What is Rubber Molding?

The production of rubber items typically involves the molding process, which utilizes a metal mold to transform raw rubber into products. The molding process involves filling a mold cavity with rubber, heating, and pressing the material to create the desired shape. This method is widely used in the manufacturing industry as it allows for the fast and efficient creation of high-quality components with accurate proportions and exceptional mechanical properties, all at a cost-effective price and in a shorter time frame compared to alternative techniques.

Which Rubber Molding Process Is Right for You?

Selecting the right molding process is a critical step in rubber product development. The choice directly impacts cost, quality, and long-term performance. Different projects may call for different methods, and understanding the strengths of each process helps ensure the best fit for your application.

Cost of Custom Rubber Molded Parts

For effective custom rubber molding, selecting the appropriate rubber material is of the utmost importance. The elastomer selection process might be complicated, but our staff has the expertise to guide clients in making the best choice. The cost of the custom rubber molded parts varies; you need to gauge it as per your requirements and needs.

Rubber Material Selection

Types of Rubber Molding Processes

Rubber Injection Molding

In the mid-1960s, a method initially utilized for the injection molding of plastics was adapted for rubber. Unlike plastic injection molding, which requires lower pressure per square inch of cavity surface and temperature, rubber injection moluding process involves heating the rubber and applying greater pressure. Thanks to advancements in technology, rubber injection moulding has evolved into a highly effective method for producing molded rubber items.

With this method, a completed product of superior quality can be achieved, even when using higher temperatures and greater pressure. Material preparation is the first step in both injection and transfer molding. The compounded rubber is cut into uniform strips and fed into the screw inside the heated barrel, which advances it into the mold.

Advantages of Rubber Injection Molding

- Lessening of per-unit expenditures

- Minimized cycle times

- Very tight tolerances in all dimensions

Disadvantages of Rubber Injection Molding

- The more expensive initial investment

- It’s possible to waste material

- Increase in need for high-priced equipment

Rubber Compression Molding

Compression molding service is a method for producing molds, also known as “pre-forms,” from a rubber compound or other raw material blend. These pre-forms come with an excess material that is used to ensure a complete fill of the cavity. The mold is then closed around the pre-form, and heat and pressure are applied to press the material into the cavity. Any excess pre-form material flows out through overflow channels. The final molded rubber product is revealed upon demolding, which is usually done by hand. This method of rubber molding is commonly used for medium hardness compounds, low-volume production, and other situations where material cost is a major factor. Compression molding reduces waste or “flash” during the molding process.

Advantages of Rubber Compression Molding

- A less complicated procedure.

- There will be less money spent on tools.

- It’s perfect for making bulky objects and sturdy components.

Disadvantages of Rubber Compression Molding

- There is a lag in processing times.

- It can’t handle all intricate patterns.

- The possibilities of additional post-molding expenses are increased.

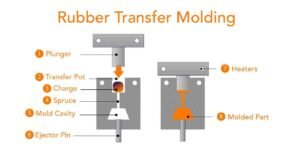

Rubber Transfer Molding

The molding material is measured, inserted, and put in the molding pot before the process begins. The material is transferred into the mold cavities by heat and pressure as it is heated.

The composite seal may be made with various inserts, including plastic and metal. These provide a multi-component sealing solution, which provides a more durable seal and helps minimize the total component count in assembly.

Advantages of Rubber Transfer Molding

- It has a brief production cycle

- There is a variety of design flexibility

- It offers a large count of cavities

Disadvantages of Rubber Transfer Molding

- There are complex molds

- You have to take care of mold maintenance

- There remains waste material

Applications of Different Rubber Molding Types

Rubber Compression molding: large seals and gaskets, rubber pads, bushings, bellows.

Rubber Transfer molding: electrical connectors, encapsulated parts with inserts, complex-shaped seals, medical components.

Rubber Injection molding: O-rings, precision gaskets, vibration mounts, automotive parts, consumer product components.

Start Your Rubber Moulding Process with Zhongde

Are you seeking the most amazing rubber molding services? Zhongde is driven by a desire to assist businesses across industries in meeting the demands of their customers via the provision of bespoke, long-lasting goods at reduced costs. Our goal is to provide premium goods at record speed.