Molded parts designing is complex and involves a multitude of factors such as functional requirements, material selection, and structural considerations. Various elements, including wall thickness, draft, ribs, holes, and bosses, must be carefully considered to create effective molded part designs. This blog explores fundamental guidelines for molded parts plastic boss design. Following these guidelines can improve moldability, enhance mold life, increase part durability, and reduce manufacturing costs.

What is Boss in Plastic Design for Molded Parts?

For plastic molded part design, understanding the concept of boss design is important. So, what exactly is a boss in the context of molded parts? In essence, a boss is a structural feature, a cylindrical projection with holes within molded parts.Common plastic injection molding boss types include solid, hollow, threaded, ribbed, blind, and through-hole bosses, each designed to meet specific strength, assembly, and manufacturing requirements.

They serve various functions, including but not limited to providing attachment points for screws, fasteners, or other assembly hardware. These features enable seamless assembly processes and ensure the structural integrity of the final product.

What is a Good Plastic Boss Design?

A good injection molding boss design is not just about creating a place for a screw or insert—it’s about ensuring strength, alignment, and manufacturability.

- Structural Support: A recessed or well-supported boss distributes stress more evenly and prevents cracking or deformation during assembly.

- Precise Alignment: Bosses can guide mating parts into position, ensuring accurate fit and reducing misalignment.

- Clean Aesthetics: Recessed bosses allow screws or fasteners to sit below the surface, resulting in a smoother, more finished appearance.

- Moldability: Good boss design considers draft angles, wall thickness, and core placement to ensure easy mold release and avoid defects like sink marks or warping.

Plastic Boss Design Guidelines for Molded Parts

The following is some boss design tips for molded plastic parts:

1. Base Radius for Bosses

To reduce stress, it’s essential to include a minimum radius at the base of a boss. The point where the boss meets the nominal wall is typically stressed, and stress will rise without a radius. However, the radius at the base of the boss should not exceed a maximum value to avoid thick sections. The recommended range for this base radius falls between 0.25 to 0.5 times the nominal wall thickness.

2. Spacing Between Bosses

Placing bosses too close to each other will create thin areas that are challenging to cool and can impact quality and productivity. Thin mold walls are hard to manufacture and can lead to issues like hot spots and uneven cooling, and results in reduced mold life. Therefore, it’s advisable to maintain a spacing between bosses of at least 2 times the nominal wall thickness.

3. Hole Base Radius for Bosses

Adding a radius to the core pin avoids sharp corners, making molding easier and reducing stress concentration. It’s suggested to have the radius at the hole’s base in the boss be 0.25 to 0.5 times the wall thickness.

4. Minimum Draft for Boss Outer Diameter

To ensure an easy demould, a suitable draft on the outer diameter (OD) of a boss is required. This draft is typically greater than or equal to 0.5 degrees.

5. Minimum Draft for Boss Inner Diameter

The designs need a minimum taper on the inner diameter(ID) of a boss for proper engagement with a fastener. The draft is on the boss’s inner walls, with a recommended minimum value of greater than or equal to 0.25 degrees. Not only does it allow for easy demould, but it also guarantees a proper and secure fit for fasteners.

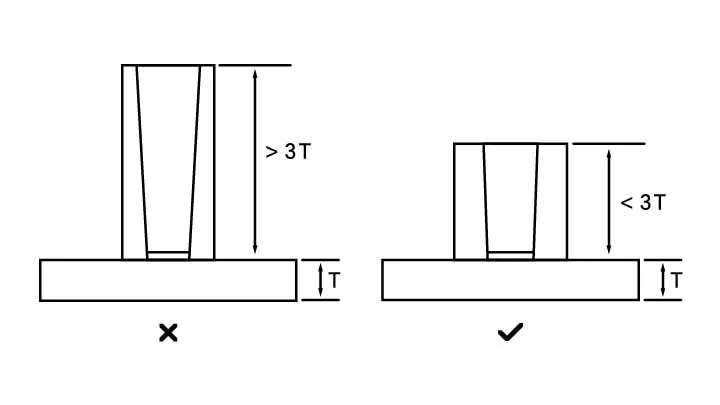

6. Optimal Boss Height to Outer Diameter Ratio

The advised boss height is less than three times the outer diameter (OD). Because too high a boss can result in undesired material mass and thick sections at the base. This is not easy to cool, and also extends the cycle time, and impacts the dimensional accuracy of cored holes.

7. Optimal Tip Radius for Bosses

To ensure their durability and longevity, it’s important to design a fillet with a specific minimum radius value at the tip of a boss. This radius will help to reduce stress.

8. Chamfer at the Top of Boss

For the top of a boss, it’s recommended to add a 30°–45° chamfer or a small radius to help guide screw insertion and reduce the risk of stress cracking.

9. Wall Thickness of Boss

The ideal injection molding Boss wall thickness should be about 60 percent of the nominal wall to prevent sinking issues. Exceeding this thickness can lead to voids, sink marks, and longer cycle times. However, if the boss is in a non-visible area, you can increase the wall thickness to increase higher stresses from self-tapping screws.

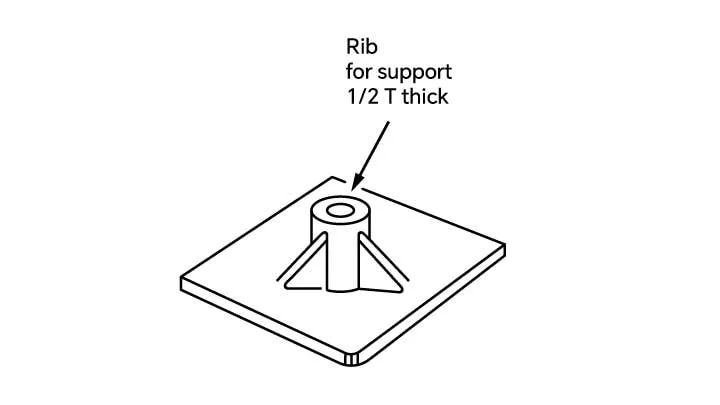

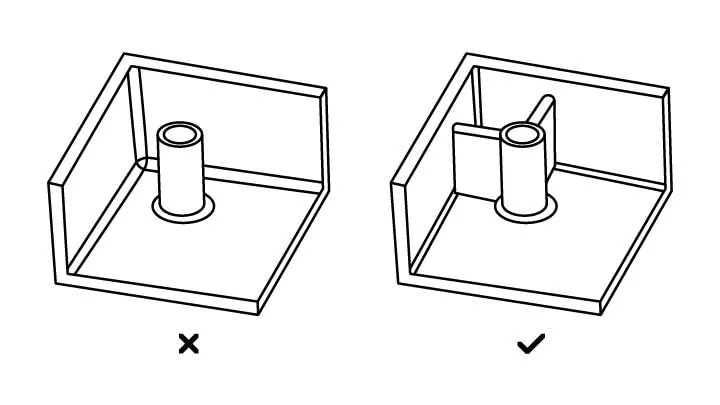

10. Standalone Boss

When dealing with bosses and other thick sections, coring is a recommended approach. Attaching the boss to the sidewall ensures even material flow and additional load distribution for the part. For improved rigidity and material flow, it’s best to connect a boss to the nearest side wall.

Common Issues and Solutions in Boss Design

Excessive Wall Thickness Causing Sink Marks

Bosses that are too thick compared to surrounding walls can lead to uneven cooling and sink marks. To prevent this, keep the boss wall thickness around 50-70% of the adjacent walls and consider adding ribs or hollow sections to maintain strength without excessive material.

Weak Structural Support Leading to Cracking or Warping

Tall or thin bosses without adequate reinforcement are prone to deformation or breakage during molding or use. Adding properly designed ribs and limiting the height-to-diameter ratio to about 3:1 improves structural integrity.

Insufficient Draft Angle Causing Ejection Difficulties

Boss sidewalls without a draft angle can cause the part to stick in the mold, increasing cycle time or damaging the part. Applying a draft angle of 1° to 2° ensures smooth mold release.

Sharp Corners Causing Stress Concentration

Sharp transitions between the boss and base can create stress points, leading to cracking. Incorporate fillets with a radius of 0.5–1 mm to distribute stress evenly.

Improper Top Chamfer Affecting Assembly

A boss top without a chamfer can make screw insertion difficult and cause stress concentrations. A chamfer of 30°–45° or a small radius improves assembly and reduces risk of damage.

Long Cooling Time Due to Boss Geometry

Large or thick bosses slow cooling, increasing cycle time. Optimize boss size and add cooling channels in the mold to improve cooling efficiency.

Material Properties Impacting Boss Performance

Material choice affects boss strength, shrinkage, and cooling behavior. High-shrinkage materials require tighter control of wall thickness, while low thermal conductivity materials may need enhanced cooling designs.

Conclusion with Plastic Boss Design Guideline

Bosses in injection molded parts are important features, often serving as anchors, supports, and facilitators of reliable assembly. These components play a significant role in ensuring the structural integrity and performance of the final product. Following to fundamental design guidelines is key to producing plastic parts with strong, functional, and visually appealing bosses. Do you need quality molded parts with a reliable boss design? Zhongde’s injection molding services are your ideal choice. Our experienced team is dedicated to meeting your specific requirements, offering a wide range of materials, surface finishes, and intricate geometries. We’re committed to delivering reliable solutions to meet your unique needs. Trust Zhongde for precise, efficient, and cost-effective plastic part manufacturing.

Optimize Your Molded Part Design Today!