Bonding Rubber to Plastic Parts

Zhongde provide rubber to plastic bonding services to meet your specific needs. Through overmolding, we develop the right elastomers and chemical adhesives required to achieve optimal part performance.

- All uploads are secure and confidential!

Custom Products

- Custom Rubber Parts

- Rubber Parts

- Rubber Bonding Metal Parts

- Rubber with Fabric Parts

- Rubber Bonding Plastic Parts

- Custom Plastic Parts

- Plastic Parts

- Plastic Bonding Metal Parts

- Custom TPE Parts

- TPE Parts

- TPE Bonding Metal Parts

- TPE Bonding Plastic Parts

- TPE Bonding Rubber Parts

- Custom Machining Parts

- Plastic CNC Machining Parts

- Metal CNC Machining Parts

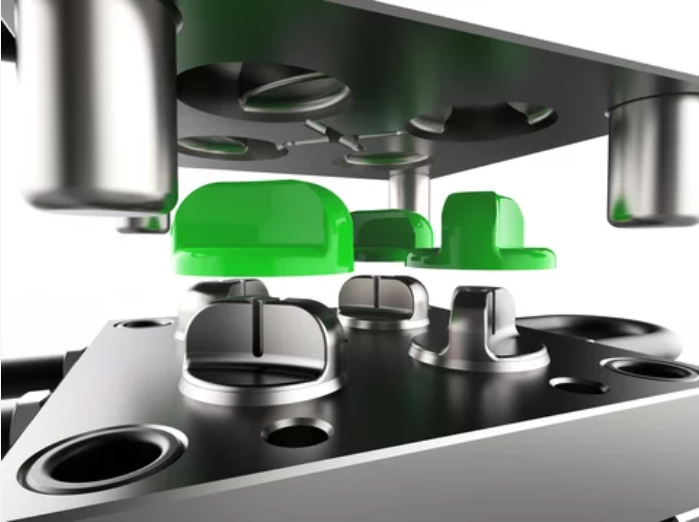

What Are Rubber to Plastic Bonding Parts?

Bonding rubber to plastic is a complex process due to the material’s sensitivity to heat and pressure. However, plastic is widely used for its lightweight, cost-effectiveness, and structural stability. With extensive material expertise and proven bonding techniques, over-molding manufacturing, Zhongde ensure strong and durable rubber-to-plastic bonding for a wide range of applications.

Rubber to Plastic Bonding Parts Display

The following are some of the rubber bonding plastic parts we have made. Please note they are only for displaying our product range and shape, but not for sale. Send us drawings or samples to evaluate your custom project.

Silicone Bonding Plastic Suction Cup

Silicone bonding plastic suction cup is produced with advanced molding technology. We can customize any special design suction cup, just send us your drawings or samples.

Rubber Coating Plastic Pulley

OEM rubber coating pulley with plastic bearing inside. Rubber material has good wear resistance and can extend the life time of pulley. The plastic bearing in the middle plays a supporting role and reduces the weight compared to metal materials.

PTFE Coated Gasket

PTFE coating enhances corrosion resistance, making it suitable for a wide range of aggressive chemicals. The base material is typically EPDM, which provides elastic recovery, low seating stress, and long sealing life.

OEM Encapsulated O-ring

Encapsulated O-rings combine the chemical resistance of PTFE with the elasticity of rubber. If you need custom O-rings with rubber-like flexibility but require far stronger chemical resistance than standard rubber can provide, this type is an ideal solution of chemical industry.

Bonding Rubber to Plastic Process

Just upload your drawing and choose the right rubber and plastic materials — we’ll take care of the rest. Our process ensures strong rubber-to-plastic bonding by optimizing material compatibility, surface treatment, and molding conditions for reliable flexibility, strength, and sealing performance.

Rubber on Plastic Service

- Demand confirmation and material selection

- Design and process evaluation

- Surface treatment and mold making

- Production and quality control

What Do You Get?

- Material matching expertise

- Structure and process synergistic optimization

- Efficient surface treatment technology

- From mold development to bonding molding

- Quick proofing and batch delivery

Custom Product in Various Application

It is easy to fill the form.

Better Quality, Faster Delivery

From design to final parts, from rapid prototyping to mass production, Zhongde's one-stop service meets your needs.

Upload your design drawing and all uploads are secure and confidential!

Upload your design drawing and all uploads are secure and confidential!