Compression molding of composites is a highly effective manufacturing technique for producing durable and high-performance parts across various industries. This process involves applying heat and pressure to composite materials, which are then formed into the desired shape. Over the years, compression molding has gained significant importance, especially for applications requiring lightweight, strong, and heat-resistant components.

Materials Used in Compression Molding Composites

The materials in compression molding composites consist of fibers and resins that combine to form durable parts. Fibers provide structural support, while resins bind them together during the curing process.

Preparation involves measuring and mixing components to achieve the desired properties.

- Prepreg compression moulding uses pre-impregnated fibers where the resin is already applied and partially cured, allowing for easy handling and precise placement in the mold. In prepreg compression moulding, the material is stored at low temperatures to prevent premature curing, and sheets are cut to fit the mold.

- Wet compression molding involves mixing dry fibers with liquid resin just before loading them into the mold. Wet Compression molding composites required controlled resin viscosity to ensure even distribution during pressing.

Common materials include:

Carbon Fiber Compression Molded Components: Used for high-strength applications due to its low weight and high modulus.

Glass Fiber Compression Molding Parts: Provides cost-effective reinforcement with good corrosion resistance.

Aramid Fiber (Kevlar): Offers impact resistance for protective components.

Epoxy Resin: A thermoset resin known for strong adhesion and heat resistance.

Polyether Ether Ketone (PEEK): A thermoplastic resin that withstands high temperatures.

Polyphenylene Sulfide (PPS): Provides chemical resistance for industrial uses.

Phenolic Resin: Used for flame-retardant properties in electrical insulation.

Vinyl Ester Resin: Offers corrosion resistance for marine environments.

The Compression Moulding Process for Composites

The compression moulding process for composites follows a sequence of steps to transform raw materials into finished parts.

Step 1. Material Preparation

The first step in composite compression molding is the preparation of the material. In most cases, composite materials used in molding are either pre-impregnated with resin (prepreg) or manually impregnated with resin before the molding process.

Step 2. Mold Heating

Once the composite material is prepared, the next step is mold heating. The mold is typically preheated to a specific temperature that matches the requirements of the composite material being used.

Step 3. Material Placement

After the mold is preheated, the composite material is carefully placed inside the mold cavity. Depending on the part’s design, additional materials such as release agents may be used to prevent the part from sticking to the mold during the curing process.

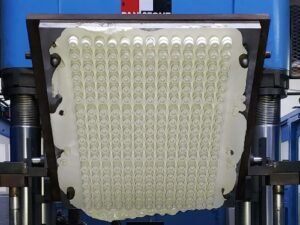

Step 4. Mold Closing and Compression

Once the material is placed, the mold is closed, and pressure is applied. The pressure ensures that the composite material fills the mold completely, taking the desired shape.

Step 5: Curing and Dwell Time

Maintain heat and pressure for the curing period, until fully solidify the part. The exact temperature and pressure requirements depend on the type of composite material used.

Step 6. Cooling and Demolding

Once the composite part has been fully cured, the mold is allowed to cool before it is opened. Open the mold and remove the part, often using automated ejectors.

Step 7: Post-Processing and Trimming

Trim excess material, known as flash, from the edges. Perform inspections for dimensions and quality, and apply any necessary coatings or finishes.

Industries Using Composite Compression Molding

Compression molding of composites is used in a wide range of industries, each with specific performance and material requirements.

- Aerospace: Aircraft wings, fuselage components, and structural elements.

- Automotive: Bumpers, body panels, hoods, engine covers, and chassis components.

- Electronics and Electrical: Housings, covers, and insulation materials for electronic devices and electrical components.

- Marine: Boat hulls, decks, and other components.

- Oil and Gas Sector: Corrosion-resistant pipes and fittings

The Future of Compression Molding for Composites

As industries continue to push for stronger, lighter, and more durable materials, the demand for composite compression molding is growing. Advances in material science, including the development of new resins and fibers, are offering more efficient and cost-effective molding processes. In particular, the aerospace and automotive industries are likely to see continued growth in the use of compression-molded composite parts. Moreover, as automation technologies continue to advance, the precision and efficiency of compression molding processes will improve, further expanding their use in high-performance manufacturing.

Conclusion

Zhongde provides customized services for compression molding composites, focusing on tailored solutions for various applications. Using both prepreg compression moulding and wet compression molding, Zhongde handles projects from prototypes to large-scale production.