In rubber and thermoset manufacturing, transfer molding and compression molding stand out as two of the most widely applied methods. Both are effective for producing durable, heat-resistant, and dimensionally stable rubber products, yet they differ significantly in operation, cost, and design flexibility.

What Is Compression Molding?

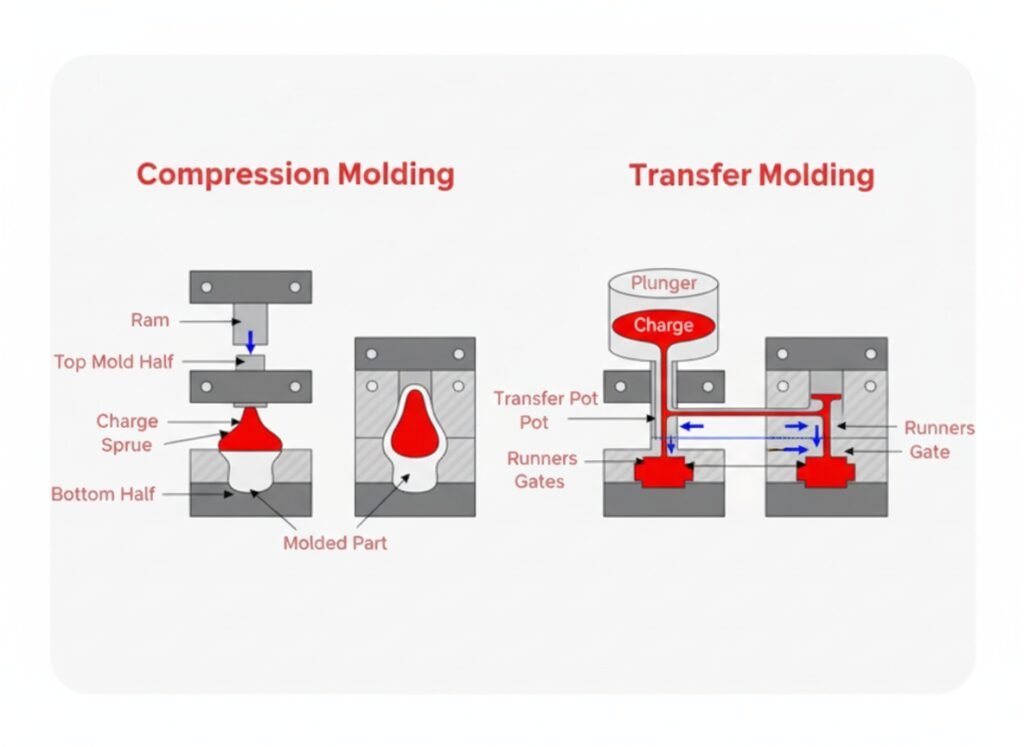

Compression molding applies heat and pressure to shape materials. In this process, a pre-measured amount of material, usually a preform or sheet, is placed directly into an open, heated mold cavity. Once the mold is closed, pressure and heat are applied simultaneously, causing the material to flow and fill the cavity. The material cures under pressure until the final solid shape is formed, after which the mold is opened and the part is removed.

Advantages and Disadvantages of Compression Molding

Compression molding offers several advantages, most notably its ability to process a wide range of thermoset and elastomer materials with excellent mechanical strength. The process requires relatively inexpensive tooling, and molds can be designed quickly compared to injection or transfer systems. Moreover, compression molding provides consistent material density, resulting in parts with strong structural integrity.

However, this process struggles with intricate geometries involving sharp angles or fine details, experiences extended cycle times of several minutes compared to faster alternatives, requires manual removal of flash and burrs that increases labor costs and waste, and demands precise charge measurement in some mold types to avoid defects.

Materials Used in Compression Molding

| Material Type | Key Properties | Common Applications |

|---|---|---|

| Natural Rubber (NR) | High elasticity, wear-resistant, low temperature performance | Seals, gaskets, vibration dampers |

| Nitrile Rubber (NBR) | Oil-resistant, fuel-resistant, wear-resistant | Oil seals, O-rings, hydraulic components |

| Silicone Rubber (VMQ / LSR) | High temperature stability, excellent weather resistance, soft touch | Medical devices, electronic seals, food contact parts |

| Fluoroelastomer (FKM / Viton) | High temperature resistance, chemical resistance | High-temp seals, automotive and aerospace components |

| Butyl Rubber (IIR) | Excellent gas barrier, chemical resistance | Airtight seals, soundproof gaskets |

| Polyurethane (PU / TPU) | High wear resistance, strong tensile strength, oil resistance | Gears, wheels, mechanical cushioning parts |

| Phenolic Resin (PF) | High hardness, electrical insulation | Electrical insulation parts, structural components |

| Epoxy Resin (EP) | High strength, chemical resistance | Electrical components, composite molds |

| Phenolic + Glass Fiber Composite | High strength, heat resistance, wear resistance | Industrial machinery parts, automotive components |

Mold Materials for Compression Molding

- Carbon Tool Steel: High hardness and wear resistance, suitable for standard molds.

- Alloy Tool Steel: High heat and impact resistance, ideal for high-frequency or large-volume production.

- Stainless Steel: Corrosion-resistant, used for molds with special material or clean requirements.

- Aluminum Alloy: Lightweight and fast to machine, suitable for prototypes or small batches.

- Copper / Copper-Nickel Alloy: Excellent thermal conductivity, used for quick-cooling areas.

- Surface-Treated Steel: Increased surface hardness and wear resistance, extends mold life.

Compression Molding Applications

Compression molding produces various components across industries.

- Automotive: Large panels and interior elements.

- Electronic: Keypads and controllers.

- Kitchenware: Plates and bowls.

- Electrical: Plugs, switches, and faceplates.

- Medica: Syringe stoppers and masks.

What Is Transfer Molding?

Transfer molding is a process that combines elements of both compression and injection molding. In this method, a preheated material is placed into a chamber—called a pot—separate from the mold cavity. A plunger then forces the material through runners or sprues into the closed mold cavities. The material fills the cavities under pressure and cures into the final shape. It is often used for components that include inserts, such as metal contacts or bushings, which must be accurately positioned before molding.

Advantages and Disadvantages of Transfer Molding

Transfer molding provides greater accuracy, improved surface finish, and reduced flash compared with compression molding. Because the material is transferred through a controlled channel system, it fills intricate cavities more efficiently and ensures consistent part quality. This makes transfer molding highly suitable for complex or multi-cavity molds.

However, these advantages come with higher tooling complexity and cost. The mold design must incorporate runners, sprues, and a transfer pot, which increases manufacturing time and expense. In addition, cleaning the mold between cycles can be more demanding due to potential residue in the transfer system.

Materials Used in Transfer Molding

| Material Type | Key Properties | Common Applications |

|---|---|---|

| Epoxy Resin | High strength, good electrical insulation | Electronic components, electrical parts |

| Phenolic Resin | Hard, heat-resistant | Structural and industrial parts |

| Polyester Resin | Chemical-resistant | Automotive and industrial applications |

| Silicone Rubber (LSR / VMQ) | Flexible, heat- and chemical-resistant | Seals, medical parts |

| Urethane (PU / TPU) | High wear resistance, elastic | Mechanical components, cushioning parts |

| Nitrile Rubber (NBR) | Oil- and fuel-resistant | Seals, gaskets |

| Fluoroelastomer (FKM / Viton) | High temperature and chemical resistance | Automotive and aerospace seals |

| Butyl Rubber (IIR) | Excellent gas barrier, chemical-resistant | Airtight seals, soundproof gaskets |

Mold Materials and Characteristics for Transfer Molding

- Carbon Tool Steel: High hardness and wear resistance, suitable for standard molds.

- Alloy Tool Steel: High heat and impact resistance, ideal for high-frequency or large-volume production.

- Stainless Steel: Corrosion-resistant, used for molds handling corrosive or clean materials.

- Aluminum Alloy: Lightweight and fast to machine, used for prototypes or small batches.

- Copper / Copper-Nickel Alloy: Excellent thermal conductivity, used for fast-cooling sections. 6. Surface-Treated Steel: Nitrided or carburized to increase surface hardness and wear resistance.

Applications of Transfer Molding

Transfer molding applies to industries requiring precise rubber or thermoset parts with inserts or complex features. Key uses include:

- Automotive parts: Grommets, bushings, and sensor encapsulations.

- Electrical Industry: Insulators, connectors, switchgear components, and encapsulated electronic parts.

- Medical components: Syringe plungers, valve seals, and device housings.

- Aerospace and defense: Seals and gaskets resistant to temperature extremes.

- Industrial equipment: O-rings, lip seals, and vibration mounts.

Transfer Molding and Compression Molding: Which One is Better for Your Project?

Selecting between transfer molding vs compression molding depends on project specifics.

Investment

Compression molding uses simpler, lower-pressure equipment and molds, reducing initial costs and setup time. Transfer molding requires more intricate tooling for the pot and runners, raising expenses, though the press itself costs less than high-volume alternatives.

Production Speed

Transfer molding completes cycles faster due to preform preparation and pressurized filling, often outperforming compression’s manual loading and longer dwell times under heat. Compression cycles extend to minutes, including post-ejection trimming.

Production volume

For medium to high production runs that require consistent quality, transfer molding offers better repeatability. Compression molding is ideal for low or medium volumes where tooling investment needs to remain economical.

Tolerance and precision

Transfer molding achieves higher dimensional accuracy and smoother surface finish due to its closed system and controlled pressure. Compression molding provides acceptable precision for less demanding parts but may produce more flash or variation.

Part complexity

Transfer molding is better suited for intricate or insert-laden parts because the material can flow through narrow channels to fill detailed cavities. Compression molding, by contrast, works best for simpler shapes with uniform wall thickness.

Amount of Waste

Compression molding generates controllable flash, minimizable with precise metering. Transfer molding creates more waste from pads, sprues, and overflow, unrecyclable in thermosets, increasing material losses.

Cost considerations

Compression molding remains more cost-effective for straightforward products and small batches. Transfer molding, while more expensive, justifies its cost when high precision and insert integration are required.

Zhongde Helps You to Choose

Compression and transfer molding deliver reliable results for rubber and composite parts. Our company, as a compression molding company, provides professional services to match your specifications. Contact us to discuss compression molding options and access high-quality services tailored to your project.