What is an injection molding lifter and slider in mold? They are important components of an injection mold to make the complex mold design come true. In the previous posts, we have introduced the injection molding lifter and injection molding slider already. Today, we will compare those two important mold components, learn what the differences are, the relationships, and how to choose the right mold design in the injection molding process.

Understanding of Injection Molding Lifter and Slider

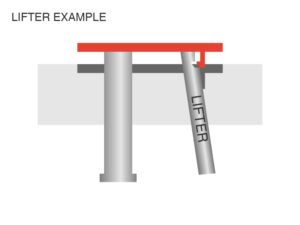

What is an Injection Molding Lifter?

An injection molding lifter consists of a blade- or pin-shaped body, an ejector plate, a retainer plate, and a locking block. When the mold opens, it moves upward at an angle to release parts with internal undercuts that cannot be ejected straight. As the ejector plate moves, the lifter slides along its angled path, pushing the part out smoothly. Read our previous blog to learn more about injection molding lifters.

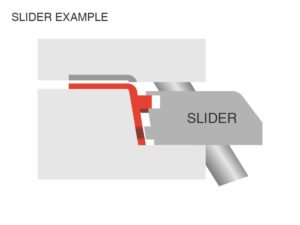

What is an Injection Molding Slider?

An injection molding slider is made up of a slider body, guide pin, wedge or angle pin, wear plate, locking block, and press block. These components work together to create and release side features such as holes or undercuts that a straight-pull mold cannot form. During molding, molten plastic fills around the slider’s forming surface. When the mold opens, the guide pin drives the slider laterally, freeing the part for ejection. The slider mechanism is usually made of hardened tool steel and equipped with cooling channels to prevent warping and ensure accuracy in mold design. Interested in learning more about injection molding sliders? Read our previous blog about the injection molding slider.

Custom Mold and Tooling Design

What is the Difference Between Lifter and Slider in Injection Molding?

Lifters and sliders in mold are key mold components used to form undercuts and side features. Though similar, they function differently. This table highlights their main differences for better mold design and part quality.

| Item | Lifter | Slider |

|---|---|---|

| Function | Ejects parts with internal undercuts by combining vertical and angled movement. | Creates external side features such as holes, slots, or side threads by moving laterally. |

| Movement Direction | Moves upward and outward at an angle (typically 5°–15°) during ejection. | Moves horizontally or along a fixed angle during mold opening. |

| Design Complexity | Relatively simple; mainly depends on ejector plate angle and alignment. | More complex; requires precise coordination of wedge, guide pin, and lock system. |

| Cost | Lower initial cost and easier to manufacture. | Higher cost due to added parts and machining requirements. |

| Maintenance & Durability | Less wear; hardened steel improves lifespan. Minimal maintenance needed. | Requires regular lubrication, alignment, and cleaning to prevent jamming. |

| Cooling Requirement | Typically cooled indirectly through surrounding mold plates. | Often includes dedicated cooling channels to prevent warping and distortion. |

| Applications & Advantages | Ideal for parts with internal undercuts like clamps, clips, threaded bosses, or hollow sections. Its angled motion ensures smooth ejection without damaging delicate features. | Suitable for parts with external side features like side holes in automotive panels, slots in enclosures, or undercut tabs. Lateral motion allows precise formation and safe release of complex geometries. |

| Disadvantages | Limited by part thickness and undercut depth; risk of part sticking if not aligned. | More components increase cost and maintenance; requires space for movement. |

How Sliders and Lifters Work Together in Injection Molds?

Injection molding lifter and slider can work together to create intricate and complex part designs beyond traditional straight-pull molds’ capabilities. Manufacturers can produce parts with multi-level undercuts, threads, holes, or unique geometries by combining lifters for external undercuts and sliders for internal features. The coordination between lifters and sliders allows for the formation of complex mechanisms and moving parts within the molded components, enabling the production of sophisticated products for various industries.

Complementary Use of Sliders and Lifters in Injection Molding

- Automotive Parts:

Automotive Door Handle In automotive components such as door handles, lifters are used to form internal undercuts, like clips or hooks. During mold opening, the lifter moves vertically and at an angle to release these hidden features, ensuring smooth ejection. Sliders, on the other hand, create external side features such as side holes or decorative grooves. They move laterally or along a fixed angle to free these features without interfering with the part, preserving its shape and functionality.

- Electrical Connectors:

Electrical Connectors In electrical connectors, lifters produce internal locking features or clips that secure pins and ensure precise alignment. The angled motion of the lifter ensures these internal undercuts are released during mold opening. Sliders form external features such as side slots or guide rails that facilitate insertion or alignment. Their sideways movement prevents damage to the delicate pins and maintains precise tolerances.

- Medical Devices:

Medical Devices In medical devices, lifters are used to form internal undercuts like hooks, locks, or snap-fit features within components, allowing for secure assembly or functional connections. The vertical and angled motion of the lifter releases these internal geometries safely. Sliders create external features such as side holes, channels, or guide surfaces for assembly or operational use. Lateral movement of sliders ensures these external features are properly formed and do not deform during ejection, maintaining the device’s precision and reliability.

Injection Molding Slider vs Lifter: Which One to Choose?

Selecting the right mechanism(lifter or slider)requires analyzing how the part is molded and which features need precise movement. Considering factors such as mold layout, part complexity, and production volume helps determine the optimal choice for smooth operation and consistent part quality.

Part Design

Examine the part design and identify the features that require undercuts or internal shapes. If the part has internal features that cannot be achieved with a simple straight-pull mold, sliders may be the better choice.

Mold Complexity

Consider the complexity of the mold design and construction. Lifters are relatively simpler and easier to integrate into the mold compared to sliders, which may require additional components and advanced mold design.

Production Volume

Evaluate the production volume. For low to medium volumes, lifters may be more cost-effective and practical. However, for high-volume production, sliders can offer better efficiency and reduced cycle times.

Cost Considerations

Analyze the cost implications of using lifters or sliders. Lifters are generally more economical and easier to implement, while sliders may involve higher initial costs and maintenance.

Part Release Requirements

Determine the ease of part release. If the part can be easily released with simple lifters, it might be a more straightforward choice. However, if complex internal features necessitate the use of sliders, they will be essential for proper part ejection.

Mold Life and Maintenance

Consider the lifespan and maintenance requirements of the mold. Lifters might have longer life spans and lower maintenance needs compared to sliders.

Zhongde: Custom Injection Molding Solutions

In summary, lifters and sliders each serve unique roles in injection molding, with lifters managing internal undercuts and sliders creating side features. Together, they enable the production of complex, high-precision parts across various applications. At Zhongde, we specialize in custom injection molds solutions, using our expertise in both lifter and slider design to handle intricate part geometries.