When developing a new plastic product, one of the most critical steps is plastic prototype manufacturing. Maybe you have these questions?

- What is a plastic prototype?

- Why do plastic prototype manufacturing?

- Which type fits the project stage?

- How does testing ensure functionality?

- Why do plastic prototype manufacturing?

Early models expose flaws before production and address these defects to reduce risks and costs. Zhongde provides professional plastic proteotype manufacturing and meet the requirements from plastic prototypes to mass production.

What is a Plastic Prototype?

A plastic prototype serves as an initial model to evaluate size, shape, form, fit, and function before mass production. Plastic prototypes range from basic visuals to near-production quality. It bridges the gap between concept design and mass manufacturing.

Visual/Tactile Prototypes: These focus on appearance and dimensions without functionality. Testing occurs in early Engineering Validation Testing (EVT) to check basic form. SLA or FDM methods produce them quickly at low cost.

Functional Prototypes: These use materials close to production for initial performance checks. Design Validation Testing (DVT) assesses usability and reliability. CNC or SLS works well to reveal interaction issues.

High-Resolution Prototypes: These mimic final parts for full fit and function. Production Validation Testing (PVT) verifies consistent quality.

The three testing phases include:

- EVT for basic engineering functionality.

- DVT for full design usability and compliance.

- PVT for production line stability and first-article inspection.

How to Create a Plastic Prototype?

There are several methods available for plastic prototype manufacturing, each with its unique advantages. Choosing the right one depends on design complexity, quantity, budget, and timeline.

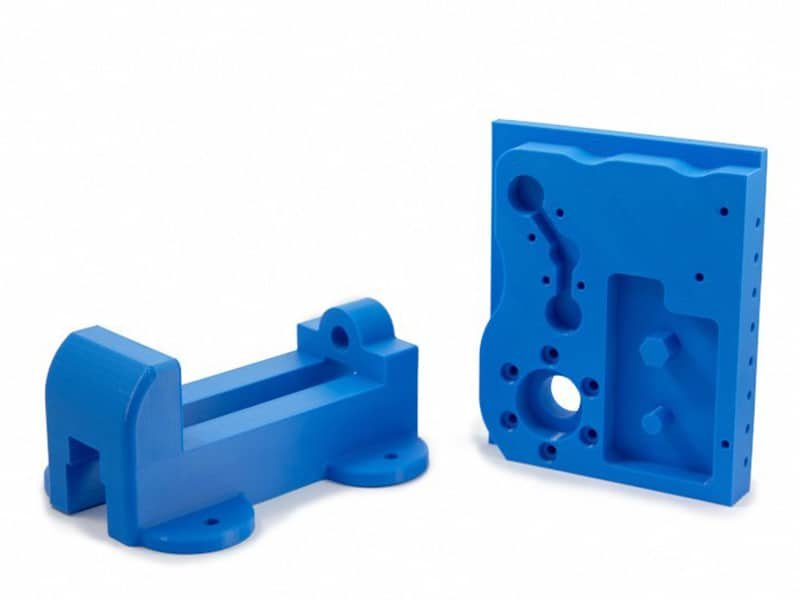

CNC Plastic Prototype

CNC machining is a highly precise and reliable method for producing rapid plastic prototypes. Guided by CAD data, the process removes material from solid blocks to achieve tight tolerances and smooth surfaces without layer lines. It supports various engineering-grade thermoplastics such as ABS, PC, POM, PP, and Nylon, enabling accurate testing of real mechanical properties. Key advantages include consistent strength and minimal post-processing, while limitations involve higher material waste and restrictions on complex organic shapes.

CNC Plastic Prototype

3D Printing (Additive Manufacturing)

3D printing adds layers via FDM, SLA, or SLS for complex geometries. It builds parts layer by layer directly from CAD data, eliminating the need for tooling. That makes the iteration in hours. SLS supports durable small batches. Benefits include no tooling and low waste. Drawbacks include lower strength, limited material selection for functional testing, and lower surface finish. Rapid prototype plastic methods like 3D printing accelerate early changes.

3D Printing Plastic Prototype

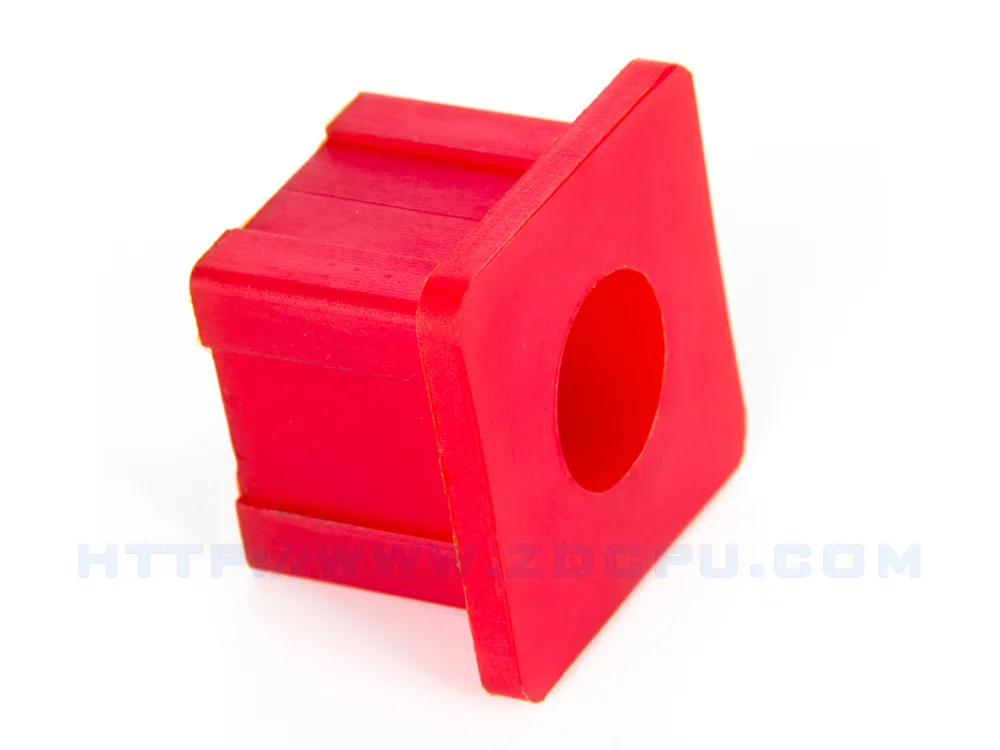

Vacuum Casting

Vacuum casting replicates from a 3D master in silicone molds under vacuum. The resulting parts closely resemble injection-molded products in appearance and texture. Benefits include accurate shapes and excellent surface quality at medium cost. It is suitable for marketing samples and appearance testing. Drawbacks limit mold life to 25 shots and fine details. This supports EVT with multiple variants.

Nylon Injection Molding Service

Prototype Plastic Injection Molding

Prototype plastic injection molding is the most accurate process for producing prototypes that truly represent mass-produced parts. Injection molding melts material into aluminum molds, then cooling and ejecting the part for 100+ units. Benefits cover cycle speed and identical quality. Drawbacks involve high mold costs. Prototype plastic injection molding prepares for PVT.

Learn more about plastic molding process.

Nylon Injection Molding Service

Comparison Table for The Plastic Prototyping Services

| Aspect | CNC | 3D Printing | Vacuum Casting | Injection Molding |

|---|---|---|---|---|

| Lead Time | 1-3 days | Hours-1 day | 7-10 days | 2-6 weeks |

| Precision | Tight/High | Medium/Medium | High/High | Tight/High |

| Cost | Medium/Medium | Low/High | Medium/Low | High/Low |

| Suitable Quantity | Medium | Low | Small | High |

| Suitable Stage | Functional Testing | Design Validation | Appearance & Marketing Samples | Pre-production & Pilot Runs |

Factors to Consider in Plastic Prototype Manufacturing

Before starting a prototype project, designers and engineers should consider several key factors that influence both performance and manufacturability.

Material Selection

When selecting materials, balance physical performance with processing requirements. Below is a comparison of commonly used materials in plastic prototype manufacturing:

| Material | CNC Machining | 3D Printing | Injection Molding | Vacuum Casting |

|---|---|---|---|---|

| ABS | X | X | X | |

| POM | X | X | ||

| PMMA | X | X | ||

| Nylon | X | X | X | |

| PC | X | X | ||

| PE | X | |||

| PEEK | X | X | ||

| PET | X | |||

| PLA | X | |||

| PP | X | X | ||

| PTFE | X | X | ||

| PVC | X | |||

| TPE | X |

Design Complexity and Tolerance

Complex shapes, undercuts, or thin walls may require special tooling or process optimization. Tolerance requirements also influence the method choice, CNC plastic prototype machining provides tighter tolerances, while 3D printing is more flexible for intricate geometries.

Surface Finish and Post-Processing

Surface treatments such as polishing, painting, sandblasting, or texturing help achieve desired aesthetics or tactile effects. Post-processing ensures prototypes not only perform well but also look close to production parts.

Cost and Lead Time

Each method has its trade-offs between cost and turnaround. Rapid prototyping companies help customers evaluate these factors early by offering DFM feedback and cost estimation.

Start Your Plastic Prototype Manufacturing Project

Partnering with professional plastic prototyping services manufacturer is the most efficient way to bring your concept to life. Zhongde provides comprehensive support from rapid prototype plastic design to prototype plastic injection molding, CNC machining, and vacuum casting. Ready to get started on your plastic prototyping project?