Thermoplastic polyurethane (TPU) injection molding is a vital process in manufacturing flexible, durable, and high-performance plastic parts. As a versatile elastomer, TPU combines the benefits of rubber-like elasticity with thermoplastic processability. As a popular material for customized injection molding, TPU is frequently chosen. This article explores the TPU injection molding process in detail.

TPU Injection Molding Service

TPU Properties: Advantages and Disadvantages

What Is the Advantages of Tpu Material?

Elastic and Flexible: TPU offers rubber-like elasticity with excellent flexibility, making it suitable for parts that require bending, stretching, or dynamic movement.

Abrasion and Wear Resistant: Known for its toughness, TPU performs well in high-friction environments and maintains integrity under repeated mechanical stress.

Chemical and Oil Resistance: It resists common industrial substances such as oils, greases, fuels, and solvents, making it ideal for automotive and machinery applications.

UV and Weather Resistance: TPU withstands outdoor conditions, including sunlight, ozone, and moisture, without significant degradation over time.

Low Temperature Performance: Remains flexible and durable even at temperatures as low as -40°C, making it reliable for cold-weather or refrigerated environments.

Hardness Versatility: Available in a broad range of hardness grades (Shore A to Shore D), allowing customization based on impact, flexibility, or rigidity needs.

Processing Compatibility: TPU supports multiple manufacturing methods such as injection molding, extrusion, and blow molding, offering design freedom and scalability.

What Is the Disadvantages of Tpu Material?

Processing Complexity: TPU requires precise control of processing parameters such as temperature, pressure, and drying time. It is more challenging than processing standard thermoplastics.

Higher Material Cost: Compared to common plastics, TPU is more expensive, which can limit its use in cost-sensitive applications.

Moisture Sensitivity: TPU is hygroscopic and absorbs moisture from the environment. This requires thorough drying before processing to prevent , voids, and surface defects during the TPU injection molding process.

Adhesion Challenges: Bonding TPU to metals or rigid plastics often requires specialized adhesion agents or surface treatments, adding complexity to manufacturing.

Limited Chemical Resistance: While resistant to many chemicals, TPU is vulnerable to certain solvents like ketones and esters.

Aging Over Time: TPU may experience reduced elasticity and mechanical strength over time affecting long-term performance.

Surface Finish: TPU typically has a matte finish, which may not suit applications requiring a glossy appearance.

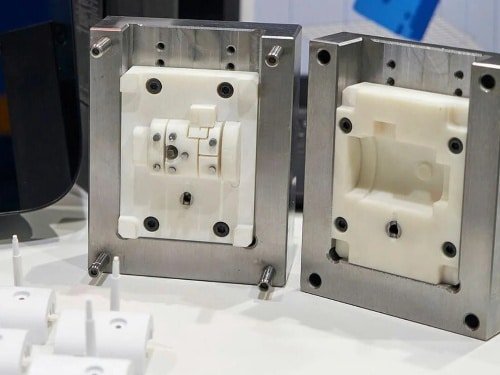

Mold Design Considerations for TPU Molding

Effective mold design is critical for successful TPU molding as TPU’s unique properties. Below are key considerations for optimizing mold design, tailored to TPU’s characteristics:

- Gate Design: Use a large gate, the diameter not exceeding the product’s wall thickness, to ensure smooth material flow and minimize shear stress. Keep the sprue as short as possible to reduce material waste and pressure loss during injection.

- Shrinkage Compensation: TPU typically exhibits a shrinkage rate of 1–3% in the flow direction. For common products, design molds with a shrinkage allowance of 0.5–0.6%.

- Mold Surface Roughness: Maintain a surface roughness of 25–35 mm. Overly polished surfaces can increase sticking.

- Runner System: Implement a balanced runner system with a rounded cross-section to ensure even material distribution and minimize pressure drops.

- Exhaust Slots: Incorporate exhaust slots of 0.015–0.03 mm to allow trapped air to escape.

- Demolding Angle: Use a draft angle of 5° to facilitate easy part ejection as TPU’s tackiness.

- Wall Thickness: Maintain uniform wall thickness, 1–2 mm for softer TPU grades, 2–3 mm for harder grades.

TPU Injection Molding Process Steps

The tpu injection molding process consists of several sequential steps:

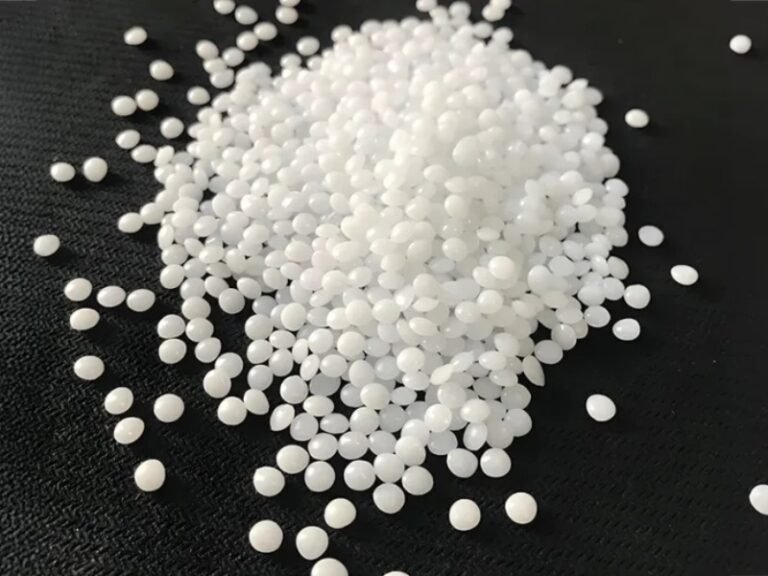

- Material Preparation: Dry TPU pellets thoroughly to eliminate moisture.

- Feeding and Plasticizing: Load dried pellets into the injection molding machine, where they are melted at controlled temperatures.

- Injection: Inject molten TPU into the mold cavity under high pressure.

- Cooling: Maintain mold temperature to solidify the part.

- Ejection: Open the mold and eject the finished part carefully.

TPU Molding Conditions

The TPU injection molding process hinges on precise control of processing conditions to achieve optimal results. Key parameters include:

- Melt Temperature: Maintain 180–230°C to ensure proper flow without degrading TPU.

- Mold Temperature: Set at 15–60°C, adjusted for TPU hardness and part size.

- Injection Speed: Use medium speeds (20–80 rpm screw speed) to avoid internal stresses or air entrapment, which can cause bubbles.

- Drying: TPU pellets must be dried at 80–110°C for 2–4 hours to reduce moisture below 0.02%, preventing bubbles and surface defects.

- Injection Pressure: Usually 200–600 psi, adjusted to fill the mold completely without causing flash.

- Cooling Time: Depending on part thickness, generally allow 40–60 seconds to ensure solidification.

Typical TPU Injection Molded Parts

Automotive: Seals, gaskets, cable jackets, soft-touch interior components

Consumer Electronics: Protective cases, wearable device straps, cable insulation

Medical: Catheters, tubing, flexible housings

Footwear: Outsoles, midsoles, cushioning pads

Industrial: Hoses, conveyor belts, gaskets, wheels

Sports Equipment: Protective gear, grips, flexible components

Challenges and Solutions in TPU Molding

TPU molding presents challenges such as sticking to molds, shrinkage variability, surface defects, and adhesion issues in overmolding. These can be addressed by using mold release agents, maintaining mold temperatures between 15–60°C, incorporating draft angles, ensuring proper drying (<0.02% moisture), and selecting compatible substrates with surface treatment to improve bonding.

Cooperate with Zhongde

Although there are many challenges in TPU injection molding, working with a professional custom injection molding company can help resolve them efficiently. Zhongde with deep expertise in TPU molding, advanced equipment for precise control, and a proven track record of delivering high-quality, defect-free parts across industries like automotive, medical, and consumer electronics.

FAQ

TPU hardness, measured by Shore A (soft grades) or Shore D (hard grades), ranges roughly from 60A to 80D. Higher TPU hardness means stronger and more rigid parts but less flexible.

Use proper ventilation to avoid fumes, wear protective gear, dry the material well, and maintain equipment to keep operators safe and ensure quality.

Precise temperature (180–230°C melt, 15–60°C mold) ensures proper flow and solidification, while proper pressure prevents defects like bubbles or stresses. Incorrect settings can cause warpage, incomplete filling, or material degradation.

TPU resists UV light, ozone, and many chemicals (oils, greases). However, it’s vulnerable to ketones, esters and may lose elasticity in extreme heat or cold over time.