Cutting technologies are fundamental in modern manufacturing. There are four cutting technologies dominate: laser cutting, waterjet cutting, plasma cutting, and wire electrical discharge machining (wire EDM). Each method offers unique capabilities, catering to diverse materials, thicknesses, and project demands. Understanding the differences between these methods is key to selecting the right process for your project.

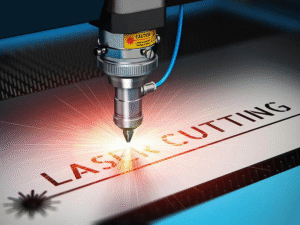

What is Laser Cutting?

Laser cutting uses a highly focused beam of light to melt, burn, or vaporize material along a precise path. This method excels in speed and precision, capable of producing intricate shapes and smooth edges. It is especially effective for thin to medium-thickness materials and allows for additional functions like engraving. However, laser cutting generates heat, which can affect heat-sensitive materials and may limit its use on reflective or thermolabile substances.

What is Water Jet Cutting?

Water jet cutting employs a high-pressure stream (30,000–90,000 psi) of water mixed with abrasive particles to mechanically erode material. Water jet cutters are versatile, capable of cutting a wide range of materials—including metals, composites, ceramics, and even tempered glass—with thicknesses often exceeding 100 mm. It produces smooth edges with minimal post-processing. The trade-off is slower cutting speeds (generally around 20 inches per minute) and slightly less precision compared to laser cutting. Water jet cutting is ideal for thick or heat-sensitive materials where thermal damage must be avoided.

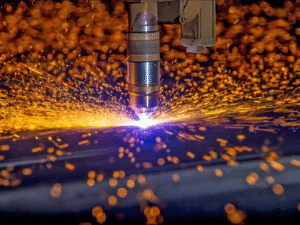

What is Plasma Cutting?

Plasma cutting uses a high-velocity jet of ionized gas (plasma), heated to over 20,000°C to melt and blow away material. Known for high speeds (up to 200 inches per minute), it’s ideal for thick plates (up to 1.5 inches). However, plasma’s rougher edges and slag production, limiting precision (tolerances of ±0.01”–0.03”). The heat-affected zone is larger than with laser or water jet cutting, which can influence the quality of the edge and the material properties near the cut.

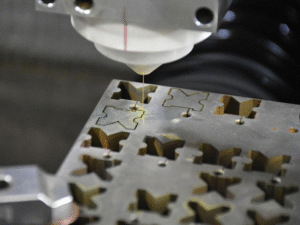

What is Wire EDM Cutting?

Wire Electrical Discharge Machining (EDM) cutting uses a thin, electrically charged wire to erode material through rapid electrical discharges. Wire EDM produces no mechanical forces or heat-affected zones, making it perfect for delicate, high-precision parts such as molds and dies. However, it is slower (20–300 mm²/min) and generally limited to conductive materials.

Material and Thickness Capabilities

The difference between laser cutting and waterjet cutting lies in material versatility and thickness. Laser vs water cutting excels with thin materials (0.12–1.5 inches), cutting metals and non-metals but struggling with reflective surfaces. Waterjet vs laser shines in cutting nearly any material—metals, plastics, stone—up to 12 inches, or even 100 feet in specialized cases. Plasma table vs water jet limits plasma to conductive metals (up to 1.5 inches), with quality dropping beyond 0.5 inches. Wire EDM, like CNC plasma or waterjet systems, handles conductive materials up to 16 inches with exceptional precision. It is also considered a CNC machining method, as the cutting path is digitally controlled for high-precision fabrication.

Comparative Laser Cutting vs Water Cutting vs Plasma Cutting vs Wire EDM Cutting

To better understand the differences among these cutting technologies, the following table provides a comparison of their key characteristics.

| Aspect | Laser Cutting | Waterjet Cutting | Plasma Cutting | Wire EDM Cutting |

|---|---|---|---|---|

| Principle | Focused laser beam melts material | High-pressure water/abrasive erodes | Hot plasma jet melts conductive metals | Electrical discharges erode via wire |

| Precision | High (±0.002” tolerance) | Moderate (±0.005”–0.008” tolerance) | Lower (±0.01”–0.03” tolerance) | Exceptional (tenths of a thousandth) |

| Cutting Speed | Fast (20–70 in/min) | Slow (1–20 in/min) | Very fast (up to 200 in/min) | Very slow (20–300 mm²/min) |

| Heat-Affected Zone | Small | None | Large | None |

| Material Versatility | Metals, plastics; reflective issues | Nearly all materials | Conductive metals only | Conductive materials only |

| Max Thickness | ~1.5” | ~12” (or more in niche uses) | ~1.5” (best <0.5”) | ~16” |

| Edge Quality | Smooth, possible HAZ | Clean, no HAZ, slight taper | Rougher, slag possible | Extremely precise, no stress |

| Applications | Thin metals, signage | Thick, heat-sensitive materials | Thick metals, structural parts | Molds, micro-precision parts |

Cost Considerations

Laser cutting machines generally have lower initial costs than water jet systems, with equipment prices ranging from $8,000 to $250,000, while water jet cutters can cost $60,000 to $450,000. Operating costs for laser cutting include electricity and occasional laser tube replacements, whereas water jet cutting involves consumables like abrasives and more maintenance. Plasma cutters tend to be more economical for thick metal cutting but offer less precision. Wire EDM machines are costly and slower but indispensable for ultra-precise applications. When comparing water jet vs laser cutting cost, laser cutting is often cheaper for thin materials and high-volume production, while water jet cutting is more cost-effective for thick or heat-sensitive materials.

Conclusion

Selecting the right cutting technology involves balancing multiple factors beyond just the technical specifications. Considerations such as the nature of the project, desired finish quality, production volume, and long-term operational costs all play crucial roles. By understanding the unique strengths and limitations of each method, Zhongde can optimize efficiency and achieve superior results tailored to their specific applications through its custom manufacturing services designed for diverse project needs.