Silicone compression molding is a manufacturing process used to produce parts from silicone rubber materials. Silicone compression molding is applied in industries such as automotive, medical, and electronics due to the material’s properties like temperature resistance and flexibility.

What is Silicone Compression Molding?

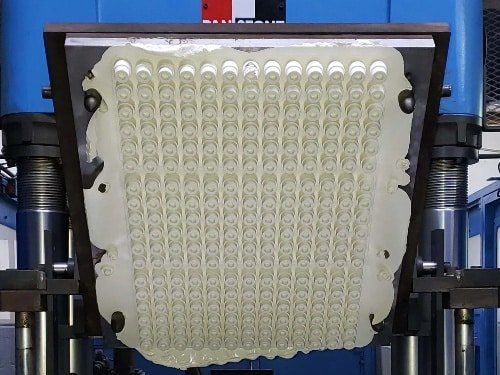

Silicone material is a polymer known for its chemical stability, electrical insulation, and ability to withstand temperatures from -55°C to 300°C. Silicone rubber compression molding utilizes these features to produce items that maintain performance in harsh conditions. Silicone compression molding process is a process where a premeasured amount of uncured silicone rubber is placed into an open, heated mold cavity. When the mold closes, the silicone is compressed and cured (vulcanized) under heat and pressure, allowing the material to flow and fill the cavity, forming the desired part shape.

Silicone Compression Molding and Injection Molding Differences

Silicone rubber compression differs from other methods by relying on mechanical force rather than injection. The following table outlines the differences between silicone compression molding and injection molding.

| Item | Silicone Compression Molding | Silicone Injection Molding |

|---|---|---|

| Process Description | Uncured silicone placed in open mold, compressed and heated. | Liquid silicone injected into closed mold under pressure. |

| Tooling Cost | Lower, simpler molds. | Higher, complex molds with runners. |

| Material Waste | Minimal, excess trimmed post-cure. | Higher due to sprues and runners. |

| Part Complexity | Suitable for simple to moderate geometries. | Handles complex shapes with thin walls. |

Advantages of Silicone Compression Molding

Silicone compression molding provides several benefits in manufacturing, making it a preferred method for producing silicone rubber components. These advantages are outlined below with subheadings for clarity.

Lower Tooling Costs

Molds for silicone compression molding are simpler in design, often made from basic steel alloys, which reduces initial expenses compared to other processes.

Design Flexibility

Silicone compression allows for adjustments in mold cavities to accommodate various shapes and sizes, from small gaskets to larger seals. This adaptability supports customization without extensive retooling.

Low Material Waste

Excess silicone can be minimized by precise weighing, and any flash is easily removed after curing. Silicone compression moulding is efficient for materials that are difficult to handle in liquid form.

Insert Integration

The process supports the integration of inserts or overmolding with other materials, expanding its use in composite assemblies. This is beneficial for creating complex assemblies in single operations.

Silicone Compression Molding Mold Design

Mold design in silicone rubber compression molding focuses on durability and precision, with considerations for material behavior and production requirements. The key aspects are outlined below.

Mold Structure

The mold consists of two halves: the cavity and the core, which form the part shape when closed. Design accounts for part geometry, wall thickness, and draft angles of 1-3 degrees to facilitate demolding.

Material Selection

Common mold materials include P20 steel for general use, offering good machinability and hardness for up to 100,000 cycles.

Venting System

Small vent holes placed strategically at the highest points of the mold allow trapped air to escape during compression.

Gates Design

Typically, the gate is placed at a thick section to ensure that the material fills the cavity completely. The gate should be as small as possible to reduce flashing.

Runner System

Silicone rubber compression molds generally use a simple runner system to deliver material into the cavity. The design of the runner should minimize material wastage while ensuring uniform distribution.

Shrinkage Compensation

Shrinkage: Silicone rubber experiences a certain degree of shrinkage during curing. Mold cavities are oversized by 1-2% to account for material shrinkage during curing. CAD software simulates material flow to identify potential issues early.

Silicone Compression Molding Process Flow

- Material Preparation

Silicone rubber is mixed with curing agents and pigments if needed. The compound is weighed accurately to match the mold volume, typically with a 5-10% excess for flash. - Mold Preheating and Filling

Molds are cleaned thoroughly and preheated to optimal temperatures to reduce viscosity and promote flow. Silicone is placed into the open mold cavity, often as a sheet or preform for uniform distribution. - Compression

The mold halves are closed using a hydraulic press applying 10-20 MPa of pressure for 1-5 minutes. This forces the material to fill the cavity completely. - Curing

The mold is held at 160-180°C for 3-7 minutes, depending on part thickness, to vulcanize the silicone, forming a solid elastomer. - Cooling and Demolding

The molded part is cooled within the mold to stabilize shape and reduce internal stresses. After cooling, the mold opens and the part is removed. - Post-Processing

Trimming removes flash with scissors or dies. Inspection uses visual or dimensional checks to ensure quality. Precaution: Calibrate equipment for repeatability.

Compression Molding Service

Applications of Silicone Compression Molding

Silicone compression molding is used in various sectors for its material properties.

- Automotive: Seals, gaskets, vibration dampeners.

- Medical Devices: Tubing, seals, and implantable components.

- Electronics: Keypads, connectors, insulating parts.

- Consumer Products: Kitchenware, wearable bands, protective cases.

Common Issues in Silicone Compression Molding and Solutions

Several issues can arise in silicone compression molding. Below are common problems and their solutions.

Flash Formation: Excess material escapes due to overfilling or poor alignment. Solution: Weigh material precisely, maintain mold alignment and improve mold venting.

Voids and Bubbles: Voids form from trapped air. Solution: Add vents or use vacuum assistance before compression.

Under-Curing: Soft or sticky parts from insufficient heat/time. Solution: Extend cure cycles and monitor temperatures.

Over-Curing: Brittleness or discoloration from excessive heat. Solution: Use timers and control temperatures.

Warping or Shrinking: Caused by uneven cooling. Solution: Mitigated by controlled cooling rates and mold temperature uniformity.

Dimensional Inaccuracies: Caused by mold wear or inconsistent pressure. Solution: Inspect molds regularly and calibrate presses.

Surface Defects: Roughness from contaminated molds. Solution: Clean molds and apply release agents.

Conclusion

Silicone compression molding serves as an effective method for producing silicone rubber parts across industries. It balances cost, quality, and flexibility, though it has limitations in speed and volume. Zhongde provide professional silicone compression molding service, welcome to contact and get a tailored compression molding solution.