Material hardness is a crucial aspect that defines a material’s resistance to deformation and wear. This fundamental property plays a pivotal role in various industries, from manufacturing to engineering. In this post, we embark on a journey to delve into the intricacies of material hardness, encompassing its types, testing methods, and significance in the world of materials science.

What is Material Hardness?

Material hardness is a fundamental mechanical property that measures a material’s resistance to deformation, indentation, scratching, or penetration. It signifies a material’s ability to withstand external forces without undergoing permanent changes to its shape or structure. In essence, material hardness indicates how resistant a material is to wear, abrasion, and impacts.

Hardness is a critical factor in material selection, as it directly influences a material’s suitability for specific applications. Different materials exhibit varying degrees of hardness, which impacts their performance in diverse scenarios. Whether designing cutting tools, evaluating structural components, or ensuring the durability of consumer products, understanding material hardness is pivotal in achieving optimal functionality and longevity.

What Are the Different Types of Material Hardness?

Material hardness is a multifaceted property, evaluated through distinct methods that offer insights into various aspects of a material’s resistance to deformation. Here are the different types of material hardness:

Scratch Hardness:

Scratch hardness gauges a material’s ability to resist surface abrasion and scratching. It involves sliding a harder material across the material’s surface, observing its resistance to scratching and wear.

Rebound Hardness:

Rebound hardness assesses material hardness by measuring the rebound height of an impact body dropped onto the material’s surface. This method is suitable for softer materials that may not undergo traditional indentation-based tests.

Indentation Hardness

Indentation hardness examines material resistance by measuring the indentation’s depth or size resulting from a controlled force applied to the material’s surface.

How to Test Material Hardness?

Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests:

The Brinell Test:

The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. The diameter of the resulting indentation is measured using a microscope. The Brinell hardness number (HB) is calculated using the load and the diameter of the indentation.

The formula for Brinell hardness is:

Where:

F – force, N

D – indenter diameter, mm

d – indentation diameter, mm

Rockwell Hardness Test:

The Rockwell hardness test measures the depth of indentation created by applying a preload and a major load to the material’s surface using a diamond cone or steel ball indenters. The Rockwell hardness number (HR) is determined based on the depth of indentation.

The formula for Rockwell hardness is:

where

N – scale factor depending on the scale used

s – scale factor depending on the scale used

d – depth of permanent indentation compared to minor load, mm

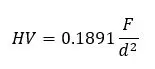

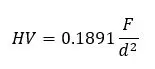

Vickers Hardness Test:

The Vickers hardness test utilizes a diamond pyramid indenter to create an indentation on the material’s surface under a specified load. The diagonals of the indentation are measured, and the Vickers hardness number (HV) is calculated.

The formula for Vickers hardness is

where

F – force, N

d – indentation diagonal, mm

Mohs Hardness Test:

The Mohs hardness test is a simple qualitative test that ranks minerals based on their scratch resistance. In this test, a mineral of known hardness is used to scratch another mineral. The relative ability to scratch or be scratched determines the Mohs hardness scale position.

Scleroscope Test:

The Scleroscope hardness test involves dropping a diamond-tipped hammer from a fixed height onto the material’s surface. The rebound velocity of the hammer is measured, and the Scleroscope hardness value (HS) is determined.

What Are Different Material Hardness Units?

Material hardness can be quantified using various units, each tailored to specific testing methods and industries. These units provide a standardized way to express the hardness of materials and facilitate comparisons. Here are some common material hardness units:

Brinell Hardness (HB):

Brinell hardness is expressed in Brinell units (HB). It measures the indentation diameter produced by a specified load applied to a material’s surface using a spherical indenter.

Rockwell Hardness (HR):

Rockwell hardness is represented by Rockwell hardness units (HR). It measures the depth of indentation created by applying a preload and a major load to a material’s surface using diamond cone or steel ball indenters. Different scales (A, B, C, etc.) are used for various materials and test conditions.

Vickers Hardness (HV):

Vickers hardness is denoted in Vickers hardness units (HV). It quantifies the hardness by measuring the diagonals of an indentation created by applying a specific load to a material’s surface using a diamond pyramid indenter.

Mohs Hardness (Mohs):

Mohs hardness is a relative scale without specific units. It ranks minerals based on their scratch resistance against each other, providing a qualitative measure of hardness.

Scleroscope Hardness (HS):

Scleroscope hardness is represented in Scleroscope units (HS). It measures the rebound velocity of a diamond-tipped hammer dropped onto the material’s surface, indicating its hardness.

The SI unit of hardness is the pascal (Pa), which is equivalent to N/m² (newtons per square meter). This unit is used to quantify the ability of a material to resist deformation and indentation. When discussing hardness, the unit pascal is often represented as N/mm², indicating newtons of force applied over a square millimeter of area.

Material Hardness Chart

Conclusion

Material hardness isn’t just a measurement; it’s a guiding principle. Proper testing is paramount for optimal material selection. With diverse methods available, consulting experts ensure well-informed decisions. Material hardness isn’t just a factor—it’s the foundation of excellence in engineering and innovation.

A material hardness chart showcases the hardness ratings of different materials, evaluated using various hardness scales. This tool allows for easy comparison between materials or the selection of the most suitable hardness test for a specific material.

The most commonly use Rockwell Hardness scales are HRA, HRB, HRC. Here is an example of a material hardness chart based on the Rockwell scale.

| Material | HRA | HRB | HRC |

| Brass | 50-80 | – | – |

| Mild Steel | – | 50-70 | – |

| Tool Steel | – | – | 50-65 |

| Hardened Steel | – | – | 55-68 |

| Stainless Steel | – | – | 20-60 |

| Aluminum | 20-40 | – | – |

| Titanium | – | – | 30-45 |

| Cast Iron | – | – | 20-45 |

| Copper | 30-70 | – | – |

| Nickel Alloys | – | – | 30-50 |

| Glass | 75-85 | – | – |

Material hardness is a crucial aspect that defines a material’s resistance to deformation and wear. This fundamental property plays a pivotal role in various industries, from manufacturing to engineering. In this post, we embark on a journey to delve into the intricacies of material hardness, encompassing its types, testing methods, and significance in the world of materials science.

What is Material Hardness?

Material hardness is a fundamental mechanical property that measures a material’s resistance to deformation, indentation, scratching, or penetration. It signifies a material’s ability to withstand external forces without undergoing permanent changes to its shape or structure. In essence, material hardness indicates how resistant a material is to wear, abrasion, and impacts.

Hardness is a critical factor in material selection, as it directly influences a material’s suitability for specific applications. Different materials exhibit varying degrees of hardness, which impacts their performance in diverse scenarios. Whether designing cutting tools, evaluating structural components, or ensuring the durability of consumer products, understanding material hardness is pivotal in achieving optimal functionality and longevity.

What Are the Different Types of Material Hardness?

Material hardness is a multifaceted property, evaluated through distinct methods that offer insights into various aspects of a material’s resistance to deformation. Here are the different types of material hardness:

Scratch Hardness:

Scratch hardness gauges a material’s ability to resist surface abrasion and scratching. It involves sliding a harder material across the material’s surface, observing its resistance to scratching and wear.

Rebound Hardness:

Rebound hardness assesses material hardness by measuring the rebound height of an impact body dropped onto the material’s surface. This method is suitable for softer materials that may not undergo traditional indentation-based tests.

Indentation Hardness

Indentation hardness examines material resistance by measuring the indentation’s depth or size resulting from a controlled force applied to the material’s surface.

How to Test Material Hardness?

Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests:

The Brinell Test:

The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. The diameter of the resulting indentation is measured using a microscope. The Brinell hardness number (HB) is calculated using the load and the diameter of the indentation.

The formula for Brinell hardness is:

Where:

F – force, N

D – indenter diameter, mm

d – indentation diameter, mm

Rockwell Hardness Test:

The Rockwell hardness test measures the depth of indentation created by applying a preload and a major load to the material’s surface using a diamond cone or steel ball indenters. The Rockwell hardness number (HR) is determined based on the depth of indentation.

The formula for Rockwell hardness is:

where

N – scale factor depending on the scale used

s – scale factor depending on the scale used

d – depth of permanent indentation compared to minor load, mm

Vickers Hardness Test:

The Vickers hardness test utilizes a diamond pyramid indenter to create an indentation on the material’s surface under a specified load. The diagonals of the indentation are measured, and the Vickers hardness number (HV) is calculated.

The formula for Vickers hardness is

where

F – force, N

d – indentation diagonal, mm

Mohs Hardness Test:

The Mohs hardness test is a simple qualitative test that ranks minerals based on their scratch resistance. In this test, a mineral of known hardness is used to scratch another mineral. The relative ability to scratch or be scratched determines the Mohs hardness scale position.

Scleroscope Test:

The Scleroscope hardness test involves dropping a diamond-tipped hammer from a fixed height onto the material’s surface. The rebound velocity of the hammer is measured, and the Scleroscope hardness value (HS) is determined.

What Are Different Material Hardness Units?

Material hardness can be quantified using various units, each tailored to specific testing methods and industries. These units provide a standardized way to express the hardness of materials and facilitate comparisons. Here are some common material hardness units:

Brinell Hardness (HB):

Brinell hardness is expressed in Brinell units (HB). It measures the indentation diameter produced by a specified load applied to a material’s surface using a spherical indenter.

Rockwell Hardness (HR):

Rockwell hardness is represented by Rockwell hardness units (HR). It measures the depth of indentation created by applying a preload and a major load to a material’s surface using diamond cone or steel ball indenters. Different scales (A, B, C, etc.) are used for various materials and test conditions.

Vickers Hardness (HV):

Vickers hardness is denoted in Vickers hardness units (HV). It quantifies the hardness by measuring the diagonals of an indentation created by applying a specific load to a material’s surface using a diamond pyramid indent.

Mohs Hardness (Mohs):

Mohs hardness is a relative scale without specific units. It ranks minerals based on their scratch resistance against each other, providing a qualitative measure of hardness.

Scleroscope Hardness (HS):

Scleroscope hardness is represented in Scleroscope units (HS). It measures the rebound velocity of a diamond-tipped hammer dropped onto the material’s surface, indicating its hardness.

The SI unit of hardness is the pascal (Pa), which is equivalent to N/m² (newtons per square meter). This unit is used to quantify the ability of a material to resist deformation and indentation. When discussing hardness, the unit pascal is often represented as N/mm², indicating newtons of force applied over a square millimeter of area.

Material Hardness Chart

A material hardness chart showcases the hardness ratings of different materials, evaluated using various hardness scales. This tool allows for easy comparison between materials or the selection of the most suitable hardness test for a specific material.

The most commonly use Rockwell Hardness scales are HRA, HRB, HRC. Here is an example of a material hardness chart based on the Rockwell scale.

| Material | HRA | HRB | HRC |

| Brass | 50-80 | – | – |

| Mild Steel | – | 50-70 | – |

| Tool Steel | – | – | 50-65 |

| Hardened Steel | – | – | 55-68 |

| Stainless Steel | – | – | 20-60 |

| Aluminum | 20-40 | – | – |

| Titanium | – | – | 30-45 |

| Cast Iron | – | – | 20-45 |

| Copper | 30-70 | – | – |

| Nickel Alloys | – | – | 30-50 |

| Glass | 75-85 | – | – |

Conclusion

Material hardness isn’t just a measurement; it’s a guiding principle. Proper testing is paramount for optimal material selection. With diverse methods available, consulting experts ensure well-informed decisions. Material hardness isn’t just a factor—it’s the foundation of excellence in engineering and innovation.