Aluminum CNC machining supply high precision aluminum parts for industries ranging from aerospace to electronics. This process leverage computer numerical control (CNC) technology to deliver efficiency and quality that manual methods cannot match. We will explore the aluminum CNC machining in this article.

What Is Aluminum CNC Machining?

Aluminum CNC machining is a subtractive manufacturing process where computer-controlled machines cut, drill, mill, and shape aluminum materials into highly precise components. As a part of metal CNC machined parts, it is particularly valued for producing lightweight parts with excellent mechanical and thermal properties.

Benefits of Aluminum CNC Machining

Aluminium CNC offers a host of advantages. Here are the key benefits:

Machinability: Aluminum’s softness relative to steels allows faster cutting speeds with less tool wear.

Lightweight with High Strength: Aluminum is about one-third the density of steel but still maintains remarkable strength, giving it an excellent strength-to-weight ratio.

Corrosion Resistance: Aluminum naturally forms a robust oxide layer that protects against corrosion, minimizing the need for heavy coatings or treatments.

Versatility Across Alloys: From 6061 to 7075, aluminum alloys offer tailored properties suited for different needs, whether structural strength, machinability, or surface finish.

Cost Efficiency: Despite a slightly higher raw material price, the faster machining speeds and reduced post-processing requirements result in overall lower manufacturing costs.

Recyclability: Aluminum is highly recyclable, supporting sustainable manufacturing.

Superior Surface Finish: Aluminum’s lustrous surface can be anodized or painted for enhanced aesthetics and durability.

Precision and Repeatability: With cnc aluminum machining, manufacturers achieve tight tolerances and consistent quality over large production runs.

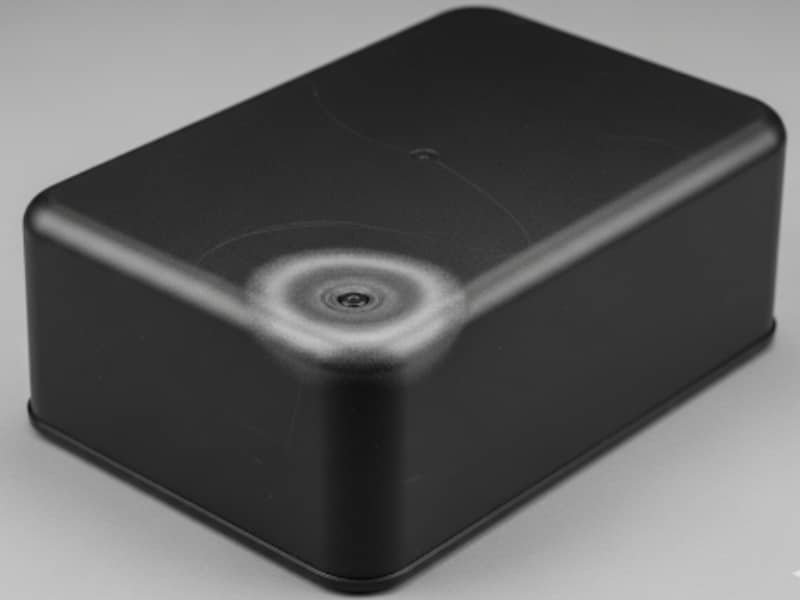

Aluminum CNC Machining

Aluminum CNC Machining Process

The cnc aluminum machining process involves several critical steps, each ensuring precision and quality:

CAD Design and Modeling

The process starts with creating a 3D model of the part in CAD software. The design specifies dimensions, geometries, and tolerances essential for the final product.Material Selection

Appropriate aluminum alloys are selected based on the required mechanical properties and application. Common alloys include 6061, 7075, and 2024.CAM Programming

Engineers translate the CAD model into a CNC program using CAM (computer-aided manufacturing) software, generating tool paths and machining parameters.CNC Machining Execution

The aluminum workpiece is loaded onto the CNC machine. Using various tools, the machine cuts and shapes the aluminum as per the programmed instructions.Post-Processing and Surface Finishing

After machining, parts often undergo deburring, cleaning, anodizing, or painting, etc post processing.Inspection and Quality Control

Rigorous inspection using coordinate measuring machines (CMM), laser scanners, or microscopes verifies dimensions and surface quality.Aluminum CNC Machining Techniques

Several cnc aluminum machining methods are widely used, each optimized for different part geometries and functional needs:CNC Milling

The most versatile technique in cnc machining aluminum, milling rotates multi-point cutting tools to remove material from stationary aluminum blocks. Milling machines range from 3-axis to advanced 5-axis configurations, crafting complex shapes like slots or contoured surfaces.CNC Turning

In turning, the aluminum workpiece rotates while the cutting tool moves along the axis to create cylindrical parts such as shafts, pins, and fasteners. CNC lathes provide exceptional precision in diameter and surface finishes.CNC Drilling

Drilling operations create precise holes in aluminum components for assembly or functional purposes. This process supports creating through holes, blind holes, and complex hole patterns.5-Axis CNC Machining:

The most advanced form of aluminum cnc machining involves simultaneous movement along five axes, enabling the machining of intricate curves and undercuts in a single setup. This reduces handling errors and shortens lead times for highly complex parts.Key Challenges in Aluminum CNC Machining

Despite its advantages, cnc aluminum machining presents challenges that require careful management:Thermal Expansion

Aluminum’s high thermal conductivity can cause expansion or part deformation during machining aluminum. Maintain precise temperature control and use coolant to dissipate heat to solve the problem.Chip Evacuation

Aluminum produces long, stringy chips that can clog tools during cnc machining aluminum. Employ 2-3 flute tools to improve chip clearance and prevent jamming.Tool Adhesion (Built-Up Edge)

Aluminum’s softness causes material to stick to the cutting edges, reducing tool life and surface finish quality. Using coated carbide tools with the right cutting parameters mitigates this.Softness Surface

Aluminum’s softness can lead to burring or galling, impacting surface quality in CNC aluminium. Optimize cutting speeds and feed rates to minimize defects.Aluminum CNC Machining Applications

CNC machine aluminium parts are found across numerous industries:

- Aerospace: Lightweight structural components, brackets, housings, and engine parts.

- Automotive: Aluminum parts for engines, chassis, and bodywork.

- Medical: Surgical instruments, implant components, and device housings.

- Electronics: Heat sinks, casings, and connectors.

- Industrial Equipment: Tooling, jigs, molds, and custom automation components.

- Construction: Structural elements like beams and supports.

- Agriculture: Gearbox housings and hydraulic components.

Choosing the Right Partner for Aluminum CNC Machining

There are some considerations when to choose the right partner for aluminum CNC machining. Prioritize providers with advanced 5-axis CNC machines, experienced engineers, and robust quality control systems, such as ISO9001 certification, to ensure high-quality CNC aluminum parts. If you’re working on early-stage development, it’s important to choose a partner experienced in providing reliable prototype machining services to accelerate your design validation and functional testing. Fast turnaround times and expertise in aluminium machining will streamline your project from prototype to production. For professional CNC machining aluminum solutions, contact Zhongde.FAQs of Aluminum CNC Machining

Typical tolerances for CNC aluminum parts range from ±0.005 to ±0.001 inches, depending on the machine and design requirements.