CNC turning transforms raw materials into precision components. This manufacturing process, rooted in the elegant interplay of rotating workpieces and cutting tools, delivers unparalleled accuracy and versatility. This guide delves into the principles, parameters, and diverse applications of the turning process, exploring its tools, materials, and operational nuances.

What Is CNC Turning?

CNC turning and CNC milling are two most common forms of CNC machining. In turning, the workpiece rotates while the cutting tool moves linearly. In milling, the cutting tool rotates and moves across a stationary or moving workpiece. Turning is ideal for producing round, tubular, or conical parts, while milling excels at flat, cubic, or complex 3D geometries.

The Principle Behind CNC Turning

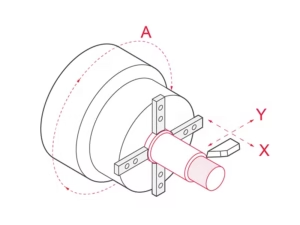

CNC turning is a precision machining process in which a workpiece is rotated while a cutting tool removes material to create the desired shape. The core principle involves the workpiece being held and spun by a chuck mounted on a spindle, which provides the primary rotary motion around the Z-axis. Meanwhile, the cutting tool performs a secondary motion—usually linear feed movements along the X and Z axes—to progressively shape the part’s external or internal surfaces.

CNC Turning Parameters

Common CNC turning parameters include:

- Spindle Speed (RPM): Measured in revolutions per minute (RPM), this determines how fast the workpiece rotates. Softer materials like aluminum thrive at higher speeds, while tougher metals like stainless steel require slower, steadier rates to prevent tool wear.

- Feed Rate: The speed at which the tool advances along the workpiece, typically in millimeters per revolution. A balanced feed rate ensures a smooth surface finish without overloading the tool.

- Cutting Depth: The thickness of material removed in a single pass. Shallow cuts enhance precision, while deeper cuts boost efficiency but risk tool damage.

- Cutting Tool Geometry: The shape and angle of the cutting tool, tailored to the material and desired outcome.

- Coolant Use: Application of cutting fluids to reduce heat and friction, prolonging tool life and improving surface quality.

Step-by-Step Operation of CNC Turning

Step by step CNC turning process as bellow:

1. Designing the Part: The process begins with creating a detailed 3D model of the part using CAD software, specifying dimensions, tolerances, and material.

2. Generating the CNC Program: The CAD model is converted into G-code via CAM software, translating the design into machine-readable instructions.

3. Machine Setup: The workpiece is mounted in the lathe’s chuck or collet, ensuring secure clamping to withstand high-speed rotation.

4. Executing the Turning Process: The machine spins the workpiece while the cutting tool moves according to the program, removing material to form the part.

5. Post-Processing: After machining, the part may undergo finishing operations such as deburring, polishing, or inspection to ensure quality.

6. Inspection: Once complete, the part is measured using precision tools like calipers or micrometers to verify dimensions and surface quality.

Types of Turning Operations

The versatility of CNC turning lies in its array of operations, each tailored to specific manufacturing needs. Key types include:

Straight Turning: The most common operation, where the cutting tool moves parallel to the axis of rotation, reducing the diameter uniformly, creating smooth, cylindrical surfaces ideal for shafts or rods.

Facing: Cutting a flat surface perpendicular to the workpiece’s axis, usually at the end of the part. Flattens the workpiece’s end, producing a smooth, perpendicular surface for subsequent machining.

Taper Turning: Producing conical shapes by moving the tool at an angle to the axis, common in components like tool handles.

Profiling: Shapes complex, non-linear contours, enabling intricate designs for parts like turbine blades or decorative fittings.

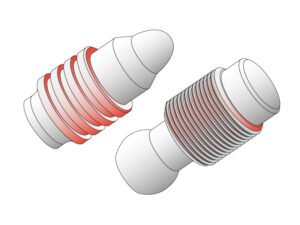

Threading: Cutting helical grooves on the external or internal surface to form threads and create screws or bolts, requiring precise tool movements to ensure thread accuracy.

Grooving: Creating narrow channels or grooves on the workpiece, often used for O-ring seats or decorative features.

Boring: Boring enlarges and finishes an existing hole in a workpiece to achieve greater accuracy and surface finish. It is often used to correct holes that are out of round or to increase their diameter with precision.

Drilling: Drilling create cylindrical holes along the axis of a rotating workpiece. The drill bit is fed axially into the workpiece to form the hole.

Knurling: Knurling produces a textured pattern, typically diamond-shaped, on the surface of a workpiece to improve grip. This operation is often applied to handles, knobs, or any part where enhanced friction is desired.

Parting (Cut-off): Parting, or cutting-off, separates a finished part from the remaining stock material. The cutting tool moves radially into the workpiece until it completely severs the part.

Tools and Equipment in CNC Turning

The turning manufacturing process relies on a suite of specialized tools and equipment, each integral to achieving high-quality results.

CNC Turning Equipment

- 2-Axis Lathes: Basic models suited for simple cylindrical parts, offering straightforward operation.

- Multi-Axis Lathes: Advanced systems with additional axes for complex geometries, enabling simultaneous turning and milling.

- Swiss-Type Lathes: Designed for small, high-precision parts, ideal for medical or watchmaking applications.

- Turret Lathes: Equipped with tool turrets for rapid tool changes, enhancing efficiency in high-volume production. Manual Lathes: Operated by hand, suitable for prototyping and simple jobs.

- CNC Lathes: Computer-controlled for high precision and automation.

- Turning Centers: Advanced multi-axis machines capable of both turning and milling operations.

Cutting Tools

- Single-Point Tools: Standard for most turning operations, made from carbide, HSS, or ceramics.

- Threading Tools: Thread tools are specialized cutting tools used to create internal or external screw threads on a workpiece. They can be single-point threading tools or threading inserts.

- Grooving Tools: Grooving tools create slots or grooves on a workpiece, which allows for intricate design patterns.

- Parting Tools: Parting tools cut off or separate a finished part from the remaining material.

- Drill Bits: Drill bits create holes of various sizes and depths in a workpiece. The flutes channel chips away, which prevents blockages and ensures a smooth drilling process.

- Boring Bars: Boring bars enlarge or smooth existing holes, ensuring precise diameters and finishes.

- Grinding Wheels: Grinding wheels are the primary tools for grinding and are made from abrasive materials like aluminum oxide or diamond. They come in various shapes and sizes to suit different applications, from surface grinding to cylindrical grinding.

Work holding Devices

- Chucks: Three- or four-jaw devices for gripping the workpiece.

- Collets: For smaller, high-precision parts.

- Faceplates and Mandrels: For irregular shapes.

Auxiliary Systems

- Coolant Delivery: Essential for heat dissipation and chip removal.

- Tool Turrets: Hold multiple tools for rapid, automated tool changes.

Common Materials in CNC Turning

The turning process accommodates a wide range of materials, each chosen for its unique properties and applications. These materials fall into two primary categories: metals and plastics.

CNC Turning Metals

Metals are the most used CNC turning materils. Different types of metals and alloys have different properties and applications. They are included aluminum alloys, stainless steel, steel, titanium alloys, brass and cooper, etc.

CNC Turning Plastics

CNC turning can also machine products from various rigid plastics. Such as ABS, Nylon, PEEK, Acrylic, etc.

Applications of CNC Turning

The CNC turning process is a versatility process various industries. Its ability to handle diverse materials and produce both custom one-offs and high-volume batches makes CNC turning indispensable.

CNC Turning in Manufacturing

- Rapid Prototyping: CNC turning excels in rapid prototyping, enabling manufacturers to create functional models swiftly and cost-effectively. The machining turning process produces complex components with precision, allowing engineers to test fit, form, and function. Quick iterations are possible, refining designs through real-world testing.

- Custom One-Off Productions: The process of turning shines in crafting bespoke parts tailored to unique needs. CNC turning delivers without reliance on slow OEM supply chains. In medical applications, custom implants or surgical tools are machined to match individual patient anatomies, enhancing outcomes.

- Batch Production: For high-volume manufacturing, CNC turning produces consistent, high-quality parts for final assemblies or larger systems. Industries like automotive and electronics rely on the turning manufacturing process to churn out threaded fasteners, bearing sleeves, and pins with tight tolerances.

Advantages and Disadvantages of CNC Turning

The CNC turning process offers a compelling array of benefits, though it comes with certain limitations.

Advantages of CNC Turning

High Precision and Accuracy: CNC turning machines are controlled by computer programs that automation eliminates human error, allowing for repeatability across large production runs and tight tolerances on complex parts.

Flexibility in Manufacturing: CNC turning centers can handle a wide variety of materials—including metals like steel, aluminum, titanium, and plastics—and accommodate different part sizes. It is suitable for prototyping, custom one-offs, and mass production.

Efficiency and Speed: Automation streamlines production, reducing labor costs and cycle times.

Capability to Produce Complex Shapes: CNC turning can produce a variety of features such as tapers, threads, grooves, and contours, enabling complex part geometries within its operational constraints.

Disadvantages of CNC Turning:

Initial Cost: CNC lathes and tooling require significant upfront investment, a barrier for small operations.

Material Waste: As a subtractive manufacturing process, CNC turning removes material from the workpiece, generating waste in the form of chips.

Material Limitations: Best suited for cylindrical parts, less effective for flat or irregular shapes compared to milling.

Skilled Labor: Operators must be trained in CNC programming and machine maintenance, adding to operational costs.

Conclusion

CNC turning is a versatile manufacturing method, It is an exemplifies precision and versatility. If you need CNC turned parts for your next project, Zhongde provides CNC turinging and milling services, welcome to contact with our experters.

FAQs of CNC Turning

Small parts with simple geometries may take minutes to complete, while larger or more intricate components can take several hours or even days. The time depends on various factors such as the complexity of the part, material type, tolerances required, machine setup, etc.

There are several types of CNC turning machines, categorized primarily based on the number of axes and the orientation of the spindle. The common CNC turning machines are 2-Axis CNC lathe, 3-Axis CNC lathe, 4-Axis CNC lathe, 5-Axis and 6-Axis CNC lathe.

A lathe is a simple turning machine for basic operations, while a CNC turning center is more advanced, offering automated control, multi-axis capabilities, and additional features like live tooling.