Carbon fiber has become a vital material in modern engineering and manufacturing due to its unique combination of high strength, low weight, and corrosion resistance. The global market size for carbon fiber was estimated at USD 5.75 billion in 2024 with aerospace and defense applications accounting for approximately 30–35%, wind energy 20–27%, and automotive lightweighting 18–25%.

Among various manufacturing methods, carbon fiber compression molding has become the preferred route for mid-to-high volume production because it combines high material utilization, short cycle times, and excellent repeatability for complex geometries with ribs, bosses, and varying wall thickness.

Carbon Fiber Molding Process

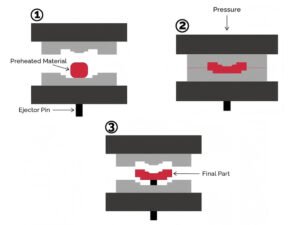

Carbon fiber compression molding is a process in which carbon fiber reinforced blanks (prepreg or thermoplastic organo-sheets/non-woven mats) are placed into a matched metal mold and formed under heat and pressure. The resin flows, fully wets the fibers, and either cures irreversibly (thermoset) or melts and crystallizes (thermoplastic) to produce a finished composite part. This method is widely used for high-performance components in automotive, aerospace, and industrial applications.

Step 1. Blank Preparation and Cutting

Prepreg sheets or sheet molding compound (SMC) are weighed and cut to the required charge pattern. Fiber orientation and ply stacking sequence are controlled to achieve 55–70% fiber volume fraction.

Step 2. Performing (Recommended)

The cut stack is placed into a low-pressure preform tool and lightly compressed at 80–100°C to create a rigid tacky preform that prevents fiber wash or wrinkling during final molding.

Step 3. Mold Loading and Heating

The mold is preheated to a specific temperature before the material is placed inside. The preform is transferred and placed in the lower cavity within 10 seconds to avoid premature resin advancement.

Step 4. High-Pressure Closing and Cure

Once the material is positioned within the mold, the molding process begins. High pressure is applied to the mold to consolidate the carbon fiber layers and shape them according to the mold cavity. Cure time ranges from 5 to 15 minutes, depending on part thickness and resin system.

Step 5. Demolding and Finishing

After full cure, the part must be cooled before removal from the mold. The mold opens, and the part can be carefully demolded. Internal mold release agents or in-mold coating enable clean release.

Step 6: Post-Processing

Post-processing may include trimming excess material, sanding edges, drilling, surface preparation, or additional machining.

Carbon Fiber Molding Techniques

The carbon fiber compression molding process is divided into two main categories: thermosetting compression molding and thermoplastic compression molding. These two types have some differences. The following table provides a clear comparison:

| Feature | Thermoset Compression Molding | Thermoplastic Compression Molding |

|---|---|---|

| Material Type | Prepreg sheets or dry fiber with thermoset resin | Sheets or tapes with thermoplastic polymer |

| Material Cost | Higher | Moderate to high |

| Mechanical Strength | Very high, excellent thermal stability | High, slightly lower stiffness and thermal resistance |

| Production Cycle Time | Longer due to curing | Shorter |

| Tooling Requirements | Moderate; mold must withstand heat and pressure | Higher precision molds often needed for thermoplastic flow |

| Typical Applications | Aerospace structural parts, automotive load-bearing components, sporting goods | Automotive panels, lightweight industrial components, recyclable parts |

| Design Flexibility | Moderate; limited ability to adjust post-curing | High; geometry can be modified during reheating |

Carbon Fiber Molding Component

Carbon fiber compression molding produces high-strength, lightweight components with excellent dimensional stability and surface consistency, which are widely used in various applications.

- Automotive structural panels and reinforcements

- Electrical housings and insulation components

- Industrial equipment covers and frames

- Sporting goods and performance products

Selecting the Right Technology for Your Application

Carbon fiber compression molding provides an efficient solution for producing composite parts at mid-to-high volumes. The process achieves high material utilization, consistent part quality, and the ability to form complex geometries with ribs, inserts, and varying wall thicknesses in a single operation. Cycle times are short compared to autoclave or RTM methods, dimensional accuracy remains stable, and overall production costs become competitive when annual volumes exceed several thousand units.

Selecting the appropriate carbon fiber compression moulding technique requires careful consideration of material properties, production volume, part complexity, and end-use requirements. Our team assists clients in evaluating these factors, providing guidance on material selection, mold design, and process optimization.