Injection molded magnets is a cutting-edge manufacturing technology that combines the power of traditional magnetism with the flexibility of modern manufacturing techniques. This article explores the composition, common materials, advantages, manufacturing process, and diverse applications.

What Are Injection Molded Magnets?

Injection molded magnets are permanent magnets composed primarily of two components: finely powdered magnetic materials blended homogeneously with a polymer or elastomer binder. This binder holds the magnetic powder together, providing the mixture with thermoplastic properties that allow it to be melted and injected into molds under pressure. The result is a magnetized component with precise dimensions and complex shapes.

Common Materials for Injection Molded Magnets

When crafting an injection molded magnet, the choice of materials influences everything from magnetic strength to environmental resilience. The most frequently used magnetic powders in injection molded magnets include Neodymium Iron Boron (NdFeB), Ferrite (iron oxide), and Samarium Cobalt (SmCo). The common polymers include nylon and PPS, etc. Each material offers distinct features:

- NdFeB are favored for their excellent magnetic flux density, offering high performance in compact forms. However, they may require protective coatings to combat corrosion in humid environments.

- Ferrite powders provide a cost-effective material. These materials boast great resistance to demagnetization, corrosion, and thermal stability up to 250°C.

- SmCo exhibits high thermal stability and retains magnetic properties even at high temperatures, making it perfect for environments with stringent thermal demands.

- Polymers like Nylon 6 (PA6), Nylon 12 (PA12), and Polyphenylene Sulfide (PPS) serve as common binders, selected for their mechanical strength, temperature resistance, and compatibility with magnetic powders.

Advantages of Injection Molded Magnets

The injection molded magnet offers a suite of benefits that distinguish it from traditional magnetic materials.

- Complex Geometries: The injection molding process permits the production of intricate shapes and detailed features that would be difficult or costly to achieve with other techniques.

- High Production Efficiency: Injection molding supports high-volume manufacturing with repeatable precision and short cycle times, reducing overall production costs.

- Tight Tolerances and Dimensional Consistency: Mold design and controlled processing ensure each magnet meets exact dimensional specifications and ensure seamless integration into complex assemblies, reducing post-processing needs.

- Uniform Magnetic Properties: Magnetic powders are evenly distributed within the binder, yielding consistent magnetic performance throughout the part.

- Multi-Material Integration: Techniques such as overmolding enable combining magnets with other plastics or metal components in a single manufacturing step, minimizing assembly efforts and expenses.

- Enhanced Mechanical Strength and Corrosion Resistance: The polymer content offers toughness and environmental durability without requiring additional coatings in most cases.

- Tailored Magnetic Performance: Whether isotropic or anisotropic, injection molded magnets support multipole magnetization in a single step, optimizing energy efficiency in motors or generators.

Manufacturing Process for Injection Molded Magnets

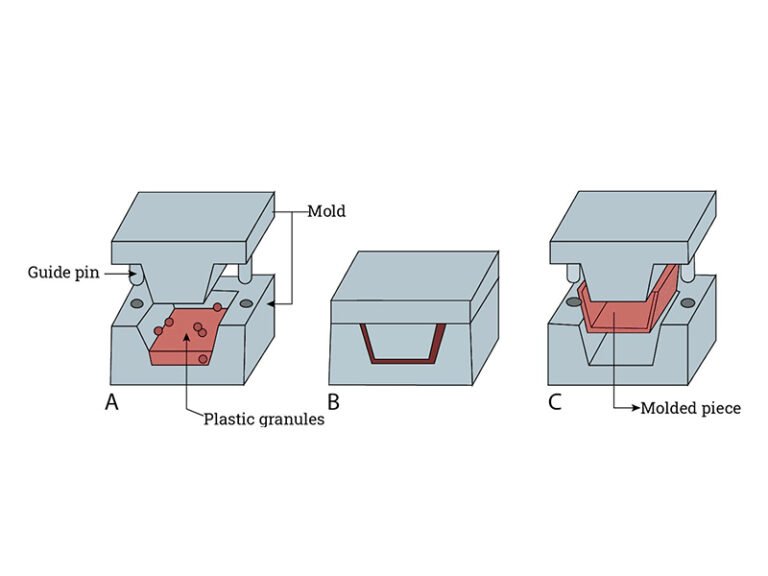

Producing an injection molded magnet involves streamlined steps.

Mold Design: Design precise molds accounting for the desired magnet shape, size, and internal features, leveraging custom insert molded magnet solutions to integrate magnets with complex assemblies, while ensuring thermal and mechanical robustness during processing.

Material Preparation: Magnetic powders and polymer binders are blended thoroughly to create a uniform thermoplastic compound, often granulated into pellets for ease of handling.

Melting and Injection: The compound pellets are heated to a molten state and injected into the mold cavity under high pressure to fill the shape.

Cooling and Solidification: The molten material cools within the mold, solidifying into the final magnet shape.

Magnetization: The solidified component is exposed to a strong magnetic field to align magnetic domains, achieving the desired magnetic strength and orientation.

Ejection: The solidified injection molded magnet is ejected from the mold.

Post-Processing (Optional): Steps like trimming, deburring, surface finishing, or coating may be conducted to improve aesthetics, functionality, or environmental resistance.

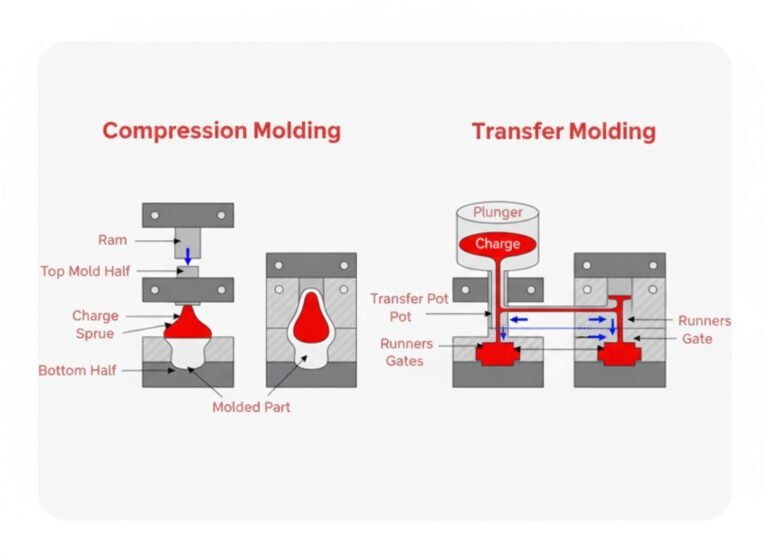

Comparison of Processing Methods for Magnets

The common magnet processing methods included injection molding, compression molding, and overmolding. Below is a detailed table outlining these differences:

| Method | Process Overview | Advantages |

|---|---|---|

| Injection Molding | Molten blend of magnetic powder and polymer binder injected into molds under pressure; cools to form complex shapes. | Enables intricate geometries, high-volume efficiency, tight tolerances (±0.05mm); supports overmolding for integrated assemblies. |

| Compression Molding | Magnetic powder coated with epoxy binder, then compacted under extreme pressure (e.g., 6 tonnes/cm²) and cured at 150-175°C in a die. | Achieves higher magnetic density (up to 85%); ideal for thin-walled or simple shapes; minimal post-processing needed. |

| Overmolding | A variant building on injection: Multiple materials layered onto a substrate in one mold, encapsulating components like sensors. | Reduces assembly steps by bonding magnets directly to plastics or metals; enhances durability and seals against environmental factors. |

Applications of Custom Injection Molded Magnets

Injection molded magnets find extensive application across multiple industries, with scalable manufacturing enabled by china injection molding services. They are widely used in aerospace for sensors and actuators, automotive electric motors and sensors, medical devices including MRI and surgical instruments, and consumer electronics such as speakers and hard drives.

Zhongde’s Custom Injection Molded Magnet Solutions

Zhongde offers professional custom insert molded magnet solutions, leveraging extensive experience in material selection, mold design, and manufacturing optimization. From prototype development to large-scale production, Zhongde supports every stage with technical expertise and injection molding services.