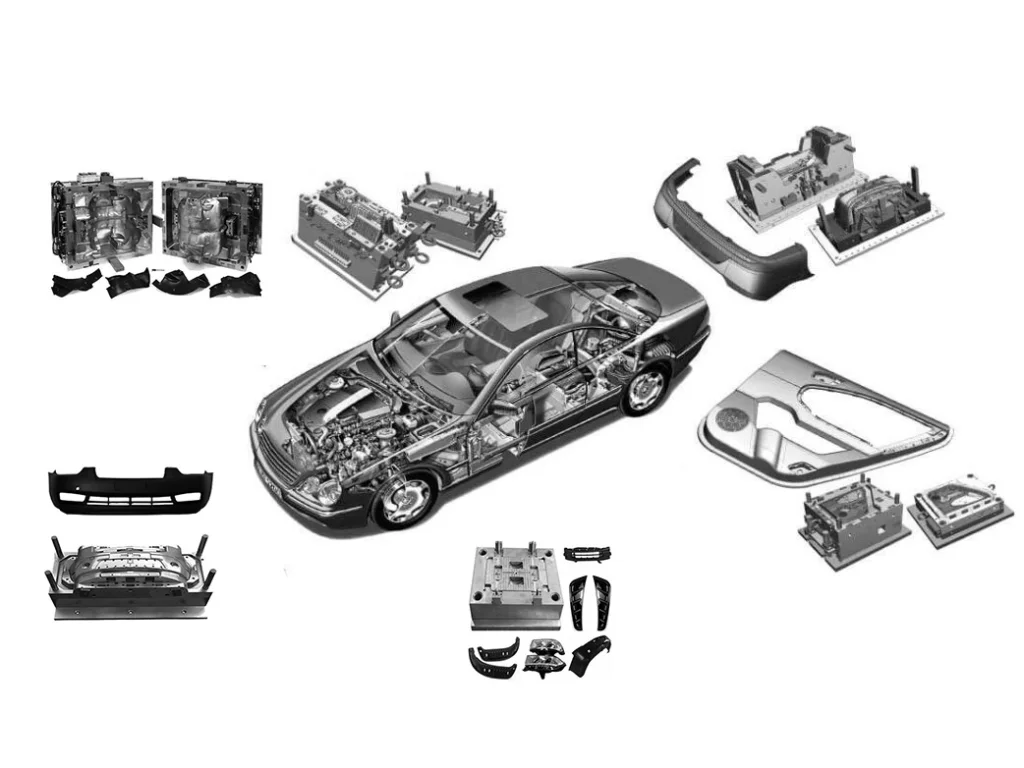

7 Automotive Injection Molding Benefits

Automotive injection molding is increasingly used in the automotive manufacturing industry because of automotive injection molding benefits. Automotive injection molding is famous for its efficiency, precision, and versatility. This process allows for the mass production of intricate components with consistent quality and tight tolerances, making it ideal for automotive applications. In this post, we will […]

7 Automotive Injection Molding Benefits Read More »