Understanding and appropriately setting injection pressures is crucial in the field of injection molding. The injection pressure plays a significant role in achieving optimal part quality, dimensional accuracy, and material flow within the mold. Different plastic materials require specific injection pressure ranges based on their unique properties and processing requirements. In this post, we will explore the concept of injection pressures, learn different injection molding pressures, discuss how to set and monitor them effectively and provide an overview of injection pressure ranges for various plastic materials.

Understanding Injection Pressure In Injection Molding

Injection pressure in injection molding refers to the force applied to the molten plastic as it is injected into the mold cavity. It is typically measured in pounds per square inch (psi) or megapascals (MPa). It plays a critical role in achieving proper filling, packing, and material flow, ultimately affecting part quality, dimensional accuracy, and process efficiency. Proper understanding and control of injection pressure are essential for successful injection molding operations. Optimizing the injection molding pressure involves considering the material’s melt flow properties, mold design, gate size, and process parameters like injection speed and packing time. It requires a balance between achieving complete mold filling and avoiding potential defects.

Classification of Plastic Injection Molding Pressures

Plastic injection molding pressures can be classified into different types based on their application and purpose. Here are three common classifications of plastic injection molding pressures:

1. Injection Pressure:

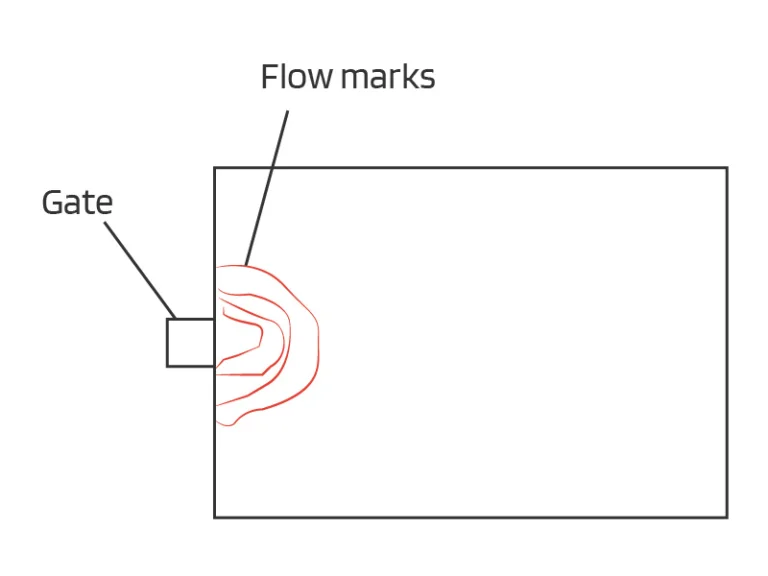

- Injection Pressure: This refers to the pressure applied to the molten plastic material during the injection phase. It determines the speed and efficiency of filling the mold cavity.

- Holding Pressure: Also known as packing pressure, it is applied after mold filling to compensate for material shrinkage and maintain part dimensions.

2. Clamping Pressure:

- Clamping Pressure: This is the force exerted by the clamping unit to hold the mold closed during the injection molding process. It ensures proper sealing and prevents flash or part ejection issues.

- Tonnage: Clamping pressure is often measured in terms of tonnage, indicating the force required to keep the mold closed. Higher tonnage is needed for larger and more complex molds.

3. Back Pressure:

- Back Pressure: It is the resistance applied to the injection screw during the plasticizing phase. Back pressure helps maintain melt homogeneity, remove air bubbles, and improve melt quality.

- Screw Recovery Pressure: This pressure is applied when the injection screw retracts or recovers after injecting molten plastic into the mold cavity. It helps prevent material leakage and ensures consistent melt volume.

These classifications reflect different aspects of the injection molding process and help in optimizing parameters for specific requirements. Proper control and adjustment of these pressure types are crucial for achieving successful and high-quality plastic injection molding.

Calculating Injection Pressure

Calculating injection pressure in injection molding involves considering various factors such as material properties, part design, machine specifications, and process conditions. The injection pressure is typically determined based on the following factors:

How to Calculate Injection Pressure?

- Part Design: The complexity, size, and shape of the part influence the required injection pressure. Parts with thin walls or intricate geometries may require higher pressures to ensure proper filling and adequate material flow.

- Material Properties: Each plastic material has different viscosity and flow characteristics. The melt flow rate (MFR) and melt density of the material are essential parameters for determining the injection pressure.

- Injection Speed: The rate at which the material is injected into the mold affects the required pressure. Higher injection speeds generally require higher pressure to overcome resistance and fill the mold efficiently.

- Mold Design: The mold design, including the runner system and gate size, influences the flow of molten plastic. Properly designed molds can help optimize the injection pressure and ensure uniform filling of the mold cavities.

- Machine Specifications: Injection molding machines have specific maximum injection pressures they can generate. The machine’s maximum injection pressure should be considered to ensure it can deliver the required pressure for the specific application.

Calculate Methods

To calculate the injection pressure, various methods can be used, such as:

Injection Pressure Estimation:

The injection pressure can be estimated using a simple formula: P = K*Q/A, where P is the injection pressure, K is a process-dependent constant, Q is the maximum shot volume, and A is the projected area of the part.

Mold Filling Simulation:

Advanced software tools, such as Moldflow, allow for computer-aided mold filling simulations. These simulations consider the part geometry, material properties, machine settings, and process conditions to predict the required injection pressure.

Material Data:

Obtain the material data sheet for the specific resin being used. It provides information on the melt flow rate (MFR), melt density, and other material properties relevant to injection molding.

Pressure Maintenance in Injection Molding

Pressure maintenance is an important aspect of injection molding. It refers to the ability of the injection molding machine to maintain the required injection pressure during the entire injection cycle. Pressure maintenance ensures consistent filling of the mold cavity and helps achieve quality and dimensional accuracy in the final molded product.

Proper pressure maintenance involves factors such as machine design, hydraulic system performance, and process optimization. By adjusting and monitoring pressure maintenance effectively, you can achieve consistent and high-quality injection molding results.

Setting The Injection Pressure

Setting the injection pressure in the injection molding process is a critical parameter that affects the quality and consistency of the molded parts. There are several aspects that should be referred to.

Material Guidelines: Consult the material supplier’s specifications and guidelines to determine the recommended injection pressure range for the specific material being used.

Initial Trials: Start with a conservative injection pressure setting within the recommended range. Conduct initial trials while closely monitoring part quality and inspecting for any defects.

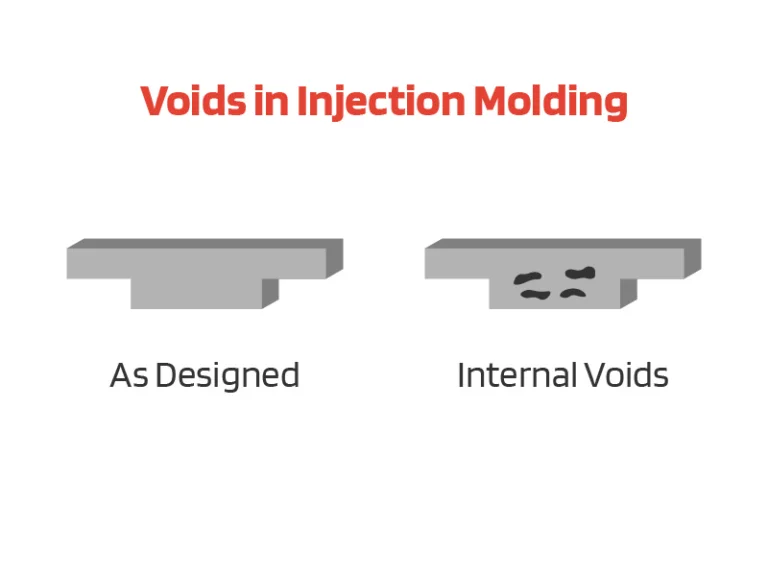

Evaluate Part Quality: Examine the molded parts for potential issues like short shots, sink marks, or warpage. Adjust the injection pressure incrementally to address any quality concerns and achieve optimal part filling.

Iterative Optimization: Fine-tune the injection pressure by making small adjustments and evaluating their impact on part quality and process stability. Aim for consistent part dimensions, surface finish, and overall quality.

Documentation and Monitoring: Maintain a record of the optimized injection pressure settings for future reference. Continuously monitor the process and make adjustments as needed to ensure consistent and high-quality production.

It’s important to note that the optimal injection pressure may vary depending on factors like part design, material properties, mold characteristics, and specific requirements. Regular monitoring, analysis, and adjustment are essential to achieve the best injection pressure for each molding application.

Injection Pressure for Different Plastic Material

The injection pressure for different plastic materials can vary based on their specific properties and processing requirements.

Here are some general guidelines for injection pressure ranges for commonly used plastic materials:

- Polypropylene (PP): Injection pressure range typically falls between 6000 and 18000 psi (41 to 124 MPa).

- Polyethylene (PE): Injection pressure range typically falls between 6000 and 18000 psi (41 to 124 MPa).

- Acrylonitrile Butadiene Styrene (ABS): Injection pressure range typically falls between 8000 and 18000 psi (55 to 124 MPa).

- Polystyrene (PS): Injection pressure range typically falls between 6000 and 15000 psi (41 to 103 MPa).

- Polyvinyl Chloride (PVC): Injection pressure range typically falls between 8000 and 16000 psi (55 to 110 MPa).

- Polyethylene Terephthalate (PET): The injection pressure range typically falls between 9000 and 16000 psi (62 to 110 MPa).

It’s important to note that these ranges are general guidelines, and the specific injection pressure required may vary depending on factors such as part design, wall thickness, melt temperature, mold complexity, and machine capability.

It is recommended to refer to the material supplier’s specifications and processing guidelines for more precise injection pressure recommendations for each specific material.

Additionally, conducting trial runs and fine-tuning the injection pressure based on the observed results is crucial for optimizing the process and achieving the desired part quality.

Conclusion

Properly setting and controlling injection pressures is essential for successful injection molding operations. The injection pressure directly influences the filling and packing phases, material flow, part quality, and overall process efficiency. By understanding the specific requirements of different plastic materials and considering factors such as part design, mold complexity, and machine capability, manufacturers can optimize injection pressure settings to achieve desired outcomes. Regular monitoring, adjustment, and fine-tuning of injection pressures throughout the production process enable consistent quality and help avoid issues like flashes, short shots, or warping. By mastering the art of managing injection pressures, manufacturers can enhance their productivity, minimize defects, and deliver high-quality plastic parts to meet customer expectations.