Transfer molding and injection molding are two widely used manufacturing methods, each with distinct processes, material compatibility, and typical applications. This article explores the key differences, advantages, and limitations of transfer molding and injection molding, providing a clear overview of their respective strengths and suitable applications.

What is Injection Molding?

Injection molding is a plastic manufacturing process used to produce parts by injecting molten material into a mold cavity. It is one of the most widely used processes for manufacturing plastic parts due to its versatility, efficiency, and ability to produce high volumes of parts with high precision and complexity. For a more detailed overview, you can refer to our guide on injection molding basics.

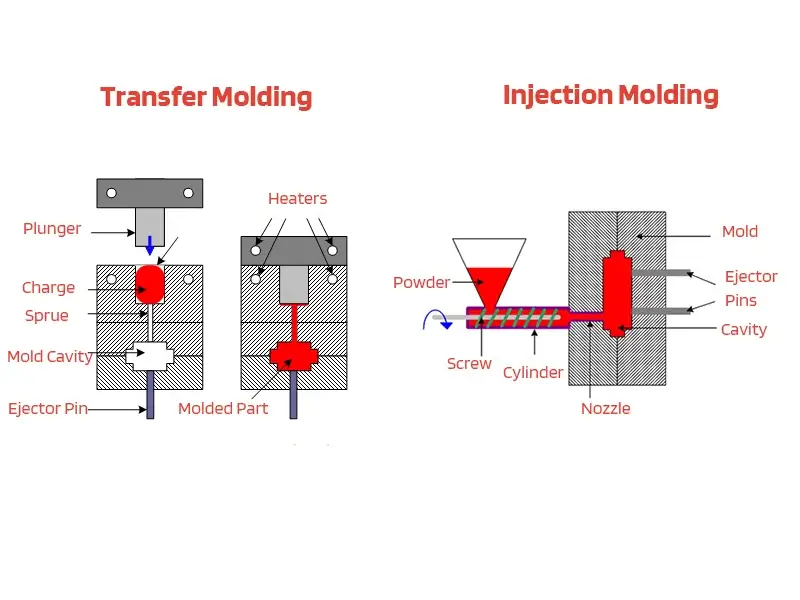

The Injection Molding Process

- Mold Design: The process begins with the design of the mold, which is typically made from steel or aluminum. The mold consists of two halves: the cavity (the negative of the part) and the core (the positive of the part), injection system(sprue, runners, gates), cooling system, ejection system, vent system, clamping system, etc.

- Material Preparation: Thermoplastic or thermosetting plastic pellets are fed into a hopper and melted using heating elements within a barrel of an injection molding machine. The molten material is then injected into a mold cavity under high pressure.

- Injection: Once the material reaches the desired temperature and consistency, a reciprocating screw or plunger forces the molten material through a nozzle into the mold cavity. The injection pressure ensures that the material completely fills the cavity and takes on the shape of the mold.

- Cooling: After the mold cavity is filled, the molten material is allowed to cool and solidify within the mold. Cooling channels or other cooling methods are used to control the rate of cooling and ensure uniform solidification of the part.

- Ejection: Once the material has sufficiently cooled and solidified, the mold opens, and the finished part is ejected from the mold cavity using ejector pins or other mechanisms. Any excess material, known as flash, may be trimmed off to achieve the desired final dimensions.

Injection Molding Advantages

- High Efficiency: Injection molding is highly automated and can produce large volumes of parts with minimal labor input, leading to high production efficiency.

- Complex Geometries: The process allows for the production of parts with intricate shapes, thin walls, and complex features that may be difficult or impossible to achieve using other manufacturing methods.

- High Precision: Injection molding offers tight tolerances and excellent repeatability, resulting in parts with consistent dimensions and quality.

- Wide Range of Materials: Injection molding can accommodate a wide variety of thermoplastic and thermosetting materials, allowing for versatility in material selection to meet specific performance requirements.

Injection Molding Disadvantages

- High Initial Investment: Setting up an injection molding operation requires significant upfront investment in machinery, molds, and infrastructure. The cost of molds, in particular, can be substantial, especially for complex or multi-cavity molds.

- Long Lead Time for Tooling: Designing and fabricating molds for injection molding can take weeks to months, depending on complexity and customization requirements. This lead time can delay the start of production and impact time-to-market for new products.

- Limited Flexibility for Small Production Runs: Injection molding isn’t suitable for low-volume production due to high initial setup costs.

- Design Limitations: Certain design features, such as undercuts or thin walls, may be challenging to mold using traditional injection molding techniques. Specialized tooling or secondary operations may be required to accommodate these design elements.

Injection Molding Applications:

Injection molding is widely used across automotive, consumer electronics, and industrial sectors to produce high-precision components such as car interior panels, smartphone housings, connectors, and complex machinery parts.

What is Transfer Molding?

Transfer molding is a manufacturing process used to produce plastic or rubber parts by forcing preheated uncured material into a mold cavity. It is widely used for manufacturing parts that require high precision, intricate details, and consistent quality.

The Transfer Molding Process

- Material Preparation: The raw material, often in the form of pellets, sheets, or preforms, is preheated to a specific temperature to make it more fluid and easier to transfer into the mold cavity.

- Mold Design: The mold for transfer molding typically consists of multiple parts: the pot, the transfer plunger, the mold cavity, and sometimes a runner system.

- Transfer Process: The preheated material is loaded into a chamber or pot, which is positioned above the mold cavity. Pressure is applied to force the material into the cavity through the runner system, ensuring complete filling of the mold.

- Curing: After the material fills the mold cavity, it undergoes curing to solidify and take the shape of the mold. Curing may involve the application of heat, pressure, or chemical reactions, depending on the type of material used.

- Part Removal: Once the material has cured and solidified, the mold is opened, and the finished part is removed. Any excess material, known as flash, may be trimmed off to achieve the desired final dimensions.

Advantages of Transfer Molding:

- Lower Equipment Costs: Transfer molding machines and tooling are generally more affordable, making it a cost-effective choice for small to medium production runs.

- Insert Compatibility: Transfer molding easily accommodates inserts or metal components, allowing the production of parts with embedded features.

- High Precision and Detail: Transfer molding enables sharp edges, fine details, and tight tolerances, producing high-quality, precise components.

- Multiple Cavities: Transfer molding allows for the use of multiple cavities, which increases production output per cycle and improves efficiency.

Disadvantages of Transfer Molding:

- Low Volume Production: Transfer molding is better suited for small to medium batches rather than very high-volume production.

- Material Wastage: Excess material from sprues, runners, and overflow grooves can lead to higher material usage.

- Slower Production Rates: Preheating materials and longer cycle times make the process slower.

- Part Complexity Limitations: Extremely intricate geometries or very thin walls can be challenging to achieve with transfer molding.

- Higher Maintenance Costs: Molds require regular maintenance due to their complexity, which can increase long-term operating costs.

Transfer Molding Applications:

Transfer molding is commonly used across automotive, electronics, and industrial sectors to produce high-performance components such as car door seals, dashboard gaskets, electrical connectors, and precision machinery parts.

Key Differences of Transfer Molding and Injection Molding

There are several key different aspects between transfer molding and injection molding.

| Aspect | Transfer Molding | Injection Molding |

|---|---|---|

| Working Process | Material is preheated and transferred into the mold cavity | Raw material pellets are melted and injected into the mold cavity |

| Production Volume | Low to medium volumes | High volumes |

| Production Speed/Efficiency | Slower compared to injection molding | Typically ranging from 2 seconds to 2 minutes per cycle |

| Precision and Tolerances | Good precision and tight tolerances | Excellent precision and tight tolerances |

| Materials | Epoxy, PF Plastic | PP, PA, PVC, Liquid Silicone Rubber, ABS |

| Different Equipment | Transfer Molding Machine | Injection Molding Machine |

| Applications | Electronics, automotive, and industrial | Automotive, consumer goods, medical devices, packaging |

| Part Complexity | Sharper edges and integrated inserts | Larger, thin-walled parts |

| Initial Investment | Low initial investment | Higher initial investment |

Transfer Molding and Injection Molding, Which One Is Better for Your Project?

When deciding between transfer molding and injection molding for your project, there are several key factors to consider:

Production Volume

Injection molding is better suited for high-volume production runs due to its faster cycle times and higher levels of automation. Transfer molding is more suitable for lower-volume production.

Part Size and Complexity

Injection molding can produce larger and more complex parts with thin walls, while transfer molding is limited to smaller and simpler part geometries. Injection molding struggles with sharp edges, whereas transfer molding can create well-defined edges and corners.

Initial Investment

The initial investment for injection molding machinery and tooling is significantly higher than for transfer molding equipment. However, injection molding offers lower labor costs in the long run due to higher automation levels.

Material Waste

Transfer molding generates more material waste from sprues, air holes, and overflow grooves compared to injection molding. This can increase costs for thermosetting materials.

Precision and Surface Finish

Both processes can achieve high precision, but injection molding generally provides better dimensional accuracy and surface finish quality.

In summary, if your project requires high-volume production of larger, complex parts with tight tolerances, injection molding would likely be the better choice despite higher upfront costs. However, for lower volumes of smaller, simpler parts with well-defined edges, transfer molding may be more cost-effective due to lower tooling complexity.

Conclusion

Both transfer molding and injection molding offer unique advantages depending on the application and production requirements. Zhongde focuses on high-quality custom molding services and provides a wide range of custom molded parts to meet diverse industry needs. With expertise in mold design, material selection, and precision manufacturing, we deliver reliable solutions tailored to each project. Contact Zhongde today to explore how our expertise can support your next project.