On-demand Manufacturing for

Custom Automotive Parts

Home » Application » Automotive Custom Moulding

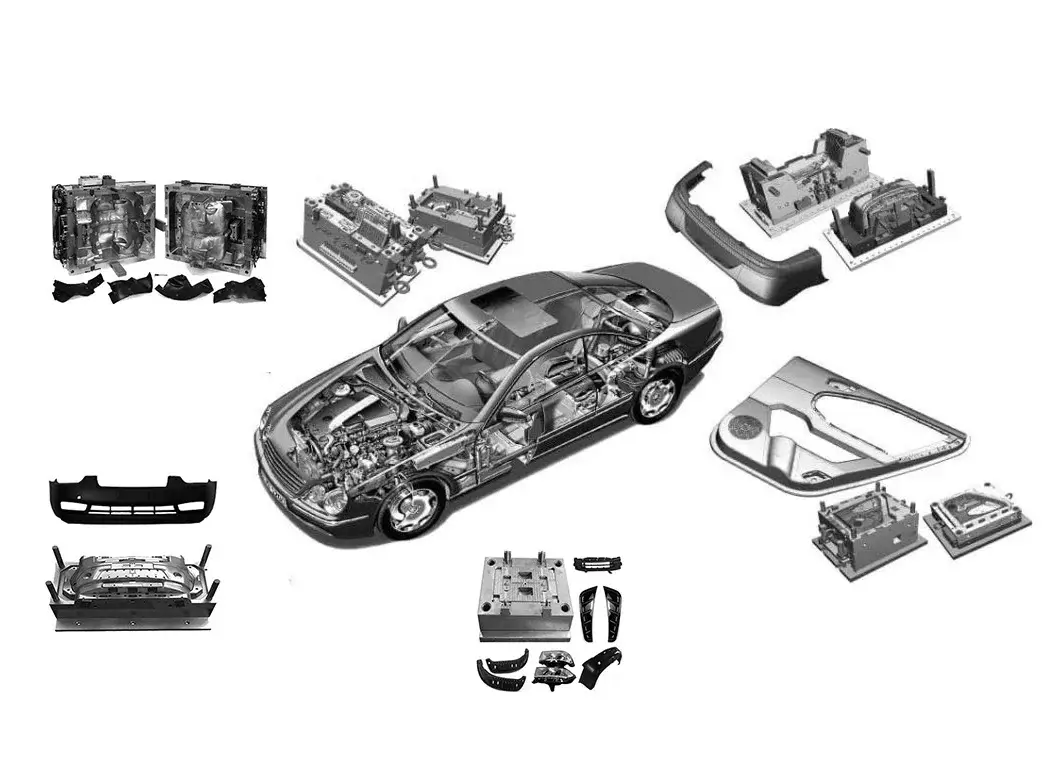

Our Automotive Parts Manufacturing Solutions

Over the past 40 years, the automotive industry has long been Zhongde’s largest business sector. We understand that automotive manufacturing demands ever-higher standards for performance, safety, and efficiency, we continually address the complex demands and challenges in vehicle and component production through our customized manufacturing solutions.

From developing and testing prototypes for cars, trucks, and other vehicles to mass-producing precision automotive parts, we provide manufacturing services that meet stringent industry standards from mold to production.Automotive Molding Parts Manufacturing Capabilities

As an automotive component manufacturer, We provide automotive component solutions to a wide range of buyers, including Tier 1 and Tier 2 suppliers, OEMs, and vehicle manufacturers. Our services span multiple countries across Asia, Europe, and the Americas, with each process tailored to the specific requirements of our clients.

Custom Injection Molding Service

Zhongde has developed a one-stop solution from mold designing and rapid prototyping to mass production. We improve product accuracy and meet the custom requirements of complex-shaped parts.

Custom Compression Molding Service

We use high-strength, precision, heat-resistant metal molds to ensure product quality. Through compression molding, we achieve efficient production with precise, smooth-finished parts.

CNC Machining Service

Get custom CNC machining prototypes and production parts with high quality. We provide expert engineering reviews. Dozens of materials and finishes are available.

Cast Molding Service

Using cast molding, we produce small batches of accurate parts, following confirmed drawings or samples. Should any discrepancies occur, we make adjustments to ensure customer satisfaction.

Automotive Parts We Manufactured

With our on-demand manufacturing, we produce a wide range of custom automotive plastic and rubber, metal parts, capable of fulfilling complex car component designs and precise performance standards.

Interior Part

Custom interior parts with precise assembly, wear resistance.

Body Components

Weather-resistant exterior parts built for impact strength and lasting finish.

Electrical Components

High-precision plastic and rubber electronics with insulation and safety.

Electric Vehicle Parts

Durable EV parts with electrical safety and heat resistance.

Lighting Components

Heat-resistant lighting parts offering clear optics and secure sealing.

Air Intake Parts

Durable air intake parts providing precise fit and reliable airflow.

Material Used in Custom Automotive Molding

With extensive experience in plastics, rubber and metal, we specialize in utilizing glass fiber, carbon fiber, and other reinforcement options to provide lightweight yet high-strength and durable options for automotive interior, exterior, and underhood components.

Rubber Materials

- NR

- NBR

- EPDM

- FKM

- Silicone

- TPE

- TPU

- PU

Plastic Materials

- PA

- POM

- PC

- ABS

- PP

- PE

Metal Materials

- Aluminum Alloys

- Steel

- Stainless Steel

- Copper

- Brass

Put Your Automotive Parts into Production Now!

Our sales team will contact you within 24 hours. We are glad to answer your questions。

Your Partnership in Automotive Parts Manufacturing

Industry Expertise

Decases of industry expertise in injection molding, delivering high-quality parts with precision and reliability. Trust our experience for your project's success

Flexible Customization

We offer customized solutions tailored to your unique injection molding needs. Our flexible approach ensures we can accommodate design modifications, material preferences, and production requirements with ease.

Collaorative Approach

We believe in a collaborative approach, working closely with our clients to understand their specific requirements and goals. Together, we achieve successful outcomes through effective communication and shared expertise.

Auto Part Manufacturing is Faster with Zhongde!

Very considerate service, many problems encountered during the order process, their sales staff can alwavs reply to me in the first time, and provide effective solutions.

Zhongde' s engineers are very professional. When l have doubts about my customized products, they put forward some suggestions for improvement on the material and design of the products, which helped me to improve my design.

Reliable supplier. Although we have time lag. they can always solve any problems for me in time. And they can provide customized all kinds of spare parts we want, very convenient.

Very professional manufacturer. Our production was ofter halted because the previous manufacturer can not meet increasing demand. Then their engineers came up with new designs for our products and solved our problems.