Material hardness is a fundamental property that indicates how well a material can withstand forces without undergoing permanent deformation. It is measured through various methods and has significant implications for material selection and application in engineering and custom manufacturing processes. Continue reading and learn hardness types, test measurement, and unit of hardness.

What is Material Hardness?

Material hardness is a fundamental mechanical property that measures a material’s resistance to deformation, indentation, scratching, or penetration. It signifies a material’s ability to withstand external forces without undergoing permanent changes to its shape or structure. In essence, material hardness indicates how resistant a material is to wear, abrasion, and impacts.

Hardness is a critical factor in material selection, as it directly influences a material’s suitability for specific applications. Different materials exhibit varying degrees of hardness, which impacts their performance in diverse scenarios.

Material Selection Service

What Are the Different Types of Material Hardness?

Material hardness can be classified into three main types based on the measurement methods used. Each hardness testing method has its own advantages and is suited for different materials and applications. Here are the different types of material hardness:

Scratch Hardness:

Scratch hardness gauges a material’s ability to resist surface abrasion and scratching. It involves sliding a harder material across the material’s surface, observing its resistance to scratching and wear.

Rebound Hardness:

Rebound hardness assesses material hardness by measuring the rebound height of an impact body dropped onto the material’s surface. This method is suitable for softer materials that may not undergo traditional indentation-based tests.

Indentation Hardness

Indentation hardness examines material resistance by measuring the indentation’s depth or size resulting from a controlled force applied to the material’s surface.

How to Test Material Hardness?

Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests:

The Brinell Test

The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. The diameter of the resulting indentation is measured using a microscope. The Brinell hardness number (HB) is calculated using the load and the diameter of the indentation.

The formula for Brinell hardness is:

Where:

F – force, N

D – indenter diameter, mm

d – indentation diameter, mm

Rockwell Hardness Test

The Rockwell hardness test measures the depth of indentation created by applying a preload and a major load to the material’s surface using a diamond cone or steel ball indenters. The Rockwell hardness number (HR) is determined based on the depth of indentation.

The formula for Rockwell hardness is:

where

N – scale factor depending on the scale used

s – scale factor depending on the scale used

d – depth of permanent indentation compared to minor load, mm

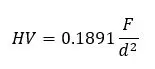

Vickers Hardness Test:

The Vickers hardness test utilizes a diamond pyramid indenter to create an indentation on the material’s surface under a specified load. The diagonals of the indentation are measured, and the Vickers hardness number (HV) is calculated.

The formula for Vickers hardness is

where

F – force, N

d – indentation diagonal, mm

Mohs Hardness Test

The Mohs hardness test is a simple qualitative test that ranks minerals based on their scratch resistance. In this test, a mineral of known hardness is used to scratch another mineral. The relative ability to scratch or be scratched determines the Mohs hardness scale position.

Scleroscope Test

The Scleroscope hardness test involves dropping a diamond-tipped hammer from a fixed height onto the material’s surface. The rebound velocity of the hammer is measured, and the Scleroscope hardness value (HS) is determined.

What Unit is Material Hardness Measured By?

Some engineers often confuse the SI unit of hardness with the SI unit of pressure. The standard international (SI) unit for hardness is N/mm², also called the pascal unit, while pressure uses the SI unit N/m² (or kg·m⁻¹·s⁻²).

Different types of hardness have their own measurement scales, such as Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC), Vickers hardness (HV), and Leeb hardness (HLD, HLS, HLE, etc.). Since the measurement methods differ, the units cannot be directly compared. However, you can use a conversion table to make approximate comparisons between different hardness values. While conversions are not 100% precise, they provide a useful reference.

| HB | HRC | HRB | HV | N/mm² |

|---|---|---|---|---|

| 500 | 53 | 119 | 535 | 5250 |

| 490 | 52 | 118 | 525 | 5140 |

| 480 | 51 | 116 | 515 | 5050 |

| 470 | 50 | 115 | 505 | 4950 |

| 400 | 43 | 108 | 435 | 4250 |

| 350 | 38 | 101 | 385 | 3770 |

| 300 | 33 | 94 | 335 | 3270 |

| 250 | 28 | 88 | 285 | 2790 |

Conclusion

Material hardness isn’t just a measurement; it’s a guiding principle. Proper testing is paramount for optimal material selection. With diverse methods available, Zhongde experts ensure well-informed decisions.