Mold flow analysis is an important tool in the manufacturing industry, especially in custom plastic injection molding. This analysis helps us to optimize the design of injection molds and plastic part design to achieve high-quality plastic parts. In this post, we will learn what is mold flow analysis, what are the benefits of mold flow analysis and how it improves the injection mold design.

What is Mold Flow Analysis?

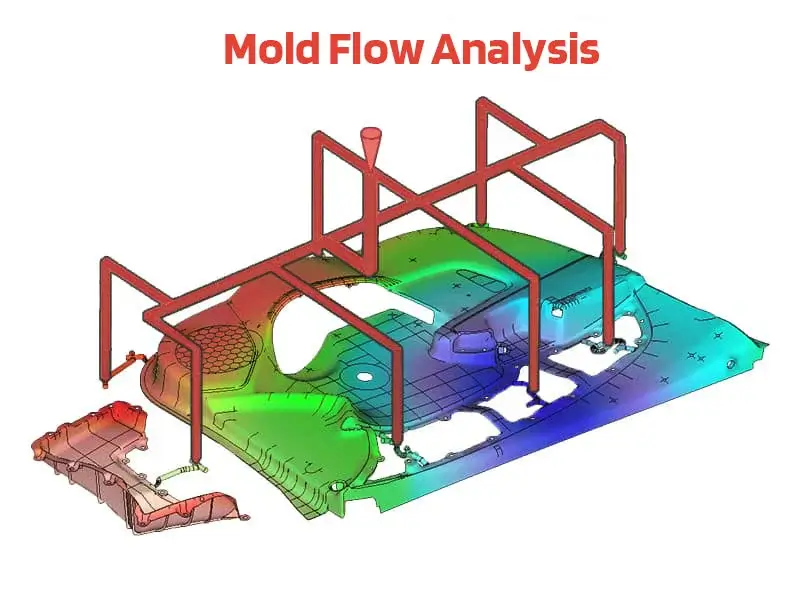

Mold flow analysis is a software simulation technique used in injection molding to predict and analyze how molten plastic material will flow and fill the mold cavity during the injection molding process. Common mold flow analysis software includes Moldflow, Moldex3D, Sigmasoft, ANSYS Polyflow, Cadmould, and SolidWorks Plastics.

During moldflow analysis, various parameters such as material properties, injection pressure, temperature, mold geometry, and gate locations are inputted into the software. The software then uses mathematical algorithms to predict how the molten plastic will flow, fill the cavity, cool, and solidify to form the final product.

The Purpose of Mould Flow Analysis

The primary goal of mold flow analysis is to identify potential manufacturing defects and optimize the design of the mold and part geometry before physical production begins. By simulating the injection molding process virtually, we can detect issues such as air traps, weld lines, sink marks, and short shots early in the design phase.

Differences in Resin Flow Behavior in Mold Flow Analysis

In mold flow analysis, different resins vary in viscosity, temperature sensitivity, and shear response. Thermoplastics flow more easily as temperature rises, while thermosets quickly solidify after heating. Crystalline materials are sensitive to cooling speed, amorphous ones flow more steadily, and fiber-filled resins show fiber orientation that affects warpage and strength.

Plastic molding Service with mold flow analysis

Benefits of Mold Flow Analysis

Mold flow analysis provides several key benefits in the injection molding process:

Optimizing Part and Mold Design

Allows testing of different part designs, materials, and processing conditions virtually before production, reducing costly iterations and prototyping.

Helps determine optimal gate locations, wall thicknesses, and cooling layouts for balanced filling and efficient packing.

Enables identification and correction of potential defects like weld lines, air traps, sink marks, and warpages early in the design stage.

Improving Part Quality and Consistency

Simulates the flow of molten plastic into the mold cavity, predicting filling patterns and potential quality issues, such as short shots, voids, and warpages.

Analyzes critical parameters like pressure distribution, temperature variations, shear stress, and fiber orientation within the cavity.

Ensures mold cavities are filled uniformly and consistently, mitigating defects and enhancing part integrity.

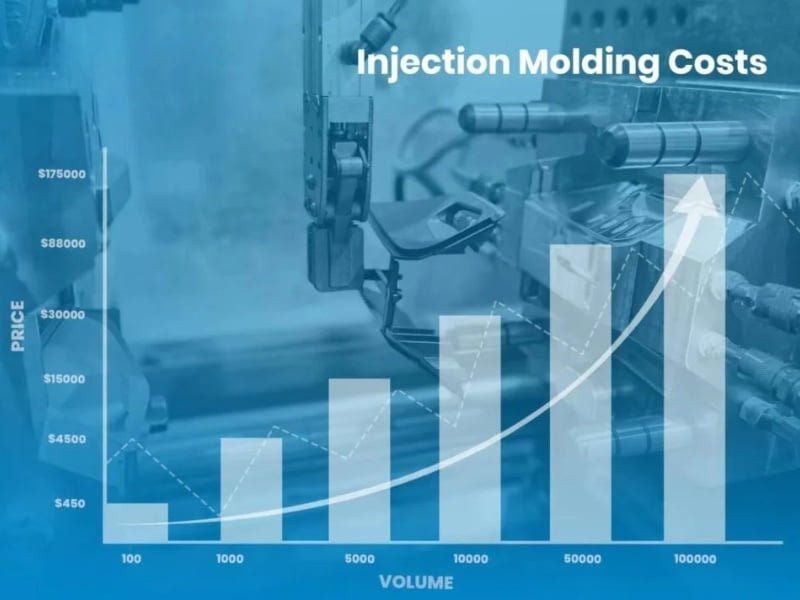

Reducing Lead Times and Costs

Eliminates the need for extensive trial-and-error processes and costly mold reworks by identifying issues upfront.

Optimizes cycle times, often reducing them by 10-30%, leading to significant productivity improvements and cost savings.

Evaluating Materials and Processes

Allows testing and comparison of different resin materials and their flow characteristics before production.

Enables optimization of process parameters like packing pressure, melt temperature, and filling time for efficient molding.

How Does Mold Flow Analysis Improve Mold Design?

Mold flow analysis significantly improves mold design by providing valuable insights and data that help optimize various aspects of the mold’s geometry and configuration. Here’s how mold flow analysis contributes to enhancing mold design:

Identifying Potential Issues Early

Mold flow analysis allows designers to simulate the flow of molten plastic within the mold cavity before physical production begins. By doing so, designers can identify potential issues such as air traps, weld lines, sink marks, and short shots early in the design phase. This enables them to make necessary adjustments to the mold geometry to mitigate these issues and improve part quality.

Analysis and Optimizing Wall Thickness

Mold flow analysis identifies areas with excessive or insufficient wall thicknesses that can lead to issues like sink marks, short shots, or overpacking. It enables optimization of wall thicknesses to reduce material usage while maintaining part strength and quality.

Analysis and Optimizing Gate Location

It simulates the flow patterns of molten plastic to determine the optimal gate locations for balanced filling and packing of the mold cavity. Based on the simulation results, design modifications, and process adjustments. Proper gate positioning ensures even distribution of material, minimizing defects like weld lines, air traps, and uneven shrinkage.

Balancing Flow and Cooling

Mold flow analysis allows designers to analyze the flow of plastic material within the mold cavity and predict how it will cool and solidify to form the final product. By optimizing the flow and cooling process, designers can achieve more uniform part quality, reduce cycle times, and minimize warpage and shrinkage issues. Mold flow analysis helps designers determine the optimal placement and configuration of cooling channels within the mold to achieve efficient heat transfer and uniform cooling.

Material Selection and Testing

The software enables virtual testing of different plastic materials and their flow characteristics within the mold design, including viscosity, density, thermal conductivity, and specific heat. These material properties are crucial for accurately simulating the flow behavior of the molten plastic. This information guides optimal material selection and processing parameters for efficient molding.

Analysis and Optimizing Runner and Sprue Design

The design of runners and sprues in the mold significantly affects the flow of plastic material during the injection molding process. Mold flow analysis helps designers optimize the size, shape, and configuration of runners and sprues to minimize pressure drop, reduce flow resistance, and ensure consistent filling of the mold cavity. By optimizing runner and sprue design, designers can improve part quality, reduce material waste, and enhance overall process efficiency.

Validating Mold Design Changes

Mold flow analysis serves as a valuable tool for validating design changes and optimizations before implementing them in physical molds. By simulating different design iterations and configurations, designers can assess the impact of changes on part quality, filling behavior, and cooling efficiency. This allows them to make informed decisions and ensure the success of the mold design before investing in expensive tooling.

MoldFlow Analysis Case Study

A customer needed to produce a polypropylene (PP) automotive interior panel with complex ribs and thin-wall sections. To ensure smooth filling and avoid potential defects, a mold flow analysis was performed before mold fabrication.

The CAD model of the panel was imported into the software, meshed, and PP material data was selected from the database. Process parameters such as melt temperature, injection pressure, and gate positions were defined according to initial design assumptions.

The filling simulation revealed potential air traps near deep ribs and weld lines at intersecting features. During packing and cooling analysis, areas of possible warpage and uneven shrinkage were also identified.

Based on these results, the gate layout was adjusted, cooling channels were optimized, and rib thickness was slightly modified. The analysis results were then shared with the customer, who made corresponding design adjustments, resulting in smooth cooperation and a final solution that satisfied their requirements.

Conclusion with Flow Analysis of Injection Molds

Mold flow analysis is an important tool in modern manufacturing, especially plastic injection molding. By using mold flow analysis, zhongde can optimize mold design, enhance part quality, and streamline production processes with precision.