Have you ever wondered what makes a plastic thread design successful and reliable in injection molding applications? Designing threads for plastic components is not as same as metal thread standards. It requires adapting the geometry and material selection based on the unique characteristics of plastics. In plastic parts design guide, threads are not merely functional features, they are critical for assembly strength, durability, and performance.

Key Parameters in Plastic Thread Design

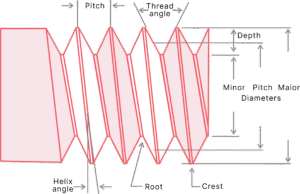

When designing threads for injection-molded plastic parts, These parameters influence not only the mechanical strength of the threads but also the ease of manufacturing and long-term durability.

Thread Pitch

The thread pitch is the distance between adjacent thread crests, which influences holding power and moldability. Coarser threads are easier to mold and more robust in plastic, while finer pitches offer precision at the cost of mold complexity.

Thread Angle

The thread angle, often 60 degrees, is the angle between two adjacent thread surfaces. The thread angle determines how the load is distributed along the thread flanks.

Thread Depth

Thread depth is the distance from the crest to the root. It affects the engagement and holding power of the thread. Deeper threads offer greater holding strength but can introduce stress concentrations in surrounding plastic, especially in thin-walled components.

Major, Minor, and Pitch Diameters

The major diameter is the crest outermost diameter of the thread, the minor diameter is the root innermost, and the pitch diameter is the effective diameter between them. They must be coordinated with mating elements for proper fit and strength.

Helix Angle

The helix angle defines the inclination of the thread around the core. A moderate helix angle improves assembly ease while minimizing deformation during installation. Excessive helix angles can lead to uneven engagement and difficulty in demolding.

Crest and Root Geometry

Sharp thread crests and roots concentrate stress and can cause cracks or breakage. For plastic threads, rounded crests and roots are recommended. This approach reduces stress concentrations, facilitates molding, and improves part longevity.

Thread Types and Their Applications

Plastic threads can be classified in multiple ways depending on their function, usage, or shapes. Understanding these categories helps designers choose the appropriate thread type for injection-molded components.

1. Functional Classification

- Fastening Threads: Fastening threads are designed to join two or more components securely. Moderate load-bearing capacity, coarse pitch preferred for plastics. The common applications are electronics enclosures, consumer product housings, and plastic assemblies requiring repeated disassembly.

- Sealing Threads: Sealing threads are optimized to prevent fluid or gas leakage. They often combined with smooth crests or circular arc profiles for better sealing. The common applications are bottles, containers, fluid fittings, caps, and closures for liquids.

- Power Transmission Threads: The power transmission threads are designed to transmit torque or linear motion. Square and trapezoidal threads are common due to their high load capacity and even stress distribution. The common applications are lead screws, plastic actuators, pump housings, and adjustable mechanisms.

- Self-Tapping Threads: The self-tapping threads created their own mating thread during assembly. Reduces mold complexity and allows assembly in pre-drilled holes. The common applications are light mechanical components, low-volume prototypes, and applications requiring simplified assembly.

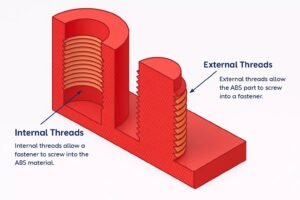

2. Usage-Based Classification

- External (Male) Threads: External threads located on the outside of a component. Easier to mold and inspect, less prone to demolding issues than internal threads. The common applications are bottle caps, knobs, and external fasteners on plastic parts.

- Internal (Female) Threads: Threads located inside a cavity. Requires careful design for depth, pitch, and core demolding. More prone to stripping in small diameters or soft plastics. The common applications are Nut-like features in enclosures, bosses for screws, and internal fittings.

3. Thread Shapes for Plastics

- V-Threads: V-Threads are simple, easy to mold, and have moderate engagement strength. They are commonly used in general assembly threads for consumer electronics, housings, and covers.

- Trapezoidal Threads: They have excellent load distribution and torque transmission, more resistant to stripping than V-threads. The common applications include lead screws, actuators, and adjustable components in plastic assemblies.

- Square Threads: Square threads have high load-bearing capacity, low friction, and are resistant to wear. The applications include power transmission applications, pumps, and linear motion systems.

- Serrated Threads: Serrated threads are one-way torque engagement, reducing loosening, and may act as tamper-proof or locking threads. The common applications are specialized closures, dispensers, and one-way adjustment screws.

- Circular Arc Threads: Circular arc threads have smooth engagement, low stress concentration. They are used in fluid-tight closures, bottle caps, and containers requiring repeated opening and closing.

Recommended Materials for Molded Plastic Threads

Material selection strongly influences thread performance. The common plastic materials are:

POM: POM offers great creep resistance, low friction, high stiffness, and good dimensional stability. Acetal threads maintain their shape under sustained torque and exhibit minimal wear when mated with metal fasteners.

Nylon 6/6: Nylon provides good toughness and flexibility. It absorbs assembly stresses well and resists cracking during screw insertion. Nylon is suitable for internal threads and self-tapping bosses.

ABS: ABS is cost-effective, easily molded, and finishes well. They are commonly used for non-critical, lightly loaded threads.

PC: Polycarbonate delivers high impact strength and transparency, but it is prone to stress cracking under sustained load. Polycarbonate threads are often found in optical or display-related housings.

PP: Polypropylene has lower strength, chemical resistance, and a lower price. It is occasionally selected for large, coarse threads in disposable or low-cost items.

Design Considerations for Molded Threads

Unlike metal threads, plastic threads are more prone to stripping, cracking, and deformation. Designing molded threads for plastic parts requires careful attention to material properties, geometry, and manufacturing constraints.

1. Thread Size and Pitch

Plastic threads should generally use coarse pitch to reduce stress concentration and improve manufacturability. Internal threads should be at least 2 mm in diameter, external threads at least 4 mm, and the engagement length should not exceed 1.5–2 times the thread diameter. This helps reduce pitch errors and improves reliability.

2. Wall Thickness and Geometry

The surrounding wall should at least match the thread depth, ideally 1.5 times the minor diameter. Avoid sudden thickness changes, which may introduce molded-in stress. If the thread ends near a load-bearing flange, add a smooth radius transition to reduce stress buildup.

3. Crest and Root Design

Avoid sharp edges. Rounded crests and roots reduce stress concentration and lower the risk of cracking. Even with rounding, the thread root remains a weak area, so the overall part geometry and adjacent structures should help distribute load.

4. Draft Angle and Undercuts

Include 1–2 degrees of draft for easier demolding. Threads are undercuts, especially internal ones, so collapsible cores or side actions may be required. These solutions increase tooling cost but ensure accurate injection molding thread design.

5. Material Selection

Material choice directly affects thread performance. ABS, POM, and nylon are reliable options for internal threads because they resist stress cracking and maintain dimensional stability. For applications requiring repeated tightening or high strength, consider reinforced grades or using metal inserts.

6. Thread Termination and Stops

Thread ends are critical points for stress concentration. Avoid designing the thread to end directly into a tool groove or transition cone. Include a non-threaded margin of 0.2–0.8 mm at the start and end of threads to prevent cracking and deformation.

7. Assembly Considerations

Plastic threads must be designed considering the mating part. Avoid pairing metal male threads with plastic female threads unless the design includes reinforcement. Ensure consistent pitch and rotation direction when using multiple thread segments, especially for unscrewing mechanisms.

8. Best Practices Summary

- Use coarse pitch and maintain minimum thread diameters for strength.

- Ensure uniform wall thickness and smooth transitions near threads.

- Round crests and roots to reduce stress.

- Apply draft angles to facilitate demolding.

- Select materials suitable for intended loads, repeated use, and environmental conditions.

- Include thread stops and non-threaded margins at terminations.

- Consider inserts or segmenting for high-stress or complex threads.

Alternatives to Direct Molded Threads

In some cases, designing thread features directly into the molded part is not the most practical solution. Alternative solutions are available:

Post-Mold Machining: Cut or tap threads after molding. Best for prototypes and low-volume production.

Self-Tapping Screws: For components designed with pre-formed holes or bosses, self-tapping screws can cut threads in situ, reducing mold complexity.

Metal Thread Inserts: Provide high strength, wear resistance, and repeated-use durability. Can be overmolded during injection or installed post-molding.

Snap-Fits and Quarter-Turn Fasteners: Eliminate threads for permanent or semi-permanent assemblies.

Conclusion

Properly executed molded thread design not only prevents costly failures and rework but also enhances user experience and product performance. Zhongde provides professional customized plastic parts with threads feature, get a solution for your project.