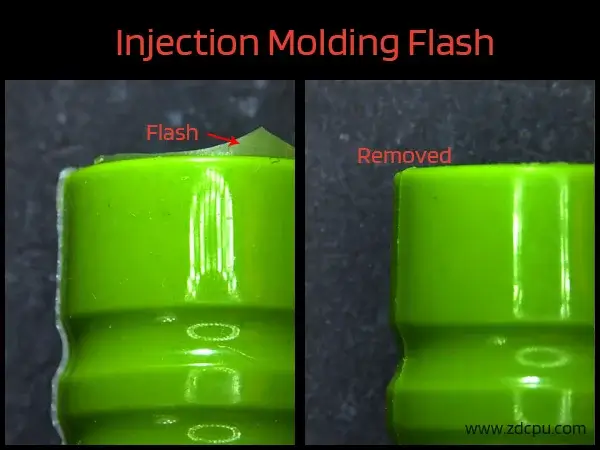

An injection molding flash occurs when molten plastic escapes the mold and solidifies. It is one of common injection molding defects. This molding defect will lower the quality of molded parts and potentially damage the mold, leading to increased costs. Understanding injection molding flash causes and solutions is crucial for efficient manufacturing. This article will explain flashes injection molding, exploring its causes, fixes, and prevention methods to optimize your projects.

What is Plastic Flash in Injection Molding?

Injection molding flash, often referred to excessive flash injection molding, is an unwanted protrusion on the final molded part. This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together. A thin layer of plastic is formed by excess molten plastic escapes and solidifies out of the mold cavity during the injection molding process. In the manufacturing process, the manufacturer should minimize or eliminate mold flash to improve molded parts quality and assembly.

Impact of Flash on Plastic Parts

Flash injection not only affects the appearance and quality of plastic parts but can also compromise their performance and service life. If left unaddressed, flash can expand, damage the mold, and cause permanent deformation. Flash around inserts or ejector pin holes may also hinder part ejection, making it essential to control flash during production.

Acceptance Criteria for Flash on Plastic Parts

While injection flash in molding is often unavoidable, it can be minimized and kept within acceptable limits. For high-precision parts, flash injection should not exceed 0.05 mm; for less demanding applications, it should be within 0.1 mm. Acceptance standards should be defined based on the part’s actual usage requirements.

What Causes Flash Plastic Injection Molding?

Parting Line Mismatches

When the two halves of the mold don’t match perfectly, it creates gaps for molten plastic to escape, leading to flash formation.

Improper Venting

Inadequate venting in the mold can trap air or molten plastic, causing excessive pressure that pushes plastic into areas where it shouldn’t be.

Low Clamping Pressure

Inadequate clamping pressure can allow the mold to slightly separate during the injection process, leading plastic to escape and form a moulding flash.

Low Viscosity

Low-viscosity plastics are easier to leak at mold parting lines, increasing the risk of flash.

Uneven Molten Plastic Flow

Inconsistent plastic flow due to issues like temperature variations can lead to flash at the boundaries where flow disparities occur.

Overfilling the Mold

Injecting too much material into the mold cavity can cause excessive pressure, leading to flash as plastic seeks escape routes.

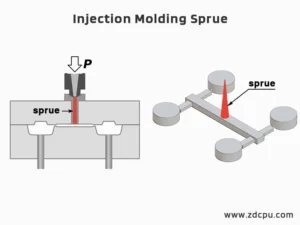

Sprue Bushing Issues

Problems with the sprue bushing, such as wear or misalignment, can contribute to flash by allowing the plastic to seep through.

How to Remove Flash Molding Defect from Injection Parts?

When injection molding excess flash occurs, it’s essential to eliminate flash promptly to ensure the final product meets quality standards. The removal of flash, also known as de-flashing, can be achieved through several post-processing techniques, the common three flash removal methods are trimming, grinding, and deburring.

Trimming

Manual removal of flash using knives or shears; precise but time-consuming, best for small production runs.

Grinding

Uses machines to remove flash quickly; ideal for high volumes but requires dust control.

Deburring

Smooths sharp or rough edges left by flash using abrasives or brushes to improve surface finish.

How to Prevent Injection Molding Flash?

Optimize Design for Manufacturability:

Begin the prevention process with a well-design. Design parts and molds with manufacturability in mind, and consider factors like parting lines and potential flash areas.

Slow Down the Injection Rate:

Controlling the injection rate can help reduce the chances of flash formation. Slower injection rates allow for better control of the molten plastic flow, minimizing the risk of escaping material.

Specify a Flash-Free Mold:

Invest in molds designed to minimize or eliminate flash. Molds with tight parting line clearances and proper alignment can significantly reduce flash issues.

Proper Mold Cleaning:

Keep molds clean and free of any residue or contaminants. Proper mold cleaning ensures that there is no residue that could result in a flash.

Proper Mold Maintenance and Process Improvements:

Regular mold maintenance is crucial for preventing flash. Ensure that mold components are in good condition, and implement process improvements to optimize molding conditions.

Proper Clamping Pressure in the Packing Phase:

Adequate clamping pressure during the packing phase of injection molding is important. Proper clamping pressure helps keep the mold closed tightly, reducing the possibility of flash formation.

Injection Molding Service

Other Injection Molding Defects

Below are some common plastic molding defects that may occur in injection molding. Each defect has its unique causes and prevention measures.

- Weld Lines: Weld lines occur when two flow fronts meet and fuse during the injection process. They can weaken the structural integrity of the part, affecting its performance.

- Sink Marks: Sink marks appear as depressions or dimples on the surface of the molded part, often caused by variations in wall thickness or cooling rates.

- Short Shots: Short shots happen when the molten plastic doesn’t completely fill the mold cavity, resulting in incomplete parts. This defect can be due to factors like inadequate material volume or excessive cooling.

- Splay: Splay is the appearance of white streaks or lines on the surface of molded parts, typically caused by moisture or contaminants in the plastic resin.

- Warpage: Warping occurs when the part deforms or twists after cooling, usually due to uneven cooling rates or improper ejection from the mold.

- Burn Marks: Burn marks are discolored or charred areas on the part’s surface, often resulting from overheating or excessive residence time in the mold.

- Jetting: Jetting manifests as a streak or jet-like mark on the part, typically caused by high-speed plastic flow that doesn’t fill the mold cavity properly.

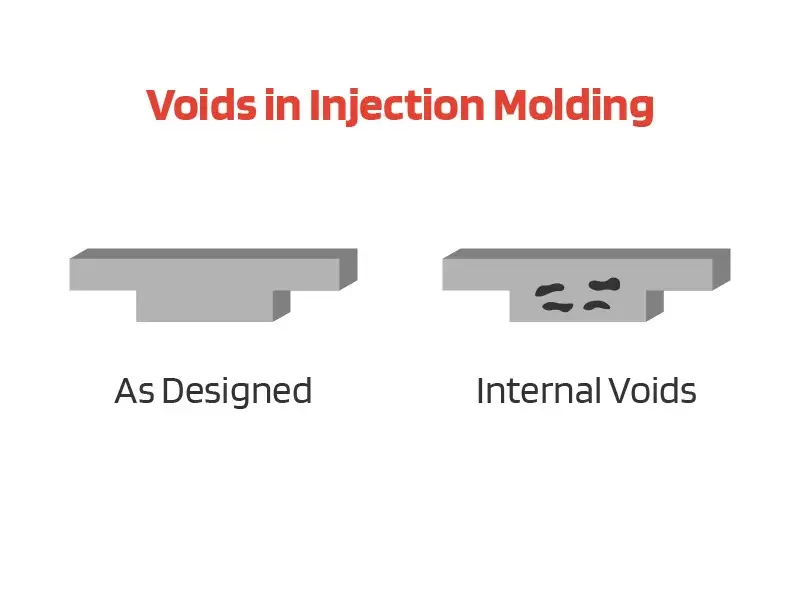

- Voids or Air Traps: Voids or air traps are pockets of trapped air within the part, which can lead to structural weaknesses or visual defects.

Conclusion With Plastic and Rubber Flash

Injection molding flash is a defect that impacts product quality and threatens molds. This article has addressed its causes, solutions, and preventive strategies. To solve this challenge, partnering with professional manufacturers who specialize in process optimization and mold design, is important. If you would like to learn more about plastic and rubber injection molding, welcome to contact Zhongde.

Related FAQs With Plastic Flash Injection

A burr forms after machining or cutting, while a flash appears along the mold parting line during molding.

Flash removal (deflashing) can be done manually, mechanically, or by cryogenic and trimming processes, depending on the precision and volume of production.

Rubber flash can reduce the visual quality and dimensional accuracy of the part. In precision assemblies, it may cause sealing or fitting issues.