Injection molding stands as one of the most pivotal manufacturing techniques in the plastics industry, enabling the mass production of complex, high-precision parts with remarkable efficiency. Central to this process is the mold itself. The tool that shapes molten plastic into the desired component.

What Is a Mold and Mold Manufacturing?

A mold is a specialized tool designed to shape raw materials into a specific form or product in injeciton molding process. Mold manufacturing refers to the entire process of designing, fabricating, assembling, and testing these molds to ensure they meet precise specifications and can withstand the rigors of production. The quality and durability of the mold directly impact the final product’s accuracy, surface finish, and production efficiency.

Materials Used in Mold Making

In mold making, materials like steel, aluminum, and sometimes plastics or ceramics are commonly used, each bringing its own advantages and limitations. Steel molds are highly durable and can withstand the high temperatures and pressures of large-scale production, making them ideal for long runs where precision and longevity are crucial. However, they are more expensive and require longer manufacturing times. Aluminum molds, while less durable, offer faster and cheaper production, which suits prototyping and low-volume runs where quick turnaround is important.

Other materials such as plastics, ceramics, wood, or foam may be used for very low-volume or prototype molds because they are inexpensive and easy to shape, but they lack the strength and precision needed for mass production.

Mold Manufacturing for Different Molding Processes

The different molding process dictates unique requirements for mold design, materials, and manufacturing techniques.

The molds used in injection molding process must withstand high pressures and temperatures as molten plastic is injected into the mold cavity. Consequently, injection molds are typically manufactured from hardened steel or pre-hardened steel to ensure durability and dimensional stability.

Molds for compression molding are generally simpler in design but must be made from materials that can withstand high temperatures and pressures without warping. Steel molds are common, but depending on the application, aluminum molds may be used for lower-volume production.

Molds used in transfer molding must be designed to accommodate this flow path, often requiring more complex gating and venting systems. The mold manufacturing process emphasizes precision in these flow channels and robust sealing surfaces to prevent flash and ensure part quality.

The molds for blow molding often involve split halves with smooth internal surfaces and require materials that can handle cyclic thermal stresses. Mold making for blow molding focuses on surface finish and thermal management.

Soft molds, made from silicone or rubber, are often used in prototyping or low-volume production across various molding methods due to their flexibility and ease of manufacture.

Molds for thermoforming are typically made from aluminum or other softer metals because the process involves lower pressure. The mold manufacture for thermoforming focuses on creating smooth, accurately contoured surfaces that allow the heated plastic sheet to conform precisely.

The molds used in vacuum forming are often made from wood, aluminum, or composite materials, depending on production volume and complexity. Mold manufacturing for vacuum forming emphasizes surface finish quality and durability to withstand repeated vacuum cycles.

Mold Types and Their Applications

Molds used in plastic manufacturing generally fall into two broad categories, as defined by the types of injection mold: soft molds and hard molds. Soft molds are typically made from pre-hardened steel, aluminum, or other softer materials that do not require heat treatment. Their hardness usually falls below 44 HRC. Hard molds are made from heat-treated, hardened steel with hardness levels often exceeding 48 HRC. Classification of Hard Molds: Single-Cavity, Multi-Cavity, and Family Molds

Single-Cavity Molds

These molds contain one cavity and produce one part per injection cycle. Single-cavity molds are typically used for large or complex parts where precision and surface finish are critical. The manufacturing cost per mold is lower, but the production output is limited, making them suitable for moderate production volumes or specialized components.

Multi-Cavity Molds

Multi-cavity molds feature multiple identical cavities within a single mold base, allowing several parts to be produced simultaneously in each injection cycle. This design significantly increases production efficiency and reduces the cost per part, making it ideal for high-volume manufacturing of smaller, simpler parts.

Family Molds

Family molds contain multiple cavities that produce different parts in the same injection cycle. This approach is useful when a product consists of several components that can be molded together, streamlining assembly processes and reducing cycle times.

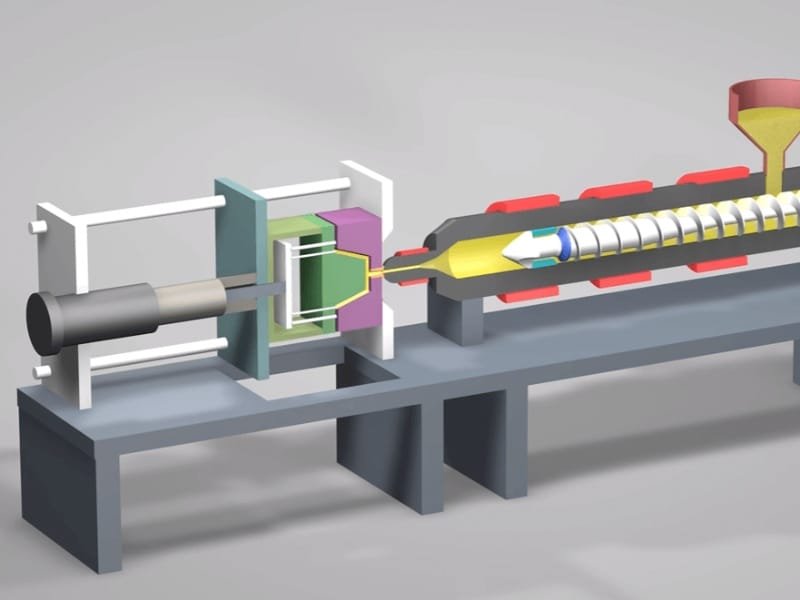

Injection Mold Components

The success of plastic injection mold making hinges on its components, collectively referred to as the injection mold structure, each meticulously designed to ensure precision and functionality. Below are the key parts that define a mold’s performance:

Mold Base: The sturdy framework, typically steel or aluminum plates, that holds all components together, providing structural integrity during high-pressure injection.

Cavity: The fixed part of the mold that shapes the exterior of the plastic part, requiring polished surfaces for flawless finishes.

Core: The movable counterpart to the cavity, forming the part’s interior and often incorporating complex geometries for intricate designs.

Sprue Bushing: A channel that directs molten plastic from the injection machine into the mold, designed for efficient material flow.

Guide Pins and Bushings: These components ensure precise alignment of the mold halves during opening and closing.

Sprue, Runner, and Gate: These form the pathway network for molten plastic to flow from the injection nozzle into the mold cavities. The sprue is the main channel, runners distribute the flow, and gates control the entry into each cavity.

Ejector Pins: Small rods that push the cooled part out of the mold without damage, requiring precise alignment to avoid sticking.

Cooling Channels: Embedded pathways that circulate coolant to regulate mold temperature.

Mold Manufacturing Process

The mold manufacturing process is a meticulous sequence of steps, blending advanced technology with skilled craftsmanship to create precision tools. The key steps include:

- Design: Designers creat a 3D CAD model using software like Mold Wizard or SolidWorks.

- Material Selection: Based on the design complexity, budget and production requirements, appropriate mold materials are selected. en hardened steel, pre-hardened steel, or aluminum.

- Machining: Using CNC (Computer Numerical Control) machines, Electrical Discharge Machining (EDM), and other precision tools, the mold components are machined from the selected materials.

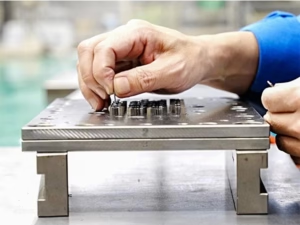

- Assembly: After machining, the mold components—core, cavity, cooling channels, ejector system, and others—are assembled with precision.

- Testing and Refinement: The mold undergoes trial injections to produce sample parts. Technicians inspect for defects like flash or short shots, adjusting the mold—perhaps refining runner systems or polishing surfaces—to achieve perfection.

Equipment and Machinery Used in Mold Manufacture

The mold manufacturing process relies on an array of advanced machinery and equipment, including:

- CNC Milling Machines: For precise shaping of mold components.

- EDM Machines: For intricate detailing and shaping hard-to-machine areas.

- Grinding Machines: To achieve smooth finishes and tight tolerances.

- Drilling and Tapping Machines: For creating holes and threads.

- Assembly Tools: For fitting and aligning mold components.

- Inspection Equipment: Coordinate Measuring Machines (CMM) and other metrology tools to verify dimensional accuracy.

Important Considerations in Mold Design

Effective custom mold design is a balance of engineering, material science, and manufacturing expertise. Key considerations include:

Structural Integrity: The mold must withstand high injection pressures and thermal cycling without deformation.

Cooling Efficiency: Proper cooling channel placement ensures uniform temperature distribution, reducing cycle times and defects.

Proper gate placement: Whether pin, edge, or fan gates, optimizing runner and gate design promotes smooth plastic flow, minimizing turbulence, weld lines, air traps and incomplete fills.

Proper venting design: Small channels (0.02-0.05 mm) allow trapped air to escape, preventing burn marks or voids.

Ejection Mechanisms: Well-designed ejector systems prevent part damage and facilitate quick cycle times.

Draft Angles and Parting Lines: Proper draft angles aid in part release, 1-2 degrees per inch of cavity depth. While parting lines affect mold complexity and aesthetics.

Material Compatibility: The mold material must withstand the molding process’s temperature and pressure, whether it’s thermoplastics for plastic mold making or metals for die-casting.

Maintainability: Designs should allow easy access for cleaning, inspection, and repairs, which is an important aspect of any high-quality custom mold service.

Conclusion

At Zhongde, by leveraging advanced materials, tailored designs, and state-of-the-art equipment, we craft molds that empower industries to produce high-quality components efficiently. From the intricacies of plastic injection mold making to the adaptability of multi-cavity and family molds, our custom injection services ensure performance, flexibility, and reliability.

FAQ

Warping is caused by uneven cooling of the plastic material, leading to deformation or distortion of the part. Optimizing the mold’s cooling system and accounting for the material’s shrinkage properties during the design phase can minimize warping.

Surface defects such as sink marks, blemishes, or rough textures can result from improper temperature, pressure, or cooling time settings. Ensuring uniform wall thickness in part design and adjusting mold temperature and pressure parameters help prevent these imperfections.

Mold misalignment can cause defects along the parting line or produce flash (excess material). Maintaining high precision during mold manufacturing and careful assembly ensures proper alignment and reduces these issues.