What Is Core and Cavity in Injection Molding?

In customized injection molding, the core and cavity are used to create the desired shape of the molded part. When the mold closes, the core and cavity come together to create the mold cavity, which is then filled with molten plastic to form the final part shape. The core and cavity must be precisely designed and machined to ensure accurate part replication and optimal molding conditions.

Cavity in Injection Molding

The cavity is the stationary part of the mold and forms the outer surface of the molded part. It determines the shape, texture, and appearance of the final product. The cavity is responsible for creating the desired aesthetics and dimensional accuracy of the part.Core in Injection Molding

The core is the movable component that shapes the internal features of the part. It defines the intricate details, such as holes, recesses, and internal contours. The core moves within the mold to create the desired shape and geometry of the part’s interior.Core and Cavity Manufacturing Process

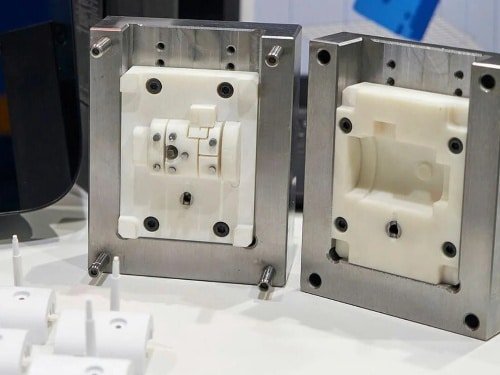

The manufacturing of mold cores and cavities follows a structured process to ensure precision and durability. It typically begins with material selection and rough machining, followed by CNC milling or EDM for detailed shaping. After heat treatment, the cores and cavities undergo grinding, polishing, and surface texturing according to design requirements. Once finished, they are assembled and fitted into the mold base to guarantee proper alignment. The process concludes with trial molding, where the mold is tested to verify dimensional accuracy, surface quality, and overall performance before mass production.The Importance of Core and Cavity in Injection Molding

The importance of core and cavity in injection molding can be summarized as follows:- Shape and Accuracy: The core and cavity define the shape and dimensions of the molded part. They are responsible for creating the desired features, details, and surface finish of the final product. Precise and well-designed core and cavity ensure accurate replication of the desired part geometry.

- Mold Functionality: The core and cavity play a critical role in the overall functionality of the mold. They enable the proper flow and distribution of the molten plastic material, ensuring consistent filling of the mold cavity. Properly designed and machined core and cavity allow for efficient and effective mold operation.

- Tooling Durability: The core and cavity experience high levels of stress and thermal cycles during the injection molding process. Therefore, they need to be made from durable and wear-resistant materials to withstand the demands of repeated molding cycles. Proper maintenance and quality construction of the core and cavity contribute to the longevity of the mold. View other ways to expand mold lifespan in this post.

- Cooling and Ejection: The core and cavity also contribute to the cooling and ejection processes. They incorporate cooling channels to dissipate heat from the molten plastic, aiding in solidification and cycle time optimization. Additionally, the cavity contains the ejection system, which helps remove the molded part from the mold after the cooling process.

Principle of Injection Molding Process

Types of Mold Cavities and Cores

In injection molds, there are many types of cavities, and cores can be categorized. There are some main types as bellow

1. Fixed Cavities and Cores:

Standard Cavities and Cores: These are the primary components of the mold that define the shape and features of the molded part. They are typically machined from hardened steel and remain fixed in the mold throughout the production process.

Simple Cavity/Core: This type of cavity and core is used for producing parts with straightforward shapes and minimal internal features. It consists of a single cavity and core component.

Multi-Cavity/Core: In this configuration, multiple cavities and cores are arranged within the mold to enable the simultaneous production of multiple parts in each molding cycle. It increases production efficiency and reduces cycle time.

2. Interchangeable Cavity/Core:

Interchangeable Cavity/Core: Interchangeable cavities and cores allow for flexibility in producing different parts using the same mold base. They can be replaced or swapped out to accommodate various part designs.

Replaceable Cavities and Cores: These are cavities and cores that can be easily replaced or interchanged in the mold. They are used when different part variations or designs need to be produced using the same mold base.

Sliding Cavities and Cores: Sliding cavities and cores have the ability to move or slide within the mold to create complex part features, such as side holes or threads. They are often used for producing parts with internal threads, sliding mechanisms, or other intricate features.

Insert Cavities and Cores: Insert molding involves placing pre-formed inserts or components into the mold, and the cavities and cores are designed to securely hold and encapsulate these inserts during the molding process.

3. Collapsible Core:

This type of core is used for producing parts with intricate internal features or threads. It allows for the creation of hollow or collapsible sections within the molded part.

4. Unscrewing Cavity/Core:

Unscrewing cavities and cores are utilized for producing threaded or screw-type parts. They can rotate or unscrew to release the threaded part from the mold.

The specific types of cavities and cores within each category can vary depending on the complexity of the part design and the specific requirements of the injection molding process. The choice of cavity and core types is determined by factors such as part geometry, parting line considerations, material flow, and ease of mold assembly and disassembly.

Our Mold & Tooling Service

How to Distinguish the Core and Cavity in Injection Molding?

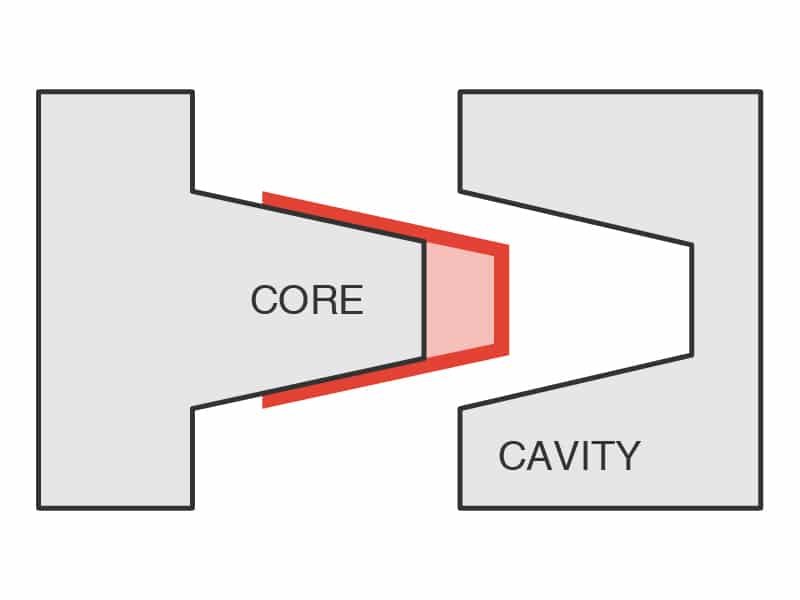

In injection molding, the terms “core” and “cavity” refer to two complementary injection mold components. While they work together to form a complete product, they can be distinguished through their appearance, structure, position, and function.

1. General Appearance

The core typically projects from the mold and forms the internal surfaces of the part, including holes, recesses, or inner walls. It is often seen as a solid, raised, or protruding feature.

The cavity, on the other hand, is the hollow portion of the mold that shapes the external surface of the product—its skin or outer contour.

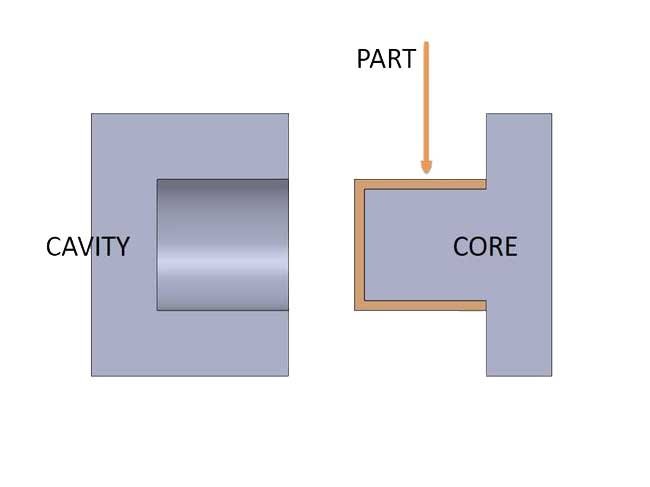

2. Position and Ejection

The core is typically located on the moving half of the mold. During mold opening, the molded part often sticks to the core and is then pushed out by the ejection system.

The cavity is generally part of the fixed half of the mold and remains in place while defining the product’s outside shape.

3. Structural Features

Core: Built solid and robust to withstand molding pressure. It often integrates cooling channels, ejector pins, or inserts to manage heat and part removal.

Cavity: Designed with more intricate details to capture the fine appearance and external geometry of the product.

4. Shape and Boundary

The core is usually convex (male mold), extending into the cavity to create inner features.

The cavity is concave (female mold), deeper and wider, shaping the product’s outer profile.

The dividing line between them is known as the parting line.

5. Identification and Markings

Cores and cavities are sometimes marked with numbers, letters, or identification codes. For example, part numbers, ejector pin marks, or engraved text may appear on the cavity side, while the core side often shows ejector-related details.

Design Tips for Successful Core and Cavity Production

- Material Selection: Core parts are commonly made from hardened steel, tool steel, or beryllium-copper alloys to withstand high injection pressures and provide good thermal conductivity, while cavities are usually made from durable tool steel or alloy steel to ensure wear resistance and a consistent surface finish.

- Shrinkage Allowance: Designers must account for material-specific shrinkage to ensure that the final part meets dimensional tolerances and maintains fine details.

- Parting Line Placement: The parting line should be positioned to allow smooth part release and minimize visible seams without interfering with functional features.

- Draft Angles: Appropriate tapers should be applied to vertical walls to enable the part to release cleanly from the mold and reduce the risk of sticking or deformation.

- Ejector Pin Placement: Ejector pins must be properly positioned and sized to remove parts efficiently without damage, working together with draft angles and the ejection system layout.

- Venting and Cooling: Venting should be provided to release trapped air, and cooling channels should be incorporated to regulate mold temperature, shorten cycle times, and maintain consistent part quality.

Conclusion

At Zhongde, we provide design and manufacturing services for mold cores and cavities, focusing on precision and reliability. By carefully considering the design, location, and function of each core and cavity, we help ensure consistent results and meet the required specifications in injection molding.