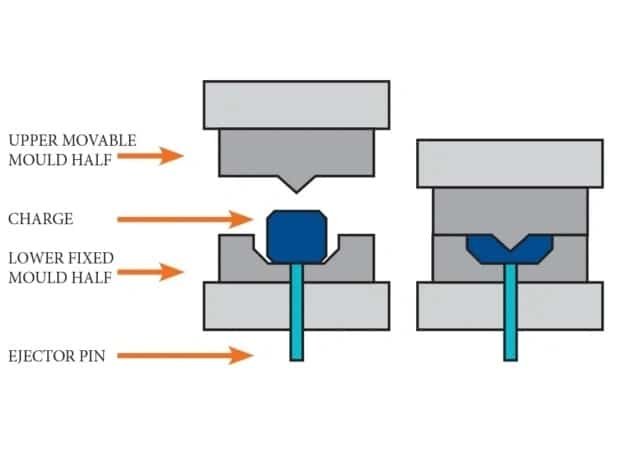

Compression molding services have been a trusted manufacturing method since the mid-19th century, initially used for custom rubber products and now widely applied to both rubber and plastic components. The compression molding process involves placing the material into a heated custom mold, where it’s softened, shaped, and then compressed into position by hydraulic presses. After curing, the part hardens and cools, ensuring its structural integrity.

While types of compression molding are ideal for producing larger, bulky parts, they may not be the best solution for all applications due to limitations in design complexity and material requirements. In the following, Zhongde will explore the key rubber and plastic advantages and disadvantages of compression molding to help you determine if it’s the right choice for your project. You can also learn more about common compression molding defects to better understand the process.

Advantages of Compression Molding Service

- Low Material Waste: Compression molding typically results in only 2% to 5% material loss, making it a more cost-effective molding method than others.

- Stable Mechanical Properties: Products have low internal stress and minimal warping, ensuring durable and consistent performance.

- Low Mold Maintenance Costs: Compression molding molds experience minimal wear, reducing maintenance costs and extending mold life.

- Cost-Effective Equipment: The equipment for compression molding is less expensive, with simpler molds, reducing overall manufacturing costs.

- Ideal for Larger Flat Parts: Suitable for molding larger parts, limited only by machine clamping force and template size.

- Good Dimensional Accuracy: Compression molding offers low shrinkage and high repeatability, ensuring consistent product quality.

- High Efficiency and Automation: The process is well-suited for automated feeding and product extraction, boosting production efficiency.

- High-Quality Finish: Compression molded products have smooth surfaces with no need for secondary processing.

- Complex Shapes: Capable of producing intricate parts in a single step, making it suitable for mass production at low costs.

Disadvantages of Compression Molding Service

- Longer Cycle Time: The molding cycle is longer than some alternatives, reducing overall production efficiency.

- Limitations for Complex Designs: It’s not ideal for parts with intricate features like dents or small holes, as mold filling may be incomplete.

- Challenges in Mold Filling: Achieving full mold cavity fill can be technically challenging, requiring precise control over material flow.

- Hardness Variability: Post-curing, products may have inconsistent hardness, which can affect their performance.

- Precision Limitations: For products requiring high precision (especially multi-cavity molds), compression molding may not meet exact tolerance standards.

- Flash Removal: Excess flash around the product can require extensive trimming, increasing labor costs.

- High Mold Investment: Although the process is straightforward, the initial investment in mold manufacturing is high, making it better suited for medium to small-scale production runs.

When Is Compression Molding the Right Choice?

Compression molding process is ideal for medium to large parts, simple to moderately complex shapes, and durable materials like rubber or thermosets. It works best for low to medium volumes where cost control and reliable strength are priorities.

Conclusion with Compression Moulding

Looking for a reliable compression molding partner? Zhongde provides custom rubber molding solutions tailored to your needs, delivering high-quality rubber products that meet diverse application requirements. Contact us today.

FAQs

Compression molding can be used with a variety of rubber and plastic materials. Common rubber types include EPDM, NBR, silicone, and natural rubber. The choice depends on the required mechanical properties, temperature resistance, and chemical compatibility.

Compression molding is commonly used to produce automotive parts (gaskets, seals, bumpers), electrical components (insulators, connectors), industrial goods (hoses, dampers), and consumer products (handles, appliance parts).

- Compression molding: better for large, simple, or heat-resistant rubber/plastic parts, lower material waste, and slower cycle times.

- Injection molding: better for highly detailed, complex parts, faster production, and higher mold cost.

Choosing the right process depends on design complexity, material, and production volume.