapted to these characteristics. This process produces precise and repeatable parts with excellent surface finishes, making it ideal for prototyping, small batch production, and even full-scale manufacturing of CNC plastic parts across various industries with custom mining parts or marine parts.

Why Does Plastic CNC Machining Matter?

Plastic CNC machining matters because it offers several compelling advantages over other manufacturing methods:

High Precision and Repeatability

CNC plastic machining delivers parts with tight tolerances and intricate geometries that are difficult to achieve with conventional methods.

Rapid Prototyping and Production Flexibility

It allows quick turnaround from design to physical part, allowing engineers to test and refine prototypes efficiently, enabling fast prototyping and small to medium batch production without expensive tooling costs.

Wide Material Compatibility

CNC machining can handle a broad spectrum of plastics for cnc applications—from general-purpose to high-performance polymers—ensuring optimal material properties for each use case.

Excellent Surface Finish

Precision machined plastic parts often require minimal finishing due to the smooth, burr-free surfaces achievable with CNC machining.

Cost Efficiency

Compared to molding or additive processes, plastic machining is often more economical, especially for low-volume production or prototypes.

Customization and Easy to Modify

Machined plastic parts can be easily customized, with rapid design changes accommodated through software rather than costly physical molds.

CNC Plastic Machining

What Types of Plastic Materials Are Suitable for CNC Machining?

ABS CNC Machining

A cost-effective, impact-resistant plastic that’s easy to machine, ABS is widely used for prototypes, enclosures, and consumer goods like electronics housings.

PC CNC Machining

Known for its exceptional impact strength and transparency, Polycarbonate is ideal for protective covers, optical lenses, and safety equipment. Precision plastic machining of PC requires careful heat management to avoid stress cracking or warping.

POM CNC Machining

With high stiffness, low friction, and excellent dimensional stability, POM is perfect for precision machined plastic parts like gears, bearings, and valve components. It is wear resistant.

Nylon CNC Machining

Durable and wear-resistant, Nylon is a top choice for bushings, rollers, and gears in plastic precision machining. Its tendency to absorb moisture can affect dimensions, so pre-drying is recommended before machining.

PMMA CNC Machining

Offering optical clarity and UV resistance, PMMA is used for lenses, signage, and decorative parts. Its brittleness requires slow cutting speeds and sharp tools to prevent cracking during CNC plastic machining.

PEEK CNC Machining

A high-performance plastic with superior heat and chemical resistance, PEEK is used in demanding applications like aerospace components and medical implants. It is requiring specialized tools for precision plastic machining due to its toughness.

For more detailed comparison, refer to our plastic material selection guide to choose the best-fit polymer for your CNC machining project.

CNC Plastic Machining Techniques

CNC plastic machining employs several techniques to shape plastics into precise components, each suited to specific part geometries and functional needs.

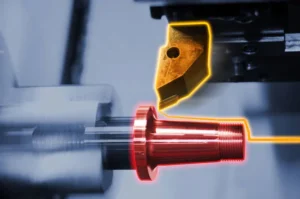

Plastic CNC Milling

CNC milling uses a rotating milling cutter to remove material from a plastic workpiece, creating complex shapes like slots or contoured surfaces. Machines are categorized as 3-axis mills, suitable for simpler designs, or multi-axis mills (4-axis or more).

Guidelines for CNC Milling:

- Use carbon tooling for thermoplastics reinforced with glass or carbon fibers to prevent tool wear.

- Employ clamps to secure the workpiece, enabling higher spindle speeds for smoother cuts.

- Design rounded internal corners and pockets using end mills to reduce stress concentration and improve part durability.

- Maintain low cutting speeds for heat-sensitive plastics to avoid melting.

- Ensure proper chip evacuation with air blasts to prevent tool clogging and surface imperfections.

Plastic CNC Turning

CNC turning involves securing a plastic workpiece on a lathe, which rotates against a cutting tool to create cylindrical parts like shafts or bushings. Variations include straight turning for uniform cuts and taper turning for conical shapes.

Guidelines for CNC Turning:

- Use a negative back rake on cutting edges to minimize rubbing and heat buildup.

- Apply generous relief angles to reduce friction and enhance tool life.

- Polish top surfaces to reduce material buildup and improve surface finish.

- Use fine C-2 grade carbide inserts for clean, precise cuts.

- Set feed rates at 0.015 IPR for rough cuts and 0.005 IPR for finishing cuts.

- Adjust clearance, rake, and side angles based on the plastic.

Plastic CNC Drilling

CNC drilling uses a drill bit to create precise holes in plastic blocks for fasteners or channels. The spindle lowers the drill onto the secured workpiece, with variations like upright or radial drill presses offering flexibility for different part sizes.

Guidelines for CNC Drilling:

- Keep drill bits sharp to avoid excessive stress, which can crack brittle plastics like Acrylic.

- Use a 90-118° drill bit with a 9-15° lip angle for most thermoplastics; use a 0° rake for Acrylic to prevent chipping.

- Ensure effective chip ejection to reduce friction and heat, using high-pressure air or vacuum systems.

- Limit drilling depth to 3-4 times the drill diameter to minimize heat buildup and stress.

- Reduce feed rate near the exit to prevent damage to the part’s surface or structure.

Tips for Successfully CNC Plastic Machining

Achieving optimal results in plastic precision machining requires attention to detail and adherence to best practices.

- Select Sharp, Specialized Tools: Use carbide tools with sharp edges and appropriate rake angles to minimize chipping and achieve smooth cuts.

- Optimize Cutting Parameters: Adjust spindle speed, feed rate, and depth of cut to reduce heat buildup, which can melt or warp plastics. Coolants or air pads help manage heat in CNC plastic processes.

- Avoid Overclamping: Excessive clamping pressure can deform soft plastics, leading to dimensional inaccuracies. Use jigs or soft pads to distribute pressure evenly during plastic machining.

- Ensure Effective Chip Removal: Soft plastics produce stringy chips that can clog tools. Use high-pressure air or vacuum systems to clear chips and maintain clean cuts in machined plastic parts.

- Design for Machinability: Incorporate rounded internal corners, thicker walls (>1.5 mm), and shallow cavities to simplify machining and reduce errors.

- Precondition Materials: Dry moisture-absorbing plastics before machining to prevent dimensional changes due to swelling, ensuring precision in machined plastic parts.

Conclusion

As industries demand ever-more intricate and precision plastic components, the role of CNC plastic machining continues to expand. Zhongde provide professional plastic CNC machining solutions with expert material selection guide and decades of experience in handling various CNC plastic materials.