What is HDPE?

Advantages and Disadvantages of HDPE 3D Printing

HDPE plastic 3D printing comes with its strengths and challenges. Understanding these can help you decide if HDPE is right for your next project.Advantages of HDPE 3D Printing

High Strength-to-Weight Ratio: HDPE offers considerable tensile strength (typically 22-31 MPa) while remaining lightweight, ideal for parts where weight savings are crucial without sacrificing durability. Low Moisture Absorption: Less than 0.01% absorption maintains dimensional stability under humid or wet conditions. Flexibility and Impact Resistance: HDPE can endure repeated bending and mechanical shocks without cracking, useful for functional parts requiring toughness. Excellent Chemical Resistance: It withstands exposure to acids, bases, organic solvents, and other harsh chemicals, making it suitable for industrial and outdoor components. FDA Food Contact Approval: HDPE is safe for food-related applications such as containers, lids, and packaging components. Cost-Effective and Recyclable: HDPE raw materials are inexpensive and readily available. The material’s recyclability allows reuse of failed prints and scrap filament, supporting sustainable manufacturing practices. For complex shapes, plastic injection molding service is another effective solution.

HDPE 3D Printing Service

Disadvantages of HDPE 3D Printing

Warping and Shrinkage Issues: Due to high crystallinity, HDPE tends to warp and shrink during cooling, which complicates print accuracy and dimensional stability.

Poor Bed Adhesion: It has low surface energy, which leads to difficulties sticking to the print bed, often requiring specialized surfaces or adhesives.

High Printing Temperature Requirements: A heated nozzle and heated bed around 220–250°C are necessary, alongside often requiring an enclosed 3D printer to maintain a stable thermal environment.

Limited Filament Availability: Compared to popular filaments like PLA or ABS, hdpe 3d printer filament options are less common and can be pricier.

Surface Finish Challenges: HDPE’s natural low surface energy leads to slightly rougher or less glossy finishes compared to some other plastics unless extra post-processing is applied.

Precautions for Using HDPE in 3D Printing

Printing with HDPE requires particular attention to process control and environmental conditions:

- Demands a robust HDPE 3D printer with a hotend reaching 230–260°C and a heated bed at 100–130°C.

- Optimize Bed Adhesion. The low adhesion properties of HDPE call for additional measures. Apply polypropylene (PP) packing tape to the build surface, improving first-layer stability. Alternatively, use a raft or brim to anchor the print.

- Fine-Tune Temperature and Speed. Set your nozzle to 230–260°C, depending on the filament brand, and keep the bed at 100–130°C. A slow print speed of 20 mm/s reduces warping and ensures strong layer bonding.

- Manage Cooling Carefully. Unlike PLA, HDPE rapid cooling exacerbates shrinkage, weakening interlayer adhesion and causing cracks. Disable cooling fans or use minimal airflow, and let prints cool gradually in an enclosed chamber.

Alternatives to HDPE for 3D Printing

While HDPE holds many advantages, other materials are commonly used as substitutes based on ease of printing or different performance characteristics:

PETG: A polyethylene variant with glycol, PETG offers superior printability, flexibility, bed adhesion and less prone to warping.

ABS-HDPE Blends: Combining ABS with HDPE improves tensile strength and printability while retaining durability.

PLA: PLA prints easily and is widely available. However, it’s brittle and less heat-resistant.

PP: Like HDPE, PP resists chemicals and flexes well but adheres better to print beds.

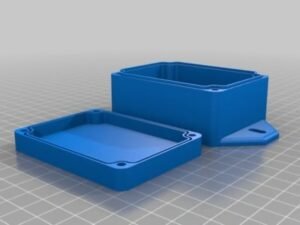

Applications of HDPE 3D Printing

The versatility of HDPE for 3D printing unlocks solutions across many sectors:

- Packaging Industry: Containers, lids, and beverage accessories.

- Automotive: Clips, mounts, bumpers, fuel tank .

- Outdoor Equipment: Outdoor fixtures, planters, pool toys, keychain buoys, fishing bobbers, and living hinges.

- Medical: Medical device housings or storage containers.

- Marine and Recreation: Small boat components, pool accessories, or water toys.

- Industrial: Pipes, fittings, or chemical containers.

- Consumer Goods: Custom household items, sporting goods, and toys.

- Furniture and Interior Design: Furniture parts, scaffolding, flooring, and decorative interior components.

Conclusion

Although challenges such as warping and adhesion remain, HDPE 3d printing represents a popssible of traditional material excellence and modern manufacturing innovation. Zhongde provides professional custom HDPE 3D printing service, as well as plastic injection molding service to meet a wide range of manufacturing needs. Welcome to contact and get a comprehensive solution for your project.