Compression molding is a versatile and widely utilized manufacturing process in modern engineering and production, especially valued for producing durable components from a variety of materials including thermosets, thermoplastics, rubbers, silicones, and composites. This article offers a comprehensive exploration of the compression molding process and the related knowledges.

What is Compression Molding?

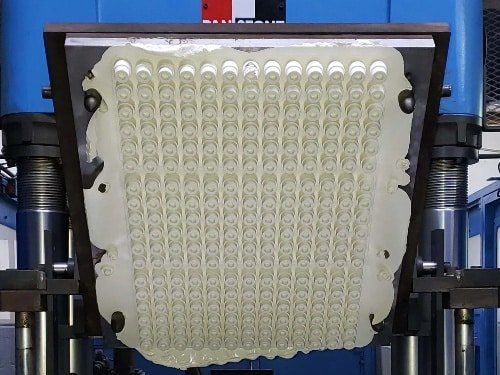

Compression molding (also known as press molding or pressure molding) involves placing a pre-measured charge of molding material into a heated mold cavity, which is then closed and subjected to heat and pressure to form a specific shape. The heat softens or cures the material, enabling it to fill the mold and solidify into a finished product once cooled.

How Compression Molding Works?

Whether it’s rubber compression molding, plastic compression molding, or silicone compression molding, The following procedures all apply with compression molded parts:

1.Material Preparation

The raw material could be in the form of pellets, sheets, or preforms. The molding compound, whether rubber, silicone, thermoset plastic, or composite, is pre-measured and often preheated (depending on the material) to optimize flow and cure characteristics.

2.Mold Creation

Molds, usually made of steel or aluminum, consist of two halves—the upper and lower mold—forming a cavity that matches the desired product geometry.

3.Mold Loading

The prepared charge is placed into the cavity of the lower mold half. Accurate measurement is important to prevent underfilling or material flash.

4.Compression and Curing

A compression molding press closes the mold, applying significant pressure (100-500 psi) and heat to shape the material. In rubber compression molding, the material cures, undergoing a chemical transformation to achieve its final, rigid form.

5.Demolding and Finishing

Once cured or cooled, the mold opens, and the part is removed. Excess material, known as flash, is trimmed, and the part undergoes quality checks.

Types of Compression Molding Presses

Several compression molding presses exist, different presses cater to specific needs.

Industrial Hydraulic Compression Molding Machines

These are the most common machines for large-scale, high-pressure molding applications. Leveraging hydraulic systems, they provide precise control over pressure and temperature. They are enbles molding of large, heavy, and complex parts.

Benchtop Compression Molding Machine

Benchtop machines are compact and suited for R&D, prototyping, and small to medium batch production. These presses often support smaller parts such as test samples or experimental designs.

Cold (Heatless) Compression Molding Machines

This category of machines applies pressure without integrated heating elements. They are ideal for materials sensitive product properties.

Wet Compression Molding Machines

Wet compression molding machines are designed specifically for composite materials impregnated with liquid resins or prepregs. Heat and pressure activate resin flow and curing within the mold, leading to strong, lightweight components with high fiber-to-resin ratios.

Compression Molding Materials

The compression molding is compatibility with a wide range of materials, each offering unique properties for specific applications. Below, we explore the compression molding material categories.

Thermosetting Materials

Common thermosets include: Epoxy, Phenolic, Melamine, Urea-Formaldehyde, Polyester, Silicone, etc. These materials undergo irreversible curing when heated and provide high strength, excellent dimensional stability, and heat resistance.

Thermoplastics

Common thermoplastics include: PE, PP, PVC, PA, PS, etc.

Thermoplastics lack the heat resistance of thermosets, however they offer recyclability and flexibility. They often used in compression plastic moulding for relatively simpler shapes with high precision.

Elastomers

Common elastomers include: NR, CR, VMQ, NBR, EPDM, etc.

These materials excel in high flexibility and elasticity with strong resistance to abrasion and aging. Rubber products made by rubber compression molding include seals, gaskets, and vibration dampers.

Other Materials

Beyond traditional polymers, compression molding composites material like carbon fiber, fiberglass, Bulk Molding Compounds (BMC), and Sheet Molding Compounds (SMC) are used for high-strength, lightweight parts.

Types of Compression Molds

The compression mold design is pivotal to achieving high-quality parts. Different mold types cater to varying levels of precision and complexity:

Flash Molds

Flash molds are cost-effective and allow excess material to escape as flash during compression. They are ideal for simple shapes in rubber compression molding but require post-molding trimming.

Positive Molds

Positive molds ensure precise material volume control, minimizing waste and producing high-accuracy parts. They are used in compression molding composites for complex geometries requiring tight tolerances.

Semi-Positive Molds

Balancing cost and precision, semi-positive molds combine features of flash and positive molds. They are suitable for moderately complex parts in plastic compression molding.

How to Create Molds for Compression Molding?

The creation of molds for compression molding relies on advanced technologies to ensure durability, precision, and compatibility with the rigorous demands of the compression molding technique.

Die Casting

Die casting produces durable molds by injecting molten metal (e.g., steel or aluminum) into a die, offering high dimensional accuracy. It’s widely used for rubber compression molding and plastic compression molding molds, balancing cost and durability.

CNC Machining

CNC machining carves mold cavities with tolerances of ±0.01 mm, ideal for intricate compression molding composites or silicone compression molding molds.

3D Printing

3D printing (e.g., SLA, SLS) enables rapid prototyping of molds for plastic compression molding using high-temperature resins. It’s cost-effective for small parts or heatless applications, allowing quick design iterations.

Compression Molding Mold

Advantages and Disadvantages of Compression Molding

Advantages of Compression Molding

Suitable for Complex and Large Parts: Compression molding is well-suited to forming parts with complex shapes and large dimensions, which can be challenging for other molding methods.

Versatile Material Compatibility: This method can process a wide range of materials, including thermosets, thermoplastics, elastomers (such as rubber and silicone), and composites.

Cost-Effective Tooling: Mold tooling for compression molding is generally less expensive than that for injection molding. This lowers up-front investment, especially for medium to large-sized parts and prototype runs.

Low Material Waste: Because material is precisely measured and placed in the mold cavity, excess waste and scrap are minimized compared to some other processes.

Strong, High-Quality Parts: The resulting parts often exhibit good mechanical properties and consistent density, especially when using fiber-reinforced or composite materials.

Allows for Insert Molding and Multi-Material Designs: Engineers can incorporate inserts or combine materials during the process, allowing for hybrid parts or components with embedded hardware.

Energy Efficient: The process typically involves lower cycle temperatures and pressures compared to injection molding, resulting in potential energy savings.

Disadvantages of Compression Molding

The cycle times are generally longer than those of injection molding, making it less ideal for extremely high-volume production. The process requires precise charge preparation and skilled operation to avoid defects such as air entrapment, incomplete filling, or excess flash. Dimensional accuracy can be less consistent for highly detailed or thin-walled parts, and automation is more challenging due to the manual handling of charges and molded parts. It also not be suitable for parts with intricate undercuts, and secondary trimming might be needed to remove excess material from the finished part.

Compression molding offers several benefits, especially for large or complex parts, but it’s important to weigh them against its limitations. For a deeper analysis, see our in-depth guide to the advantages and disadvantages of compression molding.

Applications of Compression Molding

- Automotive: Gaskets, seals, dashboards, bumpers, tire components.

- Aerospace: Composite panels, structural supports, insulation parts.

- Consumer Goods: Kitchenware, appliance housings, electrical insulators.

- Medical: Prosthetic components, device casings, biocompatible seals.

- Industrial: Vibration dampeners, bushings, conveyor belt parts.

Compression Molding Defects

Defects in compression molding can compromise part quality but are manageable with proper process control. The table below outlines common issues, their causes, and solutions:

| Defect | Cause | Solution |

|---|---|---|

| Flash | Overcharge or improper mold closure | Adjust material volume, improve mold sealing |

| Voids | Insufficient venting | Increase pressure, optimize material placement |

| Warping | Uneven cooling or temperature control | Control cooling rates, adjust mold design |

| Burn Marks | Excessive heat or prolonged curing | Lower temperature, reduce cycle time |

| Incomplete Fill | Insufficient material or low pressure | Increase material volume or pressure |

| Delamination | Poor material prep or curing settings | Improve material mixing; optimize cycle |

Compression Molding Product Design Guide

To maximize the benefits of compression molding, designers must adhere to specific guidelines:

Uniform Wall Thickness: Maintain uniform thickness (2-6 mm) to ensure consistent material flow and minimize defects.

Appropriate Draft Angles: Incorporate 1-3° draft angles to facilitate part release from the mold without damaging parts.

Adequate Radii and Fillets: Use rounded corners (minimum 1 mm radius) to reduce stress concentrations and improve material flow.

Material Selection: Choose materials based on application requirements, such as thermal resistance, mechanical strength, or elasticity.

Consider Tolerances: Design for achievable tolerances (e.g., ±0.1 mm for precision molds) and account for material contraction during cooling to balance cost and quality.

Proper Venting: Prevent trapped air pockets and voids.

Undercuts: Avoid complex undercuts to simplify compression mold design and reduce production costs.

Conclusion

Compression molding is a versatile and cost-effective manufacturing process, ideal for producing high-quality parts across industries. Leveraging advanced compression mold design technologies ensures precision and durability in creating products made by compression moulding. Zhongde Company offers professional compression molding services and compression molding material selection, delivering tailored solutions to meet diverse needs with efficiency and reliability.

FAQ

Industry standards vary by material and application, mostly from ASTM and ISO.