Gate blush in injection molding is a prevalent issue in injection molding manufacturing. This article explores what gate blush injection molding is and how to prevent gate blush.

What is Gate Blush in Injection Molding?

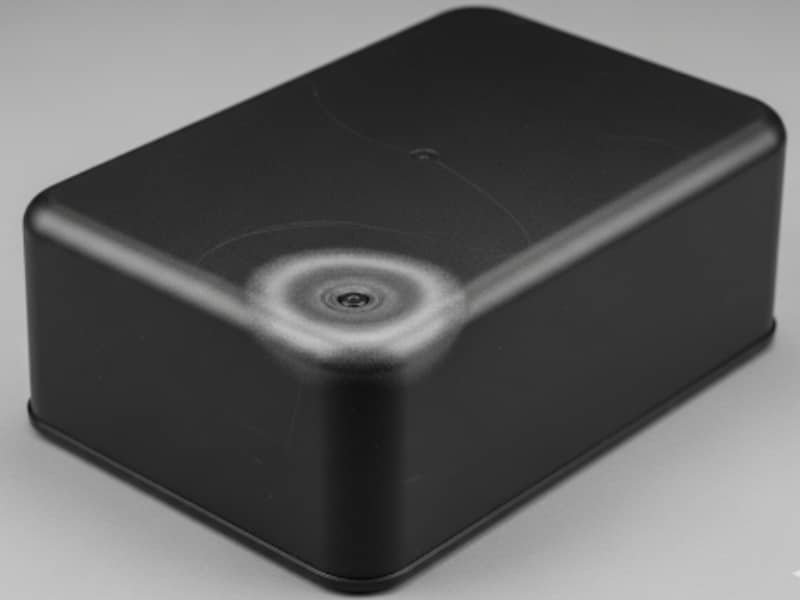

Gate blush is one of the defects in injection molding that typically appears near the gate area of injection-molded plastic parts. It manifests as a dull, cloudy, or frosted appearance around the gate where molten plastic enters the mold cavity. Sometimes, the gate blush is described as a white, hazy ring or frost-like bloom. This defect is most noticeable in transparent or light-colored materials.

Why Gate Blush Matters in Injection Molding?

The gate blush in injection molding directly impacts both the visual quality and functional performance of molded parts.

- Aesthetically, gate blush appears as a cloudy or hazy discoloration near the gate area of an injection-molded part. This defect spoils the visual appeal, especially on transparent or glossy surfaces, making the product look dull or uneven. It is an unwanted blemish that can affect customer perception of quality.

- Functionally, gate blush is caused by excessive shear stress and turbulent flow at the gate due to high injection speed, small or improper gate design, or incorrect processing temperatures. This can lead to internal stresses or weaker mechanical properties in the part, potentially reducing its durability and performance.

Causes of Gate Blush in Injection Molding

Understanding the causes of gate blush in injection molding is the first step toward effective prevention. This defect arises from a combination of factors. Below are the primary causes:

Material Sensitivity

Certain materials, such as ABS, PC, or TPOs, are more susceptible to gate blush due to their high viscosity or moisture content. Improperly dried materials exacerbate the issue by introducing bubbles or inconsistencies.

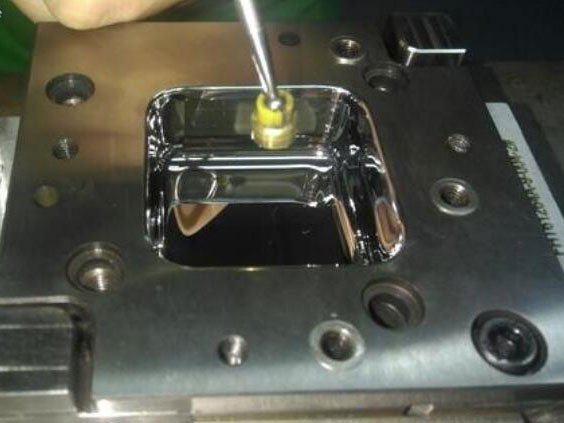

Small or Improper Gate Design

Gates that are too small or not suited to the material’s flow characteristics increase shear stress as molten plastic is forced through a restricted opening. This high shear creates localized overheating, resulting in gate blush.

Poor Gate Location

Placing gates in thin-walled areas causes premature hardening, preventing uniform filling of thicker sections and leading to surface defects.

Small Nozzle Diameter

A restrictive nozzle exacerbates flow resistance, amplifying shear stress and increasing the likelihood of gate blush in injection molding.

Inadequate Mold Venting

Trapped air or gases in the mold cavity disrupt material flow, creating imperfections like gate blush or burn marks.

High Injection Speed

Rapid injection speeds cause turbulent flow, especially at the gate, where the material experiences excessive shear and heat, leading to discoloration and surface imperfections.

Low Injection Pressure

Insufficient pressure can cause hesitation or uneven flow, allowing the material to cool prematurely and form a hazy appearance at the gate.

Improper Melt or Mold Temperatures

Temperatures outside the material’s recommended range—either too high or too low—disrupt smooth flow and solidification, contributing to gate blush.

Strategies to Prevent Gate Blush Injection Molding

Preventing gate blush in injection molding demands a multifaceted approach that optimizes every aspect of the molding process. Here are proven strategies:

Optimize Gate Design

Selecting the correct gate type, such as edge, pin, or submarine gates, and sizing it properly ensures smooth plastic flow. Increasing the gate size can lower shear rates, though it must be balanced with cycle time and cosmetic considerations.

Improve Gate Placement

Position gates in thicker-walled areas to promote even filling and prevent premature solidification in thin sections. Avoid placing gates near high-stress or visible areas of the part.

Enhance Mold Venting

Add vents covering approximately 30% of the mold perimeter to release trapped gases, reducing air entrapment and surface defects like gate blush.

Adjust Injection Parameters

Implement a multi-stage injection speed profile, starting with a slower speed (10–30 mm/s) to minimize turbulence and gradually increasing as the cavity fills. Maintain optimal injection pressure to ensure consistent flow without hesitation.

Adjust Mold and Melt Temperatures

Setting the mold temperature to an optimal level for the specific polymer reduces shear-related erosion at the gate. For materials sensitive to temperature, slight adjustments—either raising or lowering—can prevent early solidification or excessive flow stresses. Melt temperature should be within the recommended range to maintain good flowability without degrading the resin.

Enhance Nozzle and Runner Systems

Use a nozzle diameter equal to or slightly smaller than the sprue bushing to minimize flow restrictions. Incorporate cold slug wells in the runner system to trap colder material, ensuring uniform flow into the cavity.

Material Preparation

Thoroughly dry moisture-sensitive materials to eliminate bubbles or inconsistencies that contribute to gate blush. Select resins with flow properties suited to the mold design, such as low-viscosity grades for intricate parts.

Simulation and Testing

Leverage mold flow analysis software, like Moldflow, to simulate material flow and identify potential gate blush risks before production. Conduct trial runs to fine-tune parameters and validate mold performance.

Zhongde’s Professional Solutions for Gate Blush In Injection Molding

At Zhongde, we specialize in solving complex injection molding challenges such as gate blush through professional mold design optimization, precise process tuning, and strict quality inspection. With our proven expertise, we deliver reliable solutions that help our clients achieve both performance and aesthetics. If you are looking for a trusted partner in injection molding, contact us today to discuss your project needs and explore our custom injection molding service.

FAQ

No, gate blush and flow marks are different. Gate blush is a cloudy or frosted discoloration around the gate area, caused by high shear stress or improper flow. Flow marks are wavy lines or streaks across the part’s surface, often due to uneven cooling or material flow.

All, The hazy or frosted look is a cosmetic defect, but it can indicate a weakened molecular structure from excessive shear or improper flow, reducing the part’s mechanical strength and durability. So, gate blush can impact both the look and, to some extent, the structural integrity of the part.