On-demand Manufacturing of

Power Transmission Molding

Home » Application » Transmission Device Custom Molding

Custom Parts for Power Transmission System Solution

Transmission systems handle power transfer, motion control, and overall efficiency. While most components are standard, certain applications need custom parts to meet specific performance, space, or durability requirements.

At Zhongde, we provide custom plastic and rubber, metal components for power transmission systems. Even for parts with very compact sizes or complex shapes, we can meet your design requirements. Share your needs with us, and we’ll deliver solutions tailored to your application.Custom Power Transmission Parts Manufacturing Capabilities

At Zhongde, our precision mold-making capabilities allow us to produce custom plastic and rubber components with very compact sizes and tight tolerances for transmisson parts.

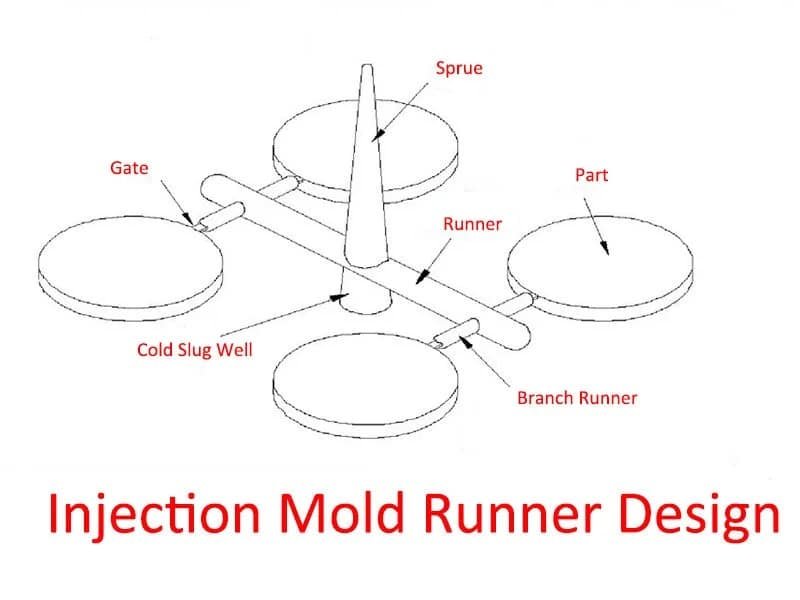

Custom Injection Molding Service

Zhongde has developed a one-stop solution from mold designing and rapid prototyping to mass production. We improve product accuracy and meet the custom requirements of complex-shaped parts.

Custom Compression Molding Service

We use high-strength, precision, heat-resistant metal molds to ensure product quality. Through compression molding, we achieve efficient production with precise, smooth-finished parts.

CNC Machining Service

Get custom CNC machining prototypes and production parts with high quality. We provide expert engineering reviews. Dozens of materials and finishes are available.

Cast Molding Service

Using cast molding, we produce small batches of accurate parts, following confirmed drawings or samples. Should any discrepancies occur, we make adjustments to ensure customer satisfaction.

Power Transmission Parts We Manufactured

No matter how small or compact your custom transmission components are, Zhongde can deliver high-quality solutions tailored to your needs.

- Bushings / Sleeves

- Gears / Gear inserts

- Couplings / Flexible joints

- Seals / Gaskets

- Dampers / Shock-absorbing pads

- Custom washers / Spacers

- Guides / Slides

Material Used in Power Transmission Parts

We select materials tailored to the specific mechanical requirements of your transmission machinery components. Whether you need high wear resistance, low friction, impact absorption, or dimensional precision, zhongde provides custom material solutions.

Rubber & Elementor

- EPDM

- NBR

- TPU

Plastic Materials

- PA

- POM

- HDPE

- UHMW-PE

Metal Materials

- Stainless Steel

- Aluminum

- Copper / Brass

Put Your Transmission Components into Production Now!

Our sales team will contact you within 24 hours. We are glad to answer your questions。

Your Partnership in Transmission Component Manufacturing

Industry Expertise

Decases of industry expertise in injection molding, delivering high-quality parts with precision and reliability. Trust our experience for your project's success

Flexible Customization

We offer customized solutions tailored to your unique injection molding needs. Our flexible approach ensures we can accommodate design modifications, material preferences, and production requirements with ease.

Collaorative Approach

We believe in a collaborative approach, working closely with our clients to understand their specific requirements and goals. Together, we achieve successful outcomes through effective communication and shared expertise.

Custom Transmission Parts is Faster with Zhongde!

Very considerate service, many problems encountered during the order process, their sales staff can alwavs reply to me in the first time, and provide effective solutions.

Zhongde' s engineers are very professional. When l have doubts about my customized products, they put forward some suggestions for improvement on the material and design of the products, which helped me to improve my design.

Reliable supplier. Although we have time lag. they can always solve any problems for me in time. And they can provide customized all kinds of spare parts we want, very convenient.

Very professional manufacturer. Our production was ofter halted because the previous manufacturer can not meet increasing demand. Then their engineers came up with new designs for our products and solved our problems.