Fillets, or rounded transitions between surfaces, allow molded parts to distribute stress more evenly, enhance structural integrity, and improve design for manufacturability. Properly designed corners reduce the likelihood of defects, facilitate material flow during molding, and improve the durability of both functional and aesthetic features. In plastic part design, the use of fillet radius design is critical.

What are Sharp Corners?

A sharp corner is a sharp, shallow angle in a part or mold, typically occurring at junctions or within cavities. While designed to achieve precise geometry and positioning, sharp corners can become stress concentration points during manufacturing and use, potentially leading to material cracking or mold wear. Therefore, sharp corners are often rounded or chamfered to improve flow, reduce stress, facilitate demolding, and increase overall part strength and life.

How to Design Correct Corner Radii?

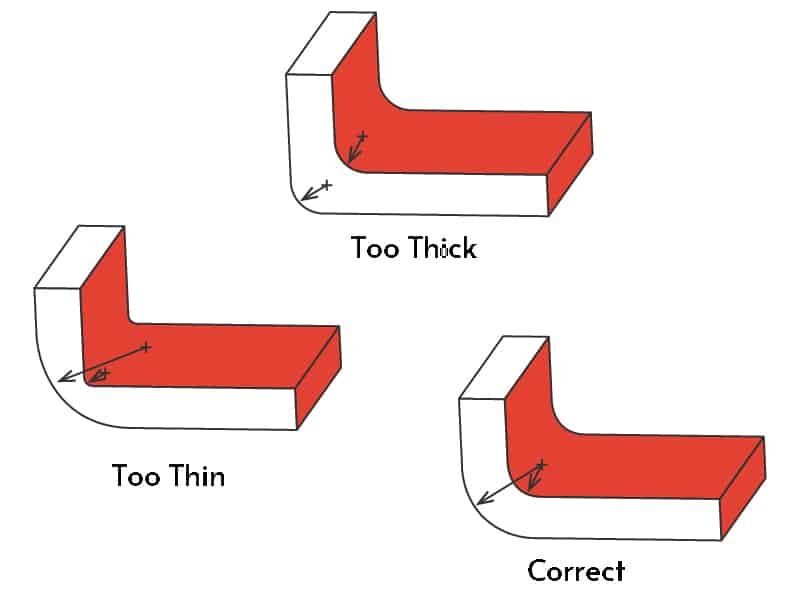

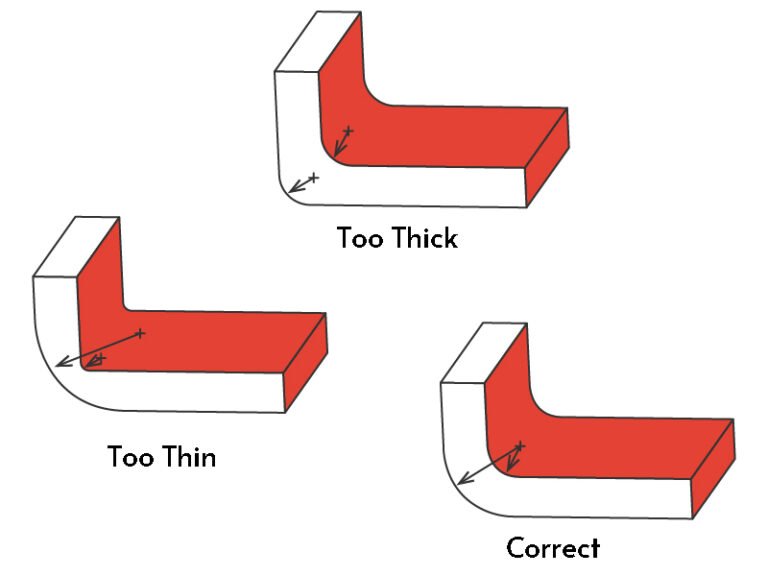

Internal fillets require a minimum radius of 0.5 times the adjacent wall thickness. External corners need 1.5 times the wall thickness to avoid thickening. Combine radii with draft angles for smooth flow.

Material selection influences radius size. Poor flow materials require larger radii to prevent short shots. Flexible materials allow smaller adjustments.

For geometry, avoid local thickening that causes sink marks; use ribs with their own rounded corners for reinforcement. When multiple intersecting walls are present, maintaining consistent fillet radius across all corners simplifies manufacturing and reduces the likelihood of weak points.

Learn more about fillet and fillet and chamfer.

Plastic Part Corner Design Principles

When designing plastic parts, sharp corners, right angles, or notches should be avoided at the junctions between walls, along the flow path of the molten plastic, and at the connections between walls and ribs, snaps, or posts. These features should be replaced with fillets, following the fillet design principles for plastic parts.

Fillets are designed to prevent stress concentration at sharp corners. Due to variations in the shape and cross-section of plastic parts, the flow of molten plastic changes abruptly at sharp corners during injection molding, generating high stresses that tend to remain in these areas.

Stress concentration is a major cause of failure in plastic parts under load. The stress distribution at sharp corners and fillets is shown in the figure below. Doesn’t it look like it could break easily?

CNC Machined Corner Radius Notes

When machining parts with CNC, the size of the corner radius directly impacts both machining efficiency and part performance, and different materials react differently. For hard materials like stainless steel or titanium, machining with small radii increases tool load, leading to higher cutting forces and significantly shortened tool life. Aluminum and other softer materials are relatively more tolerant of small radii, but even so, a properly enlarged radius can still help improve machining speed and stability.

In addition to material hardness, surface finish is also a key factor in determining radius selection. Certain materials can achieve better surface finishes with larger tools and higher cutting speeds, while forcing a too-small radius can negatively impact overall part quality. When machining sharp corners in composite or layered parts, special consideration must be given to the layer orientation, otherwise precision deviations or cutting defects are likely to occur.

While rounded corners are a preferred method for machining and design, sharp corners or small radii are unavoidable in some special scenarios. These functional requirements necessitate small radii or sharp corners and should be clearly defined during the design phase. For example:

- Small radii along machining paths allow the tool to access narrow or complex areas.

- Small radii in critical areas can reduce stress concentrations. In terms of heat and flow, a small radius improves melt or fluid flow and reduces defects.

- A small radius on moving parts prevents interference and ensures smooth movement.

- In terms of surface function, a small radius facilitates coating, plating, or friction surface treatment.

Injection-Molded Parts Corner Radius Notes

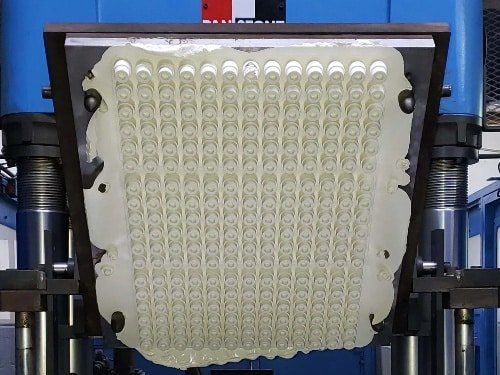

In injection molded part design, sharp and right angles can easily lead to stress concentration, uneven melt flow, and difficulty in demolding. When designing, pay attention to the following details:

- Wall-to-wall intersections should be rounded as much as possible to reduce stress, especially where thick walls meet thin walls.

- Corners along the melt flow direction should have smooth transitions to prevent melt washout and uneven filling.

- Gradual fillets are recommended at the joints between walls and reinforcements, supports, or clips to ensure structural strength while avoiding localized cracking.

- For thin-walled parts, the radius can be increased to improve melt flow, reduce porosity, and reduce warping.

The overall principle is to ensure smooth melt flow, even stress distribution, and facilitate demolding.

Handling Sharp Corners

Sharp corners are unavoidable for certain functional requirements, such as accommodating existing hardware interfaces, fluid passages, or assembling moving parts. In these cases, the size and location of sharp corners should be clearly defined, and appropriate materials and demolding methods should be selected. If necessary, local chamfers or auxiliary demolding structures can be added to reduce stress concentrations. Furthermore, the functional reasons for sharp corners should be documented during the design review phase to ensure process feasibility and part quality.

Zhongde is Your Design Guidance Expert

Corner design challenges find solutions with Zhongde. We offer customized design for manufacturability support and optimized radii for durable parts. Contact us for expert guidance on fillet radius standards and manufacturing.