What is Low Volume Manufacturing?

Low volume manufacturing is producing limited quantities of goods, typically between 50 and 5,000 units. It is between one-off prototyping and large-scale mass production. Low volume production focus on flexibility over production scale. This manufacturing method allows businesses to test markets, validate designs, or cater to niche customer needs without committing to the high costs associated with mass production setups.

Benefits of Low Volume Manufacturing

The advantages of low volume manufacturing are manifold, making it a strategic choice for businesses seeking efficiency and adaptability. Here are the key benefits:

- Reduced Inventory Risk: By producing only what is needed, low production volume minimizes excess stock, cutting storage costs and reducing the risk of unsold inventory.

- Faster Market Response: Small volume production enables companies to bring products to market quickly, often within weeks, allowing them to capitalize on emerging trends or customer feedback.

- Customization and Personalization: Low volume production supports tailored solutions, enabling businesses to meet specific customer requirements.

- Design Iteration Flexibility: With prototyping and low volume production, manufacturers can refine designs based on real-world feedback without incurring significant retooling costs.

- Market Testing: Producing small batches allows companies to gauge market acceptance before scaling up, reducing the financial risk of launching unproven products.

Types of Low Volume Manufacturing

Low volume manufacturing encompasses a variety of production techniques, each suited to specific materials, precision levels, and applications. Below are the primary methods, along with their characteristics and use cases:

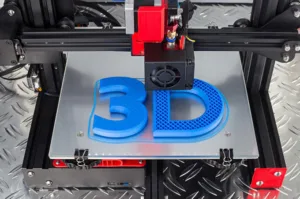

3D Printing

3D printing prototype service builds parts layer by layer, ideal for complex geometries and rapid prototyping. It’s widely used in small volume manufacturing for medical devices, aerospace components, and custom consumer goods due to its ability to produce intricate designs without expensive molds.

CNC Machining

A subtractive manufacturing method where parts are cut out of solid blocks using computer-controlled tools. CNC machining offers high precision, excellent surface finish, and is suitable for parts requiring tight tolerances. It is often used for small batch production of metal and plastic components.

Injection Molding

While traditionally associated with high-volume production, advancements in tooling have made custom injection molding service viable for low volume production. It’s suitable for consistent, high-quality plastic parts, such as enclosures for consumer electronics or medical equipment.

Sheet Metal Fabrication

This technique involves cutting and bending metal sheets to create structural components. It’s commonly used in small volume manufacturing for industrial equipment housings and architectural elements.

Vacuum Casting and Silicone Molding

These processes replicate master models to produce small batches of parts in flexible silicone molds. Commonly applied in product development phases, they offer relatively low cost and quick turnaround for polymer components.

Die Casting

This process involves forcing molten metal into a mold under high pressure, producing precise, durable parts with excellent surface finishes. It’s ideal for low volume production of metal components, such as automotive or machinery parts, where strength and consistency are critical.

Urethane Casting

Using silicone molds to cast polyurethane resins, this method is perfect for small volume production of parts that mimic injection-molded plastics. It’s widely used for prototypes, consumer products, and medical devices due to its cost-effectiveness and ability to replicate fine details.

Laser Cutting and Engraving

This technique uses a laser to cut or engrave materials like metal, plastic, or wood with high precision. It’s suitable for low volume manufacturing of custom panels, signage, or intricate components in industries like electronics and design.

Challenges of Low Volume Manufacturing

While low volume manufacturing offers significant advantages, it comes with its share of challenges that require careful management:

- Higher Per-Unit Costs: Unlike mass production, low production volume often results in higher costs per unit due to limited economies of scale.

- Process Optimization: Achieving consistent quality in small volume production requires frequent adjustments to machinery and processes, which can be time-consuming.

- Supply Chain Coordination: Sourcing materials for low volume production can be costly and complex, as suppliers may prioritize larger orders.

- Quality Consistency: Maintaining uniform quality across small batches is challenging, necessitating robust quality control measures.

Key Factors to Consider When Choosing Low Volume Production

When selecting low volume manufacturing for a project, companies should consider several critical factors:

- Product Complexity and Customization Needs: Choose manufacturing technologies that align with design requirements and material properties.

- Lead Time and Market Speed: Assess how quickly products must be delivered and select production methods accordingly.

- Cost Analysis: Balance tooling setup costs versus per-unit costs to optimize production efficiency.

- Volume Flexibility: Evaluate future scalability and potential volume changes.

- Quality Requirements: Ensure the chosen process can maintain desired quality and tolerances.

Comparing Low Volume and High Volume Manufacturing

The key differences between large volume and low volume manufacturing span cost structures, production timelines, flexibility, and innovation ability. The following table summarizes these distinctions:

| Aspect | Low Volume Manufacturing | High Volume Manufacturing |

|---|---|---|

| Cost | Higher per-unit cost, lower initial investment | Lower per-unit cost, high tooling investment |

| Production Cycle | Short, rapid response to market needs | Long, requires stable demand |

| Flexibility | High, easy to adjust designs and processes | Low, costly to modify designs |

| Design Iteration | Supports frequent updates, ideal for new products | Limited iteration, suited for mature products |

| Inventory | Low inventory holdings, production on demand | High inventory to meet mass demand |

| Applications | Custom products, market testing, prototyping | Standardized products, large-scale markets |

Start Low Volume Manufacturing with Zhongde

Zhongde offers professional low-volume manufacturing services tailored to meet diverse industry needs. By leveraging advanced technologies like 3D printing prototype service, china CNC machining service, and urethane casting, Zhongde ensures precision and efficiency in low production volume.