Have you ever wondered how some products feel soft in your hand yet remain strong and durable? Overmolding is the process that makes this possible. By combining rigid substrates with flexible materials like TPE, silicone, or rubber, overmolding creates parts with ergonomic grips, soft-touch surfaces, and improved resistance to wear and environmental conditions. As an advanced application of customized injection molding, this technique is widely used in automotive components, consumer electronics, and medical devices to simplify assembly, enhance product performance, and deliver high-quality results.

What is Overmolding?

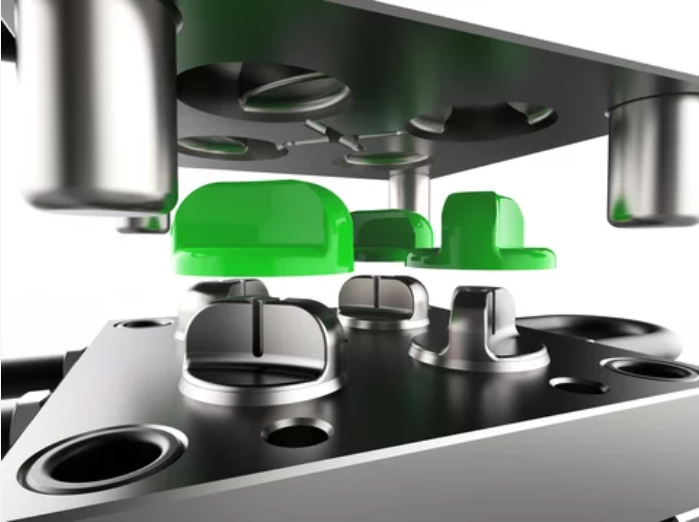

Overmolding is a manufacturing process that involves molding one material over another substrate to create a single integrated part. The process begins by placing a preformed material or substrate, such as a metal insert or plastic base, into a mold cavity. Then a second material, often thermoplastics, rubber, silicone, or TPU, is injected over the substrate to produce the final product.

Zhongde Overmolding Service

What Are Some Examples of Overmolding?

Overmolding can be used to add functional and aesthetic features to a product. For example, an overmolded handle on a tool can provide a comfortable grip, while an overmolded logo can provide a branding element.

Here are some common examples of overmolded objects to help you better understand what overmolding is and how it enhances functionality, grip, and durability in everyday products:

- A toothbrush with a soft rubber grip is an example of over-molding. The toothbrush handle, made of plastic, is the substrate material, and the soft rubber grip is the overmold material. The rubber grip is molded around the plastic handle to create a comfortable and ergonomic grip for the user.

- Another example of over-molding is the handle of a screwdriver. The substrate material is the metal shaft of the screwdriver, while the overmold material is a soft rubber or plastic grip. The overmolded grip provides a comfortable grip and improved control while using the screwdriver.

Types of Overmolding Processes

After understanding the basic steps of overmolding, it is important to know the main methods used in production. Overmolding can be carried out manually or with two-shot injection molding, each method offering different advantages in terms of cost, efficiency, and production volume.

Manual Overmolding

In this method, the substrate is first produced, usually through traditional injection molding. If the substrate is metal, it may be made by CNC machining. The operator then places the substrate into a second mold where the overmolding takes place. Afterward, the finished part is removed, inspected, and packaged. This method works well for low to medium production volumes, but cycle times can vary due to manual handling.

Two-Shot Injection Molding

This advanced method uses specialized injection molding machines that can process two materials within a single cycle. The mold first forms the substrate on one side, then automatically transfers it to another cavity where the second material is injected. Although two-shot molds and machines are more costly and complex, they allow consistent production and can reduce the cost per part compared with manual overmolding.

Overmolding by Material

Overmolding can be categorized based on the materials used, mainly into plastic overmolding and rubber overmolding. Each material type has its own process and common applications.

Plastic Overmolding

Plastic overmolding is closely related to plastic injection molding services, and it commonly uses materials such as ABS, PC, PP, PE, and TPU because they can be melted and reshaped multiple times without affecting their properties.

The process begins by placing a substrate, such as a metal or plastic component, into the mold cavity. The selected plastic is then injected over the substrate, filling the cavity around it, and allowed to cool and solidify before the finished part is removed from the mold.

Plastic overmolding is widely used to produce cable connectors, syringe housings, dashboard panels, and handheld device casings.

Rubber Overmolding

Rubber overmolding is part of comprehensive rubber molding services, and it typically uses materials such as natural rubber, silicone, elastomers, and EPDM because they provide flexibility, enhanced grip, and resistance to shock and chemicals.

In this process, the substrate is placed into a mold cavity, and liquid rubber is injected around it. The rubber is then cured with heat, and after cooling, the finished part is removed from the mold.

Rubber overmolding is commonly used for products like handles, grips, seals, gaskets, and other components.

Plastic and rubber overmolding can also be combined to create parts such as tool handles with soft grips, protective camera casings, and sealed switch covers.

How to Design an Overmold?

Several factors need to be considered when designing an overmold. The primary goal of these considerations is that the final product should meet the aesthetic, ergonomic, and functional requirements.

- Determine the performance and functional requirements of the product: The first step is determining the functional, performance, and aesthetic requirements of the product. For example, if the product has to have the brand name on top, this aesthetic requirement needs to be listed.

- Choose the materials: The second step is to choose which materials will best meet the needs of the overmolding requirements. It includes selecting the material for the substrate and the overmold material for each layer.

- Consider the substrate design: Substrate design is also an essential part of the process. The substrate should have ribs, texture, and holes to ensure that the overmold material bonds to the material effectively.

- Design the overmold layer: The next step is to design the overmold layer, including the brand name design and any grip surface textures.

- Consider the molding process: After the design elements have been gathered, it is time to optimize the molding design, including the thickness of the mold and the volume of materials to be poured in.

- Create a mold: Before the mold is finalized, a prototype mold needs to be developed. It needs to be tested to ensure the product meets the aesthetic, ergonomic, and performance requirements.

Factors Affecting Overmolding Cost

There cannot be a general estimate of the cost of overmolding. The reason is that the cost depends on many factors. These include the production volume, the complexity of the design, and the materials used. Here are the factors that impact the cost of an overmolding project:

- The complexity of the design: The complexity of the overmolded part also impacts production cost. More complex designs require more intricate molds, which can increase the cost of production.

- Materials used: The materials used in the overmolding process can also impact the cost. Certain materials, such as high-performance plastics or specialty rubbers, are more expensive and increase the price levels.

- Production volume: One of the factors impacting the cost is the production volume. If the overmolding process needs to be automated, a higher price is associated with the project. But a higher volume can lower the per unit cost of production.

- Manufacturing process used: The manufacturing process used can also impact the cost of overmolding. For example, injection molding is often used for high-volume production, while 3D printing or manual casting can be more expensive for smaller production runs.

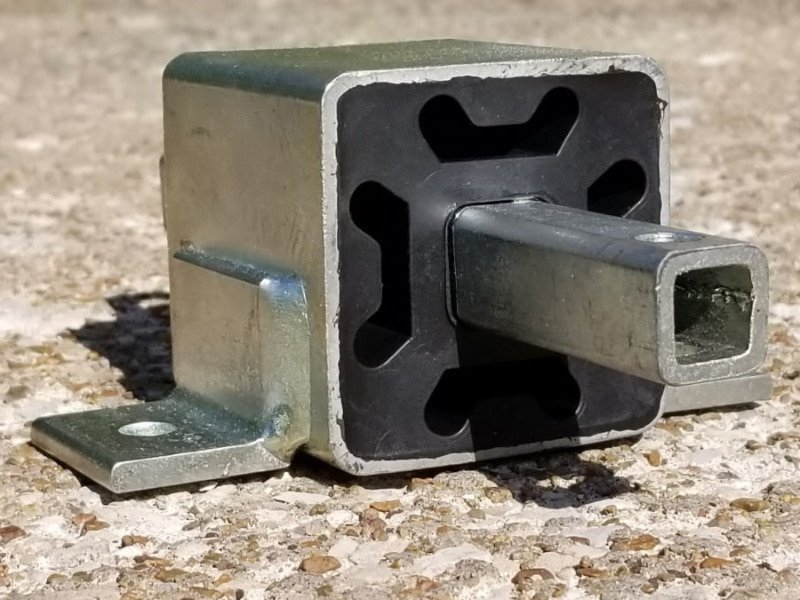

What is the Difference Between Overmolding and Insert Molding?

Insert molding services are a form of injection overmolding. The only difference between over-molding and insert molding is that the pre-formed part is added to the mold before pouring the molding material. The material flows around and between the pre-formed substrate to form a finished product that has better durability and strength than an overmolded component. In overmolding, the material is molded over another material. An example is the rubber part of the toothbrush.

The preformed substrate is either procured from a different facility or manufactured according to the needs of the product. Both overmolding and insert molding are used to add functional features, aesthetic features, or create complex, multi-material parts.

Calculating Injection Molding Cost for Plastic Parts

Conclusion

In conclusion, overmolding provides a reliable way to enhance product ergonomics, durability, and visual appeal. At Zhongde, we specialize in custom overmolding solutions, offering expertise in materials selection, substrate design, and advanced molding techniques. With professional mold design and high-quality production, Zhongde delivers cost-effective and tailored solutions that simplify manufacturing and improve product performance.