Low-Density Polyethylene (LDPE) injection molding is a pivotal manufacturing method widely used to produce flexible, durable LDPE plastic components across diverse industries.

What Is LDPE and Its Material Characteristics?

LDPE, or low-density polyethylene, is a lightweight, flexible thermoplastic polymer known for its softness and toughness. Its unique molecular structure is highly branched, which reduces density and crystallinity, resulting in excellent flexibility, impact resistance, and chemical stability. LDPE is easier to process compared to denser polyethylene types because it melts at a lower temperature and requires less pressure during injection molding.

What is LDPE Injection Molding?

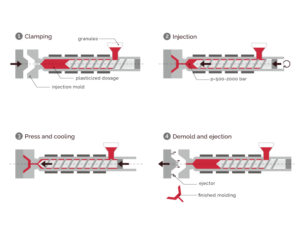

LDPE injection molding is a highly efficient manufacturing process that transforms LDPE granules into precision-engineered parts. The process begins with heating LDPE pellets to their melting point, typically between 180°C and 240°C, until they form a flowable melt. This molten plastic is then injected under high pressure into a designed mold, where it fills the cavity, taking on the desired shape. Once filled, the molten polymer cools and solidifies. After cooling, the solidified part is ejected, ready for use or further processing.

Advantages of LDPE Injection Molding

Injection molding of LDPE offers several distinct advantages that make it a preferred process for plastic parts manufacturing.

- High Flexibility and Impact Resistance: LDPE parts exhibit excellent toughness and the ability to absorb shocks and impacts without cracking or breaking.

- Ease of Processing: LDPE has a relatively low melting point and melt viscosity, which leads to smoother flow in molds and shorter cycle times.

- Economic Cost: As a commodity thermoplastic, LDPE resin is widely available and low-cost. Combined with efficient processing, it enables economical production of large-volume runs.

- Chemical and Moisture Resistance: LDPE is chemically inert to many acids, bases, and solvents, and has good moisture barrier properties.

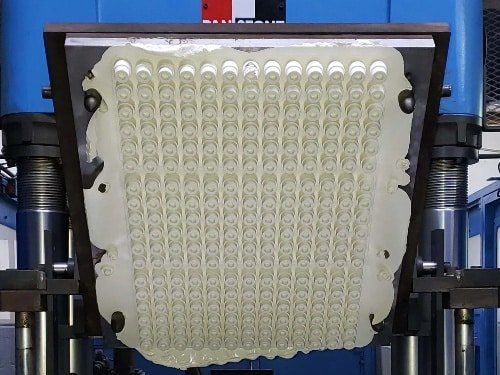

- Capability for Complex Shape Molding: The material’s melt flow properties enable it to fill intricate mold designs, allowing for thin walls, detailed ribs, and small features.

- Lightweight: Parts produced via LDPE injection molding are lightweight without sacrificing durability, which is beneficial.

- Biocompatibility for Medical Use: LDPE’s non-toxic nature and sterilizability make it a standard choice for disposable medical devices manufactured by injection molding.

- Recyclability: LDPE’s recyclability supports environmentally conscious manufacturing, allowing for sustainable production without compromising quality.

LDPE Injection Molding Service

Conditions for LDPE Injection Molding Process

Achieving optimal results in LDPE molding requires precise control over process parameters. The following conditions is an effective LDPE injection molding processing guide:

Melt Temperature

The melt temperature for LDPE typically ranges from 180°C to 240°C. This range ensures the material achieves a uniform, flowable state without thermal degradation. For thinner parts, a higher temperature within this range may be used to improve flow, while thicker parts benefit from lower temperatures to prevent warping.

Mold Temperature

Mold temperature generally ranges from 20°C to 60°C. Maintaining a uniform and consistent mold temperature is essential to reduce internal stresses, minimize warping, and improve surface finish. Cooling channels should be well designed to ensure even heat removal.

Injection Pressure

Injection pressures of 500 to 1500 bar are employed, depending on mold complexity and part geometry. Higher pressures compensate for LDPE’s lower melt strength and are essential for filling thin sections or complex geometries without voids or incomplete filling.

Injection Speed

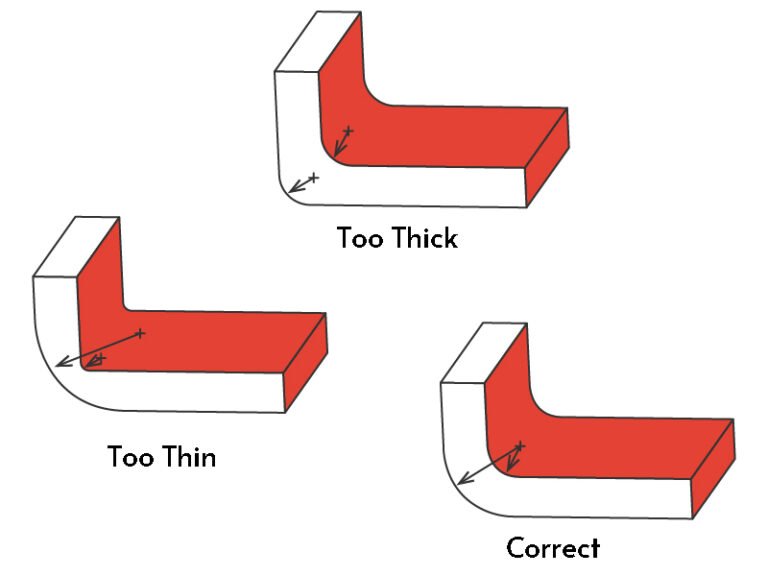

Medium to high injection speeds are recommended to rapidly fill the mold cavity, reducing the risk of premature cooling and weld lines. Injection speed needs optimization to balance shear heating effects and avoid overshoot that leads to defects like flash.

Comparison of LDPE and HDPE Injection Molding

While both LDPE and HDPE are polyethylenes, their distinct properties lead to different applications and processing requirements in injection molding. The table below provides a detailed comparison:

| Aspect | LDPE Injection Molding | HDPE Injection Molding |

|---|---|---|

| Molecular Structure | Highly branched, low crystallinity | Linear, high crystallinity |

| Density | 0.91–0.94 g/cm³ | 0.941–0.965 g/cm³ |

| Melting Point | 105 – 115°C | 125 – 135°C |

| Flexibility | High, ideal for soft, pliable products | Lower, suited for rigid, durable parts |

| Tensile Strength | 7–20 MPa | 20–40 MPa |

| Cycle Time | Generally shorter | Usually longer |

| Applications | Flexible packaging, films, squeeze bottles | Rigid containers, pipes, automotive parts |

| Chemical Resistance | Good, but permeable to gases | Better, lower permeability |

| Processing Ease | Easier due to lower melting point and better flow | Slightly more complex due to higher temperatures |

| Cost | Lower | Higher |

Applications of LDPE Injection Molded Parts

LDPE injection molding finds extensive applications across numerous industries owing to its unique material attributes:

- Packaging: Flexible films, bags, squeezable bottles, and lids.

- Medical Devices: Disposable syringes, tubing, IV containers, surgical drapes, and components.

- Agriculture: Films for greenhouses, irrigation tubing, seed trays, and protective coverings.

- Automotive: Interior trim panels, wire insulation, and flexible components.

- Electrical: Protective enclosures, cable sheathing, connectors.

- Consumer Goods: Toys, household items, storage containers, and flexible parts.

- Construction and Industrial: Vapor barriers, lining sheets, and protective coatings.

Partner Zhongde for LDPE Injection Molding

With advanced equipment and experience in LDPE injection molding processing guide principles, Zhongde delivers professional parts tailored to client specifications. Welcome to contact Zhongde and get a custom plastic injection molding solution.