Acrylic molding offers various methods, including injection, extrusion, 3D and thermoforming, to suit different applications, PMMA 3D printing, also known as acrylic 3D printing, is popular for its unique blend of clarity, durability, and versatility. This article delves into the essentials of 3D printing with acrylic.

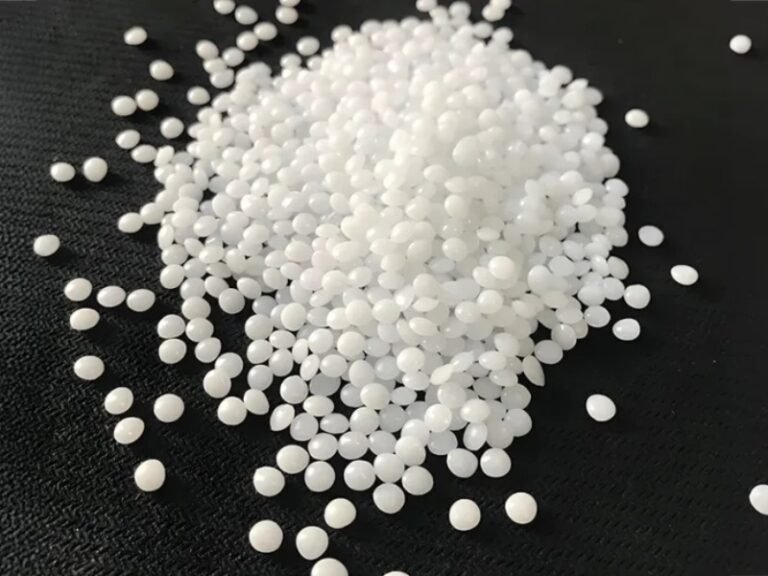

What is PMMA?

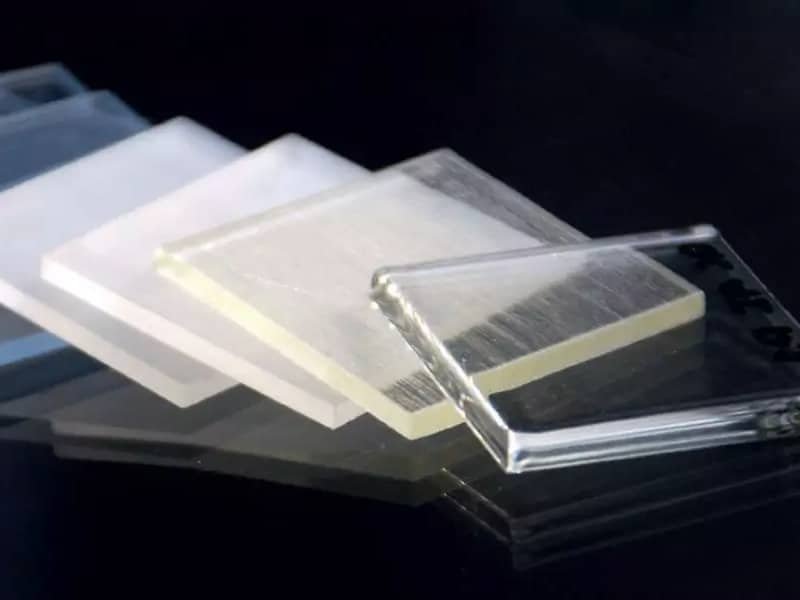

PMMA, or acrylic, is a thermoplastic celebrated for its glass-like transparency, boasting up to 92% light transmission. This makes it a top choice for acrylic 3D printing projects requiring optical clarity. Beyond aesthetics, PMMA offers impressive impact resistance, UV stability, and affordability compared to materials like polycarbonate. Its ability to withstand outdoor conditions without yellowing positions it as a go-to material for durable, long-lasting prints.

However, PMMA printing has some challenges. The material is brittle and can crack under heavy loads. It needs high printing temperatures (245–255°C), which can be hard on standard printers and use more energy. PMMA softens around 130°C, limiting its use in hot environments. It also releases fumes during printing, so good ventilation is necessary.

PMMA 3D Printing Service

How to Use PMMA for 3D Printing?

Mastering 3D printing with acrylic involves a structured approach to equipment setup, printer configuration, and post-processing. Below is a step-by-step guide to achieve high-quality PMMA prints:

Prepare Printer:

Successful PMMA 3D printing requires an enclosed FDM printer capable of reaching nozzle temperatures of 245–255°C and a heated bed of 100–120°C.

Configure Printer Settings:

Set the nozzle temperature to around 250°C, adjusting within the 245–255°C range. A bed temperature of 100–120°C enhances adhesion. Opt for a slow print speed (≤30 mm/s). The ideal layer height is 0.1–0.2 mm. Calibrate the extrusion multiplier (90–110%) using a test cube.

Enhance Bed Adhesion:

Apply a glue stick, specialized heat bed sheets, or adhesives like EasyFix to secure the print. Clean the build plate thoroughly to remove any oils or debris that could compromise adhesion.

Load and Print:

Load the filament into the extruder, import your 3D model into slicing software, and apply the configured settings. Monitor the first layer closely to ensure proper adhesion before letting the print run.

Post-Processing:

Allow the print to cool gradually inside the enclosure. Once cooled, remove the print carefully. For a polished, crystal-clear finish, sand and mechanically polish the surface.

What is The Applications of PMMA 3D Printing?

The unique properties of PMMA make it suitable for a variety of applications where transparency, UV resistance, and aesthetic quality are paramount. Common uses of PMMA 3D printed parts include:

Optical components: Lenses, light diffusers, and protective covers benefit from PMMA’s clarity and UV stability.

Lighting fixtures: Acrylic’s light transmission and resistance to yellowing under sunlight make it ideal for lampshades and light guides.

Automotive Industry: PMMA’s impact and light transmission make it suitable for instrument panels, light covers, and custom tooling.

Electronics: PMMA’s electrical insulation properties and transparency make it suitable for electronic device housings, display screens, and protective casings.

Medical Field: The biocompatibility and precision of PMMA 3D printing support applications in dental prosthetics, surgical guides, and custom medical devices. such as temporary crowns, orthodontic retainers, and impression trays.

Protective casings: Electronics and medical devices often use PMMA for transparent housings that need to be both sturdy and visually clear.

Prototyping: Designers use PMMA 3D printing to create transparent prototypes for visual inspection and functional testing.

Decorative and artistic pieces: The material’s glossy finish and ability to be polished make it popular for custom jewelry, awards, and display items.

Precautions for PMMA 3D Printing

While PMMA printing offers possibilities, it requires careful handling to avoid pitfalls. Key precautions include:

- Ventilation: PMMA emits fumes that can cause dizziness. Always print in a well-ventilated area or use a fume hood.

- Temperature Safety: The high printing temperatures (up to 255°C) pose burn risks. Allow the printer and print to cool fully before handling.

- Warping Prevention: An enclosed printer and consistent bed temperatures (100–120°C) are critical to prevent shrinkage and warping.

- Bed Adhesion: Test adhesion with small prints and use adhesives to ensure the print stays secure throughout the process.

- Post-Processing Care: Handle brittle PMMA prints gently to avoid cracks. Use mechanical polishing for a safe, professional finish.

- Material Quality: Opt for reliable filaments to minimize printing issues and achieve consistent results.

- Health Safety: Wear gloves and a mask during printing and post-processing to reduce exposure to fumes and sanding dust.

Conclusion with Acrylic 3D Printing

In conclusion, acrylic 3D printing (PMMA 3D) offers a compelling option for producing transparent, UV-resistant, and durable parts that meet demanding aesthetic and functional requirements. While it requires more careful handling and precise printing conditions compared to more common filaments, the results is highly useful across diverse industries.

Zhongde specializes in advanced PMMA 3D printing with expert process control and quality assurance, ensuring every part meets strict standards. As one of the reliable plastic manufacturers in china, Zhongde offers flexible solutions tailored to your project needs, from rapid prototyping to small and medium batch production.