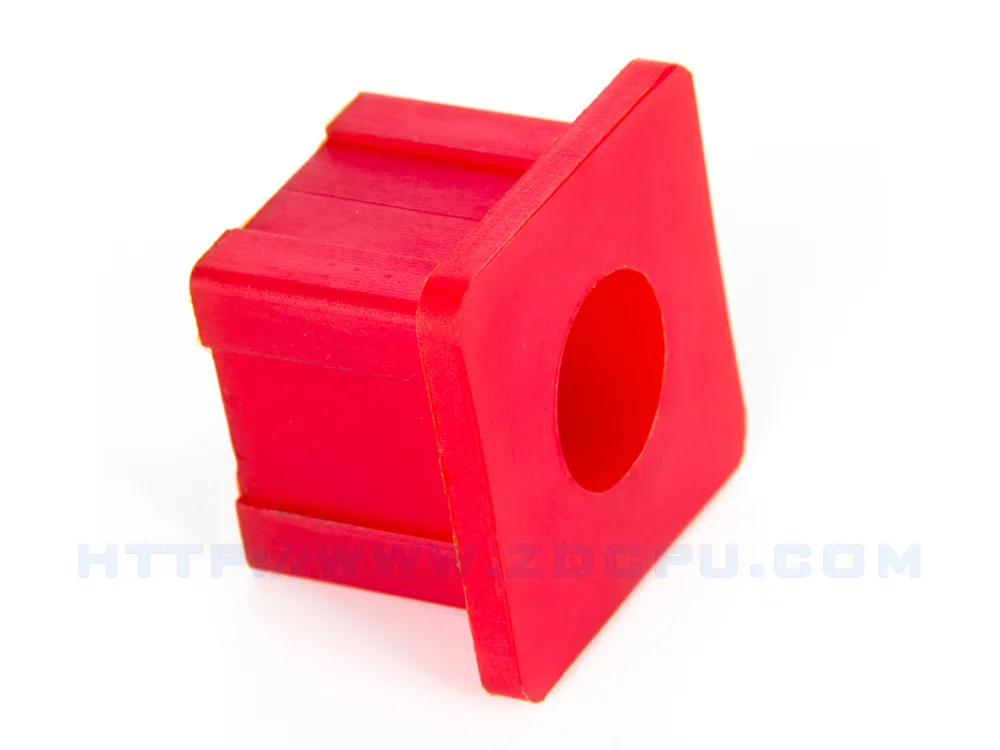

Low volume injection molding is an ideal solution for businesses needing specialized, custom plastic and rubber parts in smaller quantities. Low volume plastic mold production for specialized parts allows manufacturers to respond quickly to changes in design or demand without significant upfront investments. we’ll explore the key benefits and considerations of using low volume production molds for both plastic and rubber components.

What is Low Volume Injection Molding?

Low volume injection molding, also called small run injection molding, is a plastic molding manufacturing that typically involves producing fewer than 10,000 pieces, often ranging from 100 to 1,000 units. At its core, it involves the creation of plastic or polymer parts in quantities that are significantly smaller than those associated with high-volume production methods. This approach has gained prominence for its ability to deliver cost-effective solutions, rapid prototyping capabilities, and unparalleled flexibility in part design.

Low Volume Injection Molding Service

How Low-Volume Plastic Injection Molding Works?

The low-volume injection molding process begins with the rapid creation of a mold using materials like aluminum or soft steel. Molten plastic is then injected into the mold cavity and allowed to cool and solidify, forming the final part. The entire process consists of product design, mold creation, injection molding, post-processing of parts, and final inspection to complete the production of small batches.

Advantages of Plastic Low Volume Injection Molding

1. Lower Tooling Costs

Low-volume production typically uses molds made from materials like aluminum or soft steel, which are significantly less expensive than the hardened steel molds used for high-volume runs. These savings come from both lower material and reduced machining costs, making the initial investment more affordable.

2. Shorter Lead Times

Aluminum molds are quick to machine and easy to modify. This rapid mold production drastically shortens the overall lead time from design to production, allowing you to bring your products to market much faster than with the 4-8 week lead times often required for steel molds.

3. Higher Production Efficiency

Aluminum’s superior thermal conductivity over steel allows parts to cool and solidify faster. This increased efficiency means more parts can be produced in the same amount of time, directly lowering the cost per part and making it a highly cost-effective solution.

4. Greater Design Flexibility

The tooling for low-volume molding is easier and more affordable to modify. This flexibility is crucial for new product development, as it allows for rapid design iterations and quick adjustments to a product’s geometry, significantly reducing the risk and cost associated with design changes.

5. Reduced Financial Risk

For new products with uncertain market demand, low-volume injection molding enables small-scale production at a minimal cost. This allows you to test the market, validate your product, and gather valuable feedback without the financial risk of large inventory and capital investment.

Disadvantages of Plastic Low Volume Injection Molding

1. Limited Volumes

As the name suggests, this method is for smaller quantities. If your product’s demand grows unexpectedly, switching to high-volume production requires new tooling, which can be a significant extra cost.

2. Reduced Mold Life

Molds made from softer materials like aluminum are not as durable as hardened steel molds. They wear out faster over time, which may require you to replace them and increases maintenance costs.

3. Design Constraints

Softer mold materials can’t achieve the same tight tolerances and fine surface finishes as steel. This can be a problem for parts that require high precision and quality.

Key Considerations of Low Volume Injection Molding

Choose the Right Material for the Project

Different materials offer distinct properties, including strength, flexibility, temperature resistance, and durability. Selecting the appropriate material for low volume plastic injection molding is a pivotal decision.

Finesse a Part’s Finish

Achieving the desired surface finish is crucial, as it can impact both aesthetics and functionality. Work closely with mold designers to finesse the part’s finish, considering factors like texture, gloss, and any specific requirements for your application.

Uniform Wall Thickness

Too thick can lead to cooling issues, while too thin can result in structural weaknesses. It’s important to consider the appropriate wall thickness to avoid issues like warping or sink marks during the cooling process. Ideally, Injection molding wall thicknesses should typically stay within the range of 0.04 to 0.14 inches (1 to 3.5mm).

Rounded Edges and Corners

Incorporate rounded edges and corners whenever possible. Sharp angles can be challenging to mold and may lead to part defects.

Avoid Undercuts

Minimize or eliminate undercuts in your design, as they can complicate the ejection of the part from the mold.

Proper Draft Angles:

Draft angles are essential for ensuring that the molded part can be easily removed from the mold without damaging it. All vertical faces should have at least 0.5 degrees of draft, but if the part design allows, it’s preferable to have 2 to 3 degrees of draft. In some cases, complex surfaces may even require as much as 5 degrees of draft.

Applications of Low Volume Injection Molding

Rapid Prototyping

Low-volume injection molding is a vital tool in the realm of rapid prototyping. Designers and engineers can swiftly transform the concepts into tangible prototypes. It enables thorough testing, design tweaks, and refinements, ensuring that the final product meets or exceeds expectations. In today’s competitive market, being the first to market with a high-quality product is often the key to success, and low-volume molding plays a pivotal role in achieving that goal.

Low Volume Parts Production

In the world of manufacturing, not every project calls for mass production. Sometimes, you need just a small batch of parts. This is where low-volume injection molding shines. Many niche products, limited production runs, and specialized components fall into this category. Whether you’re creating unique automotive parts, medical devices, or specialized electronic components, low-volume injection molding caters to the demand for precision and quality in smaller quantities.

On-Demand Injection Molding

The modern manufacturing landscape demands adaptability and efficiency. Enter low-volume injection molding as the solution for on-demand manufacturing. Companies can order custom parts tailored to their exact specifications, whether it’s specific shapes, materials, or unique features. This flexibility minimizes excess inventory, streamlines production, and ultimately leads to significant cost savings.

Alternatives to Low Volume Injection Molding

CNC Machining

CNC Machines can be highly automated and precise. CNC machining is an alternative to injection molding for lower part volumes, especially when parts have complex geometries. Multi-axis CNC machines are often required for intricate designs.

CNC Machining Service

3D Printing

3D printing offers the advantage of creating parts with highly complex geometries that may not be achievable through other manufacturing methods. It’s especially popular for prototyping.

Thermoforming

Thermoforming, particularly vacuum forming, is a viable option for thinner parts with simpler designs. It’s a cost-effective method for creating parts with larger surface areas.

Urethane Casting

Urethane casting can produce durable components that closely resemble injection molded parts without a significant tooling investment. This method is particularly valuable when you need robust prototypes or low-volume production.

Zhongde PU Casting Service

Conclusion with Small Volume Injection

Low volume injection molding isn’t merely a modern manufacturing process, it’s a pathway to innovation, cost-effectiveness, and quality. It empowers businesses to bring their ideas to life swiftly, respond to market demands, and deliver products that meet the highest standards.

When launching your next project, turn to Zhongde for expert low volume injection molding services.