What is Polypropylene (PP)?

Advantages of Machining Polypropylene

Machining polypropylene offers numerous benefits, making it a top choice for manufacturers seeking efficiency and versatility: Ease of Machining: PP’s semi-crystalline structure allows for smooth cutting, enabling CNC polypropylene processes to achieve tight tolerances with minimal tool wear. Cost-Effectiveness: The low material cost of PP, combined with its machinability, reduces production expenses, making it ideal for both prototyping and high-volume manufacturing of machined plastic parts. Chemical Resistance: PP withstands corrosive substances, ensuring longevity in applications like chemical containers and piping systems. Lightweight Material: Among commodity plastics, polypropylene boasts one of the lowest densities, contributing to significant weight savings in final components. Sterilizability: PP’s ability to endure repeated autoclaving makes it a staple for medical components like syringes and surgical trays. Good Dimensional Stability: Machining PP can achieve tight tolerances due to its semi-crystalline nature, useful in applications requiring precision.

PP CNC Machining Service

Step-by-Step Workflow for CNC Polypropylene Machining

The CNC PP machining process requires careful planning and execution to achieve optimal results. Below is a detailed workflow for machining polypropylene:Material Selection and Preparation

Choose the appropriate PP grade (homopolymer or copolymer) based on application requirements. Pre-cut the raw sheet or rod stock to manageable sizes for CNC setup.Machine Setup

Configure CNC mills or lathes with robust fixturing to secure PP workpieces.Tool Selection

Opt for sharp, high-speed steel (HSS) or carbide tools with polished edges to minimize burrs and ensure clean cuts in CNC PP operations.Rough Cutting

Use initial cutting processes to bring the material close to the desired size and shape. This step removes excess material without focusing on precision.CNC Machining

Program the CNC machine with the final design specifications. Optimize settings for spindle speed, feed rate, and depth of cut.Chip Evacuation and Cooling

Employ air blasts, mist coolants, or water-soluble coolants to clear stringy chips and maintain optimal temperature at the cutting zone, preventing thermal deformation.Post-Machining Finishing

Deburr edges using manual or automated methods and inspect parts for dimensional accuracy and surface finish to ensure high-quality CNC polypropylene components.Common Challenges in Machining Polypropylene and Solutions

While machining polypropylene is generally straightforward, certain challenges can arise. Understanding these issues and their solutions is critical for successful CNC PP fabrication:Heat Sensitivity and Warping

Polypropylene has a relatively low melting point. Excessive heat generated during cutting can melt or deform the material. Solution: optimize cutting speeds and depths, apply coolants, and use intermittent cutting to allow the material to cool.Stringy Chip Formation

PP tends to produce long, stringy chips that can wrap around tools or workpieces, complicating chip evacuation. Solution: use sharp tools with polished flutes and implement effective chip clearance strategies such as air blowers or coolant flow.Workpiece Flexibility and Vibration

PP is less rigid compared to metals, which can cause vibrations and deflections during machining, leading to poor surface finish or dimensional inaccuracies. Solution: design custom clamps and fixtures that hold the part securely without distortion. Use softer jaw materials or distributed clamping pressure.Material Softness

PP’s relatively soft nature can result in burrs or rough surface finishes. Solution: Employ sharp tools with high cutting speeds and light feed rates to achieve smoother surfaces in PP CNC machining.Contamination Risk

In mixed-material shops, metal residues can contaminate PP parts, potentially causing cracks over time. Solution: Utilize dedicated polymer machining facilities to ensure contamination-free CNC PP production.Tools and Machines for Polypropylene Machining

Choosing the Right CNC Machine for PP

Basic Cutting Tools for PP Machining

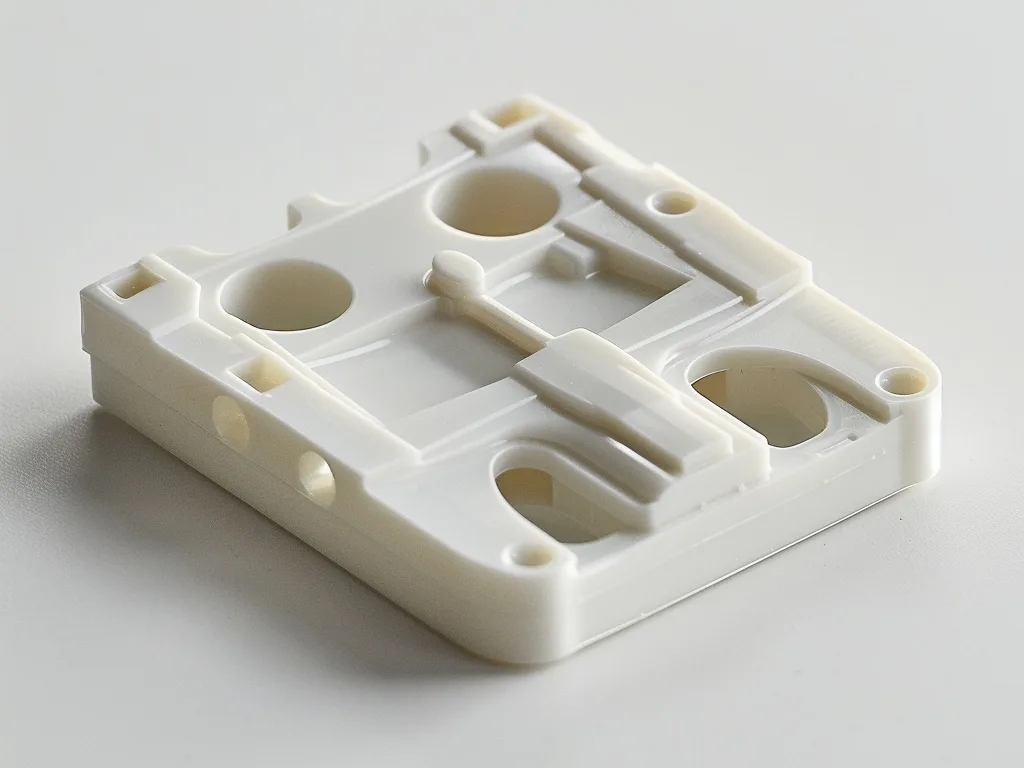

Applications of Machining Polypropylene

CNC polypropylene machining supports a wide range of industries due to PP’s versatile properties:- Medical Sector: Disposable syringes, instrument trays, diagnostic device parts, fluid delivery system components.

- Automotive Industry: Interior trim, fluid containers, and protective covers.

- Consumer Goods: Household items, containers, and packaging components.

- Industrial Equipment: Chemical tanks, pipe fittings, and electrical insulator components.

Partner Zhongde for CNC PP Machining

Although there are many challenges during the machining process, partner with experience manufacturer will solve the problem. Zhongde offers expert CNC PP machining services with advanced CNC mills and lathes, providing reliable custom cnc service that ensures tight tolerances and smooth surface finishes for PP components. Welcome to contact Zhongde and get custom PP CNC machining solutions.FAQs

CNC machining PP (polypropylene) differs from other plastics because PP is softer and more flexible, making it easier to machine but prone to melting or deforming if not cooled properly, while other plastics like ABS or PC may be harder, more brittle, or require different cutting speeds and tools due to varying strength and thermal properties.

Machining polypropylene involves cutting the material into shape, allowing for small production runs and custom parts with tight tolerances. Injection molding melts and injects PP into molds, suitable for high-volume production but less flexible for quick design changes.

Yes, CNC machining polypropylene is cost-effective for low to medium volume productions, prototyping, and custom parts because it avoids mold costs and allows quick changes in design.